Clothes weighing method of roller washing machine

A technology for drum washing machines and washing machines, which is applied to the control devices of washing machines, other washing machines, washing devices, etc., which can solve the problems of large laundry weight errors, motor failure to track the set speed, and neglect, etc., to improve weighing accuracy, The effect of reducing power consumption and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

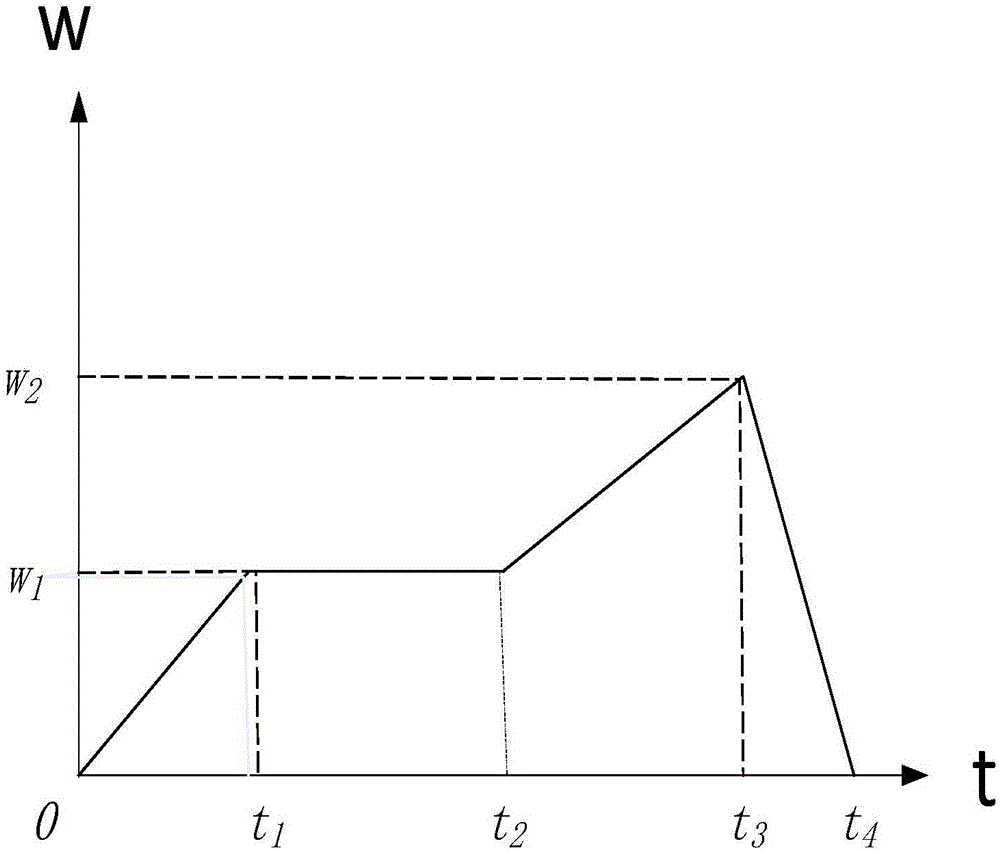

[0022] Such as Figure 1 ~ Figure 3 As shown, a method for weighing clothes in a drum washing machine. The drum washing machine includes a main control board, a driver, and a motor electrically connected to the driver. The clothes weighing method is as follows:

[0023] A. When the driver of the drum washing machine receives the clothes detection command sent by the main control board of the drum washing machine, set the motor speed w 1 , the driver of the drum washing machine controls the motor after t 1 From rest with acceleration a 1 Accelerate to speed w 1 ;

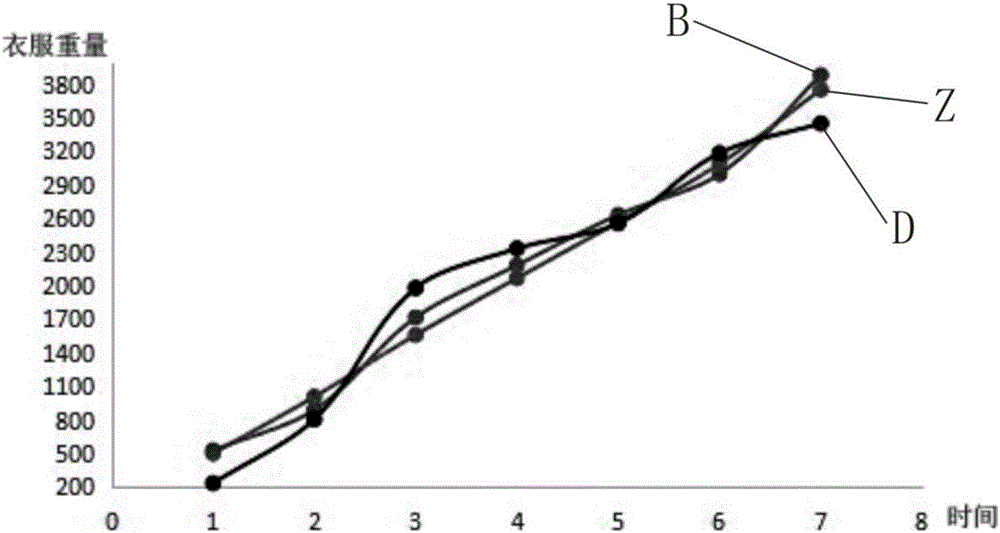

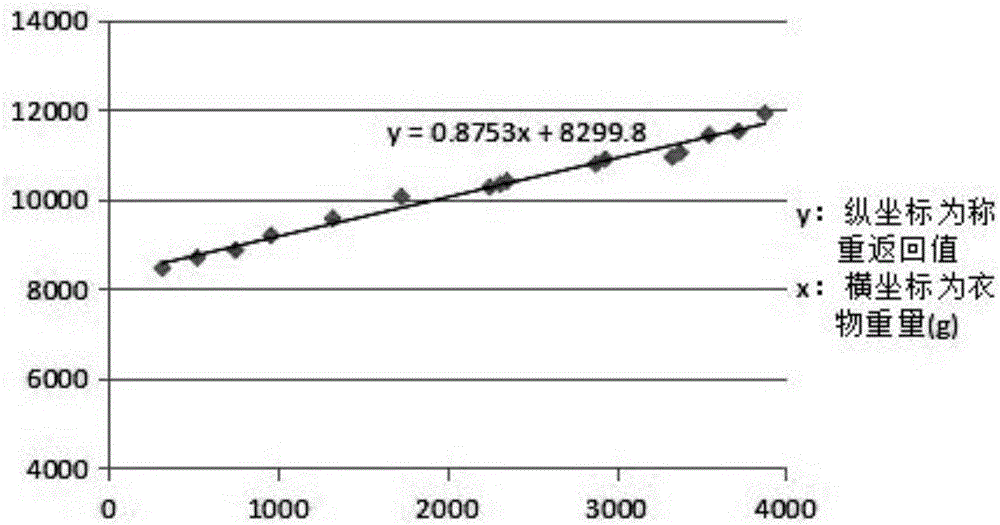

[0024] B. The driver of the drum washing machine controls the motor to rotate at a speed of w 1 Stable running time (t 2 -t 1 ), during this process, the main control board of the drum washing machine obtains the peak phase current of the motor and the eccentric value of the motor speed P imbalanc∈ , motor speed eccentric value P imbalanc∈ Accelerate the motor speed of the drum washing machine from 0 to the s...

Embodiment 1

[0033] Such as Figure 1 ~ Figure 3 As shown, a method for weighing clothes in a drum washing machine. The drum washing machine includes a main control board, a driver, and a motor electrically connected to the driver. The clothes weighing method is as follows:

[0034] The first step is to put clothes into this washing machine; when the driver of the drum washing machine receives the clothes detection command sent by the main control board of the drum washing machine, set the motor speed w 1 , the driver of the drum washing machine controls the motor after t 1 From rest with acceleration a 1 Accelerate to speed w 1 ;

[0035] In the second step, the driver of the drum washing machine controls the motor to rotate at a speed of w 1 Stable running time (t 2 -t 1 ), during this process, the main control board of the drum washing machine obtains the peak phase current of the motor and the eccentric value of the motor speed P imbalanc∈ , motor speed eccentric value P imbala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com