Method for rapid preparation of nimoo4/c nanofibers

A nanofiber, fast technology, applied in the field of electrochemistry, can solve the problems of insufficient electrochemical stability, insufficient capacitance, poor rate performance, etc., and achieves the effects of good cycle stability, easy operation and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

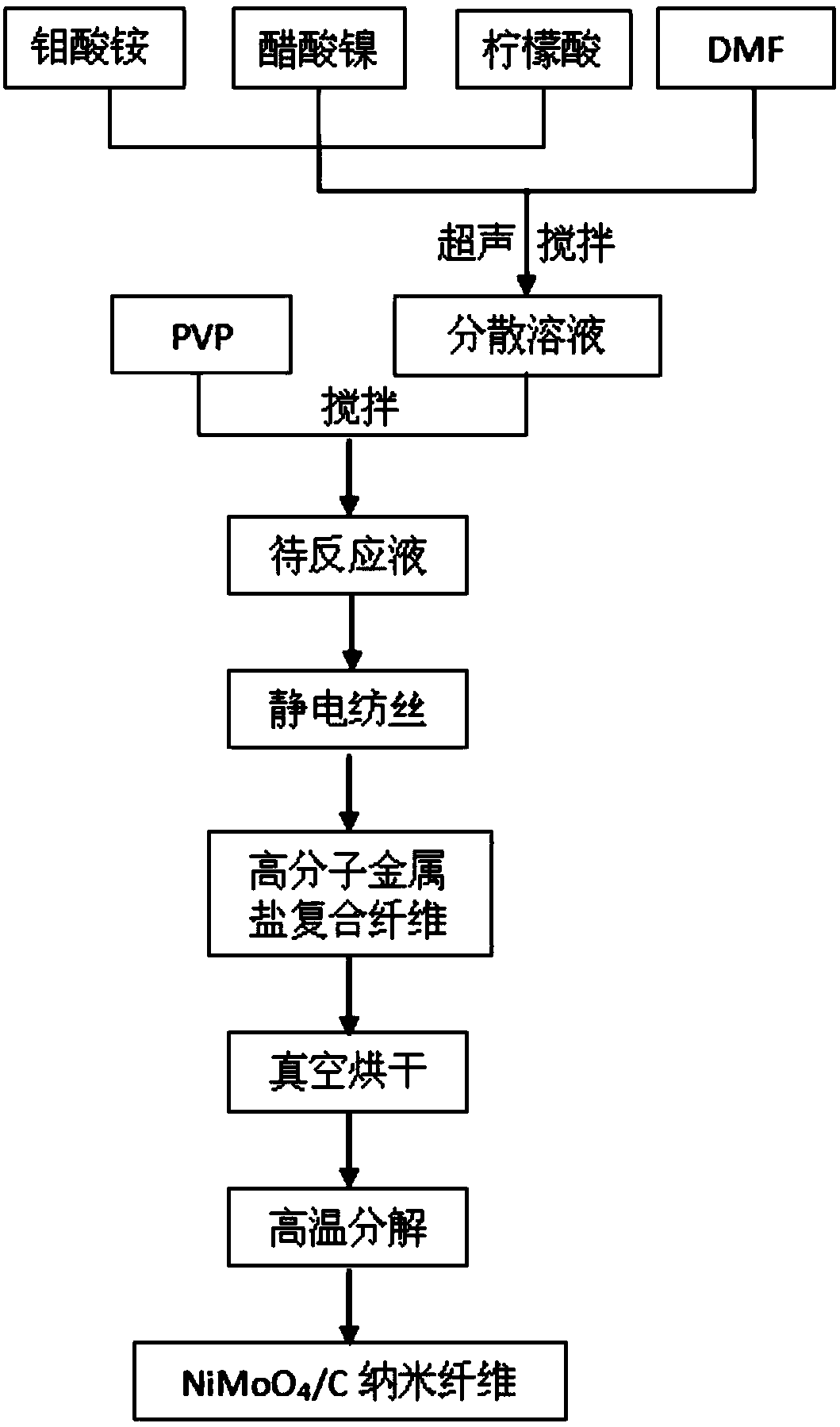

Method used

Image

Examples

Embodiment 1

[0018] Step 1: Weigh (NH 4 ) 6 Mo 7 o 24 4H 2 O 0.3708g, Ni(Ac) 2 4H 2 O 0.5226g, citric acid 0.3152g, join in 10ml DMF solvent, ultrasonic vibration 10min, stir to obtain green transparent dispersion solution, the mass percentage that metal salt solute accounts for total solution is 7.5%;

[0019] Step 2: Add 1.3g of PVP in a mass percentage of 10.8% of the total solution to the green transparent dispersion solution obtained in Step 1, and stir until uniform and transparent to obtain a green transparent liquid to be reacted. The stirring time is 9 hours;

[0020] Step 3: Electrospinning the green transparent liquid to be reacted obtained in Step 2, the distance between the positive and negative poles of electrospinning is 15cm, the electric field is 17kV, and the spinning speed is 0.04mm / min to obtain a light green polymer metal salt Composite fibers were vacuum dried in a vacuum oven at 50°C for 12 hours;

[0021] Step 4: Calcinate the vacuum-dried product of step 3 i...

Embodiment 2

[0024] Step 1: Weigh (NH 4 ) 6 Mo 7 o 24 4H 2 O 0.4943g, Ni(Ac) 2 4H 2 O 0.6967g, citric acid 0.4203g, join in 10ml DMF solvent, ultrasonic vibration 15min, stir to obtain green transparent dispersion solution, the mass percentage that metal salt solute accounts for total solution is 9.6%;

[0025] Step 2: Add 1.3g of PVP in a mass percentage of 10.5% of the total solution to the green transparent dispersion solution obtained in Step 1, and stir until uniform and transparent to obtain a green transparent liquid to be reacted. The stirring time is 10 hours;

[0026] Step 3: Electrospinning the green transparent liquid to be reacted obtained in Step 2. The distance between the positive and negative poles of electrospinning is 20cm, the electric field is 15kV, and the spinning speed is 0.05mm / min to obtain a light green polymer metal salt Composite fibers were vacuum dried in a vacuum oven at 50°C for 12 hours;

[0027] Step 4: Calcinate the vacuum-dried product of step 3 ...

Embodiment 3

[0030] Step 1: Weigh (NH 4 ) 6 Mo 7 o 24 4H 2 O 0.6179g, Ni(Ac) 2 4H 2O 0.8709g, citric acid 0.5254g, join in 10ml DMF solvent, ultrasonic vibration 20min, stir to obtain green transparent dispersion solution, the mass percent of metal salt solute accounting for total solution is 11.7%;

[0031] Step 2: Add 1.3g of PVP in a mass percentage of 10.2% of the total solution to the green transparent dispersion solution obtained in Step 1, and stir until uniform and transparent to obtain a green transparent liquid to be reacted. The stirring time is 11 hours;

[0032] Step 3: Electrospinning the green transparent liquid to be reacted obtained in Step 2. The distance between the positive and negative poles of electrospinning is 20cm, the electric field is 12kV, and the spinning speed is 0.05mm / min to obtain a light green polymer metal salt Composite fibers were vacuum dried in a vacuum oven at 50°C for 12 hours;

[0033] Step 4: Calcinate the vacuum-dried product of step 3 in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com