Safe pressure reducer

A pressure reducer and safety technology, applied in the direction of pressure vessel, vessel filling method, vessel discharge method, etc., can solve the problems of damage to the pressure reducer device, failure, high pressure of the pressure gauge, etc., to improve the safety performance and prolong the use. effect of age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

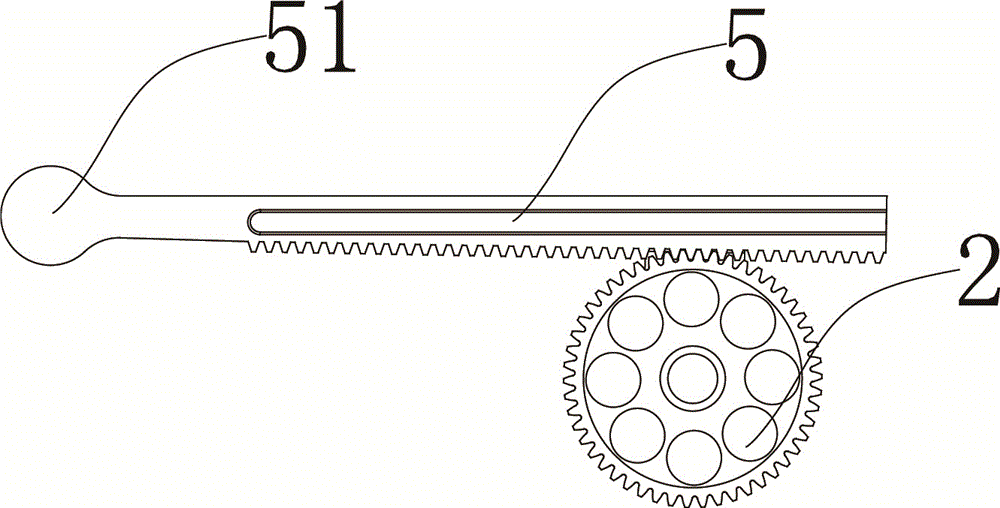

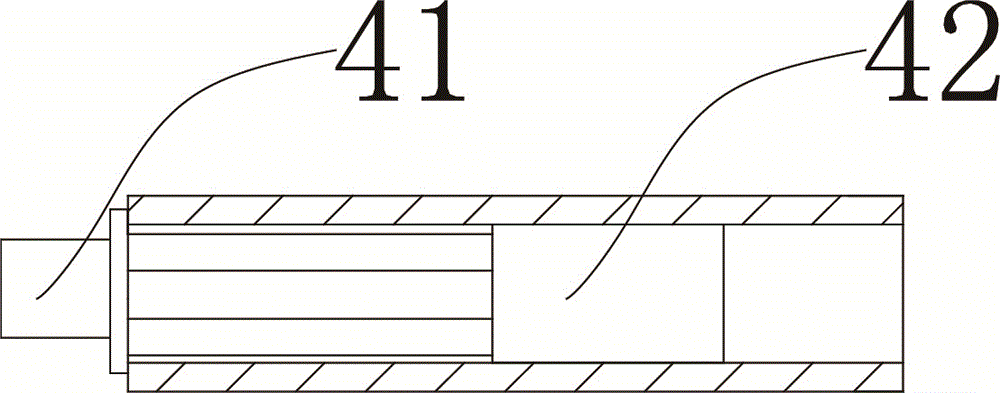

[0020] A safety pressure reducer, comprising a gas cylinder 1, connected to the gas cylinder 1 is a pressure reducer 6, the gas cylinder 1 is provided with an outlet port, and the pressure reducer 6 is provided with an inlet Air interface, the gas cylinder 1 is provided with a handle 3, the bottom of the handle 3 is fixedly connected with a gear 2, and the gear 2 is matched with a rack 5, and the end of the rack 5 is provided with a ball Head 51, the air inlet port of the pressure reducer 6 is provided with a guide rail 4, the guide rail 4 is provided with a column 43, and the end of the column 43 is provided with two universal joint cups and bowls 52, The universal joint cup 52 is wrapped with a ball head 51, and the universal joint cup 52 is provided with an integral shank, and the shank is provided with a threaded hole, and the threaded hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com