Construction method of flexible socket common pipe trench

A construction method and joint pipe technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as safety, quality accidents, long total length of pipe trenches, and impact costs of pipe trenches, so as to reduce labor intensity and reduce operating costs. The effect of high efficiency and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

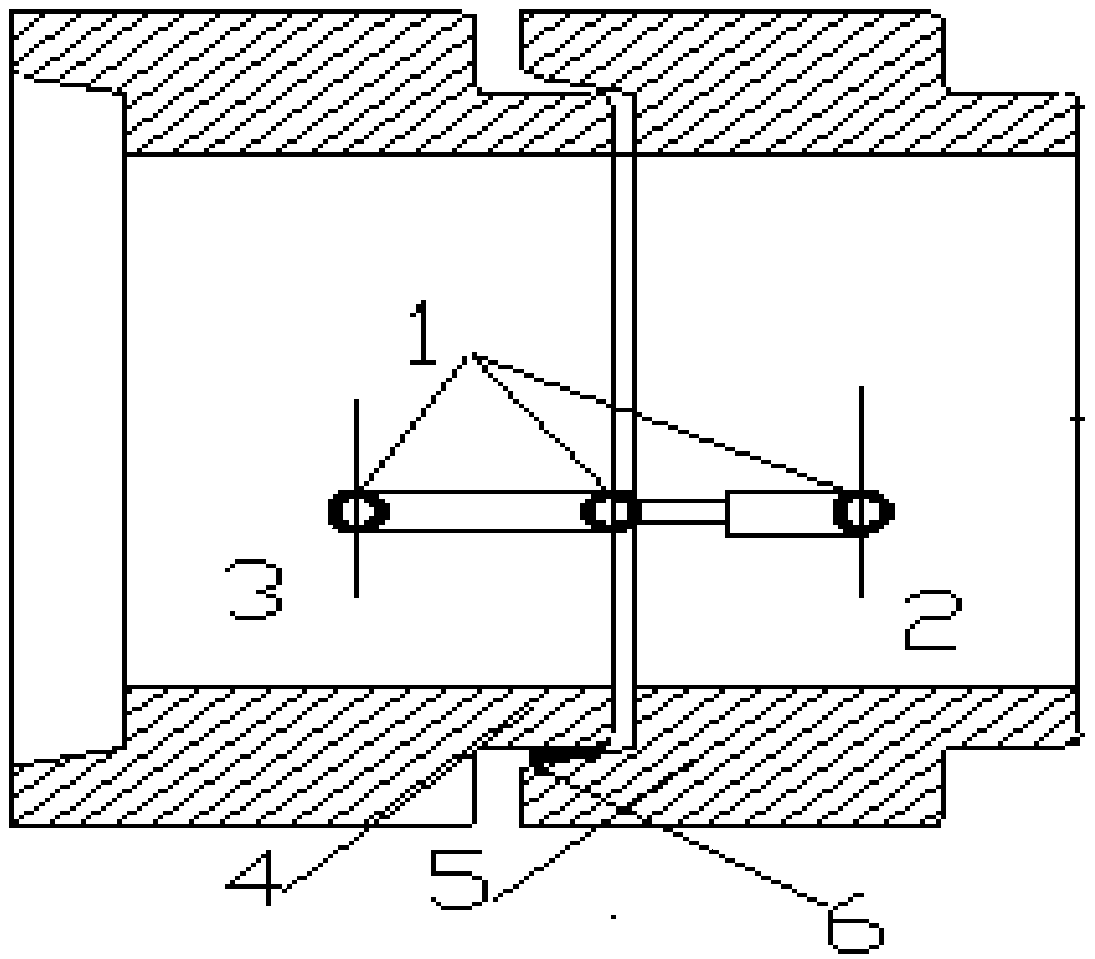

Image

Examples

Embodiment Construction

[0034] The method of the present invention will be described below through specific examples, but the present invention is not limited thereto. Experimental methods described in the following examples, if no special instructions, are conventional methods; said reagents and materials, if no special instructions, can be obtained from commercial sources, and the following examples are not intended to limit the scope of the present invention , all equivalent implementations or changes that do not deviate from the present invention shall be included in the protection scope of this patent.

[0035] Embodiments The construction method of the flexible socket-type common pipe trench includes the following steps:

[0036] S1: Prefabrication of the common pipe trench, transportation and visual inspection of the common pipe trench when entering the site:

[0037] S101: Production and processing of steel bars: the outer surface of steel bars is clean, free of rust, paint, and oil; the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com