Automatic reeling machine picking end pot

A mechanism and the technology of thread pot, applied in the field of thread pot, can solve the problem that the needle cannot touch the blind area of work, and achieve the effect of avoiding the blind area of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing example the present invention is described in further detail:

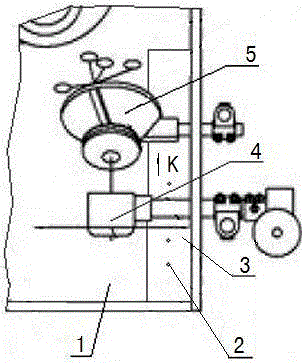

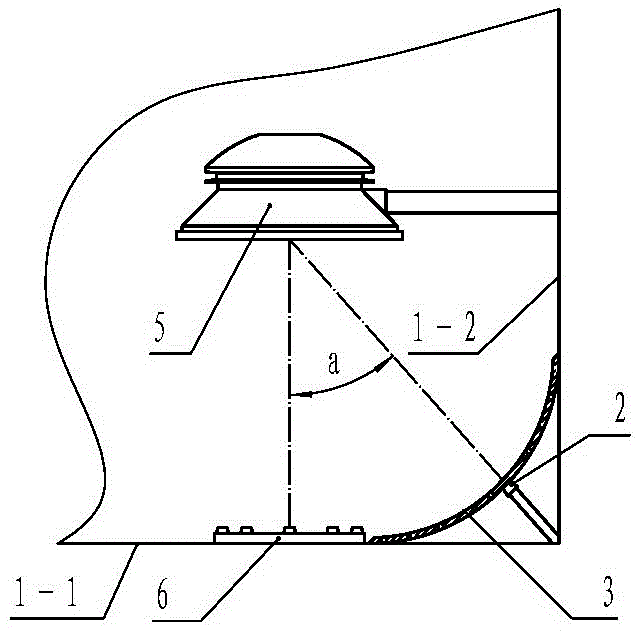

[0010] Such as figure 1 and figure 2 The shown automatic silk reeling machine thread pot includes a pot body 1 with a bottom plate 1-1 and a coaming plate 1-2, an eccentric plate 5 is arranged inside the pot body 1, and a fishing rod is installed near the eccentric plate 5 on the pot body 3. Needle 4, an arc-shaped plate 3 with a plurality of through holes is installed between the bottom plate 1-1 and the surrounding plate 1-2 below the eccentric disc 5 and the needle 4, and an arc-shaped plate 3 is arranged on the arc-shaped plate 3 There are multiple auxiliary sprinkler heads 2, and the axis line of the auxiliary sprinkler head 2 is set at an acute angle a with the axis line of the main sprinkler head; a main sprinkler is arranged on the bottom plate 1-1 below the eccentric disc 5 6. The main sprinkler 6 is provided with a plurality of circumferentially di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com