Stress-controller multi-level-open anchor stock and anchor construction method

A technology of stress control and bolting, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of uneconomical anchoring force effect, waste material stability, high mortar strength requirements, etc., to achieve a large anchoring influence range and convenient on-site organization , Improve the effect of anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

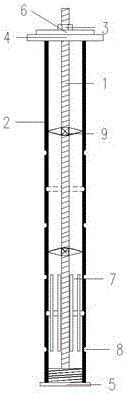

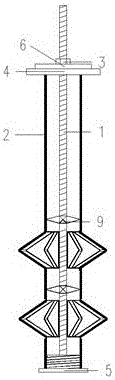

[0061] Manufacture the stress-controlled expansion bolt, where N=3, M=6, that is, the casing 2 assembly is composed of three casings 2, and there are 6 slits on each casing 2, and the bottom of the maximum size decreases upward when it is opened , the opening sequence is bottom priority and upward. The specific steps are:

[0062] S1: Process slits, select three-section casing 2 of different lengths according to requirements, process 6 slits at predetermined positions, divide the slit area of casing 2 into 6 strips, and mark the casing 2 with the largest slit length It is L1, the sleeve 2 with the smallest slot length is marked as L3, and the slot length in the middle is marked as L2. L3 is the bottom sleeve 2.

[0063] S2: Processing groove 8, processing groove 8 at the upper and lower ends and the middle position of each strip of each section of casing 2, processing the groove 8 at the upper and lower ends on the outer wall of casing 2, and processing the middle groove 8...

Embodiment 2

[0070] Use the stress control expansion bolt in embodiment 1 to carry out construction, such as Figure 7 shown. The surface of the bolt casing 2 is rough with patterns, and each section of the casing 2 is processed with an expansion joint 7 at the set position. Through the expansion joint 7, the section of the casing 2 can be divided into six strips, and each section has three strips. There are two grooves 8, and the strip can be bent and opened along the grooves 8, and the positions of the grooves 8 are different in the slot length of each section of the sleeve pipe 2, and the maximum size of the bottom of the opening decreases upwards. The depth of the groove 8 of the casing 2 near the base is 1 / 2 of the thickness of the pipe wall, and the depth of the groove 8 of the casing 2 decreases in turn, and the depth of the groove 8 of the uppermost casing 2 is 1 / 3 of the thickness of the pipe wall. The tube 2 is connected to the base 5 through threads, the three-section casing 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com