Electron beam evaporation oblique deposition coating device and application method

An electron beam evaporation and oblique deposition technology, which is applied in vacuum evaporation plating, ion implantation plating, sputtering plating, etc., can solve the problems of manpower and time waste, limited temperature range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

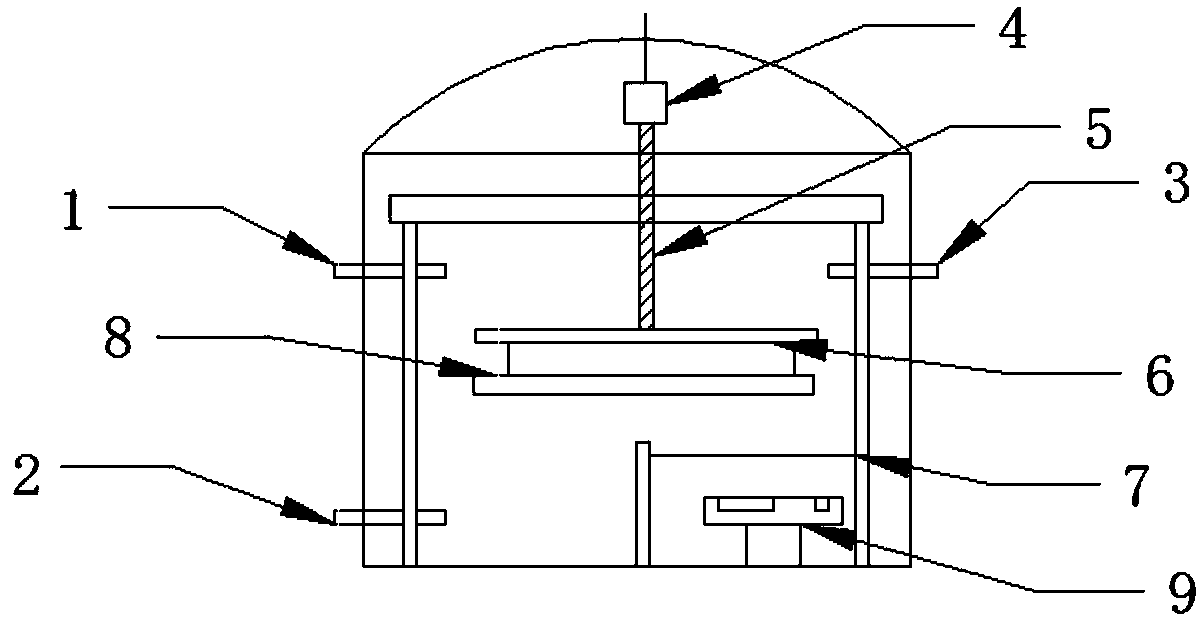

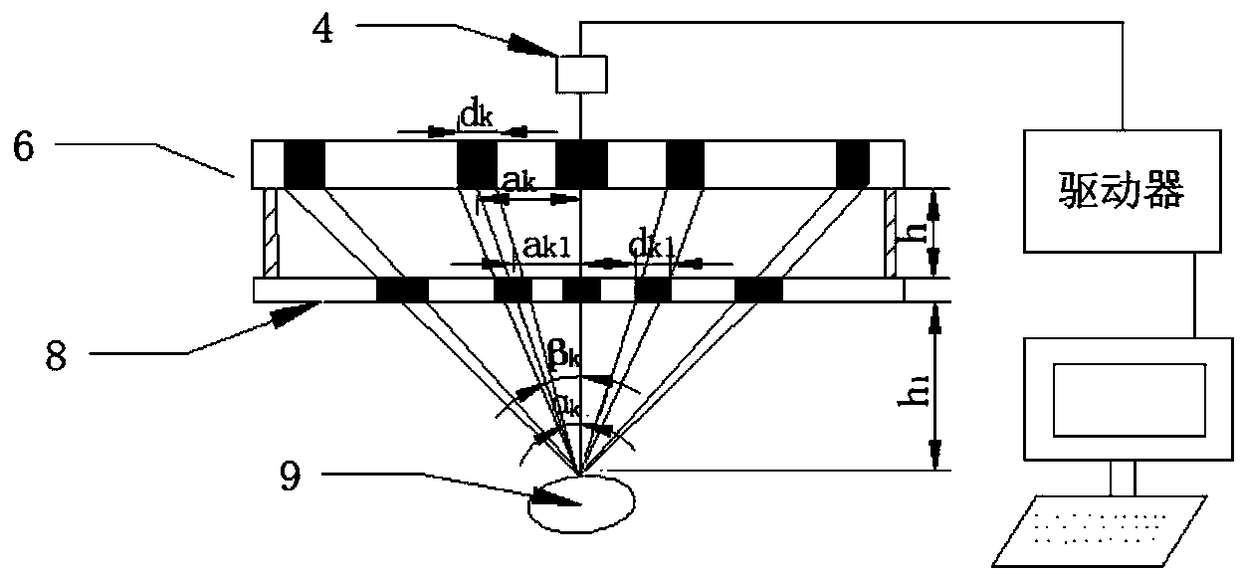

[0047] Please see first figure 1 , figure 2 , as can be seen from the figure, the electron beam evaporation oblique deposition coating device of the present invention includes a vacuum system 1, an air intake device 2, an exhaust valve 3, a stepping motor 4, a connecting cylinder 5, a substrate mounting fixture 6, and a movable baffle 7 , angle collimation device 8 and electron beam evaporation source 9, stepping motor driver and computer, constitute oblique deposition coating device by substrate mounting fixture 6, angle collimation device 8 and connecting stud 10 thereof:

[0048] refer to image 3 , the substrate installation fixture 6 is disc-shaped, from the center to the outer edge of the disc, a first substrate installation circular hole 61, a connecting cylinder connecting screw hole, and a first substrate installation hole 61 are sequentially arranged symmetrically on circles with different diameters. 65. A plurality of second substrate installation holes 62, a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com