Plant callus culture utensil

A technology of callus and culture vessel, which is applied in the direction of tissue cell/virus culture device, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc. Requirements, unfavorable plant callus culture, unstable cover and bottom installation, etc., to achieve the effect of solving the unstable cover and bottom, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

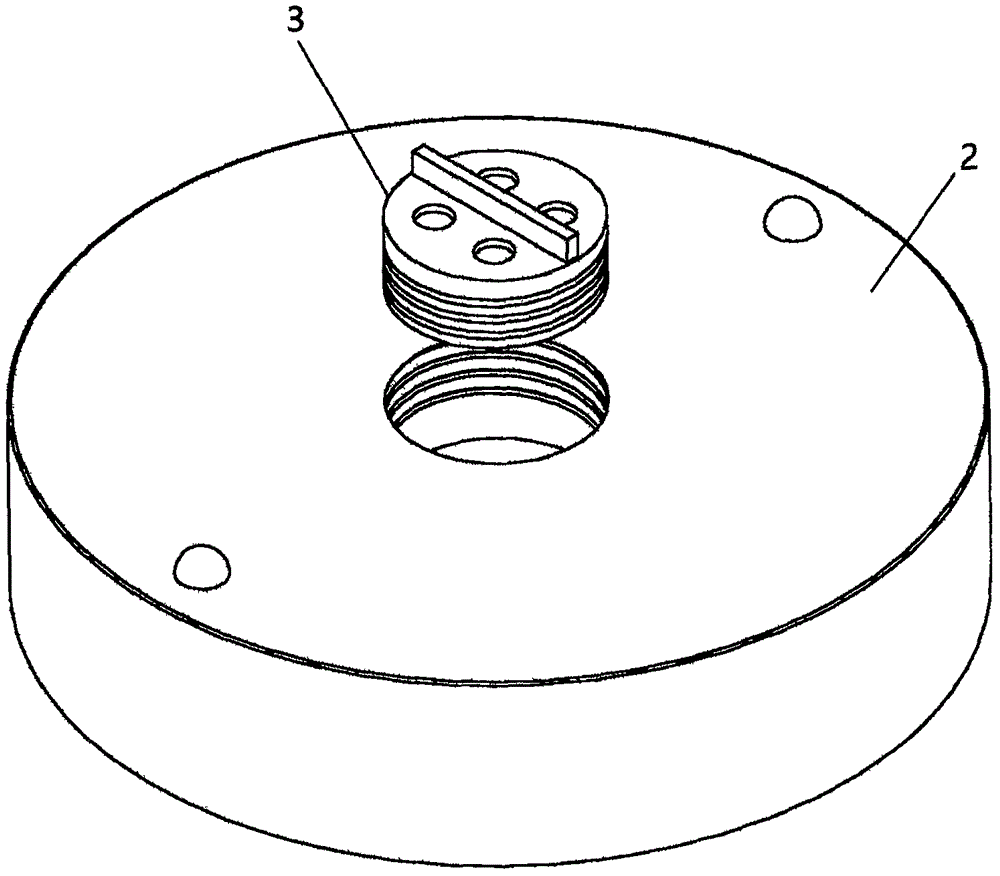

[0020] A plant callus culture vessel, comprising a culture vessel 1 and an upper cover 2, both of which are made of transparent materials. The petri dish 1 is seamlessly connected with the upper cover 2, and a detachable and recyclable connection belt 4 is set between the petri dish 1 and the upper cover 2 to fix it. Two mutually symmetrical The protruding point is provided with a corresponding protruding point at the edge of the upper surface of the upper cover 2 at the same time, and the protruding point is used for the connection belt 4 to carry out snap-type fixed connection of the culture dish 1 and the upper cover 2 . At the same time, a cylindrical ventilation cavity layer 3 is provided at the middle position on the upper surface of the upper cover 2, and the cylindrical ventilation cavity layer 3 includes a cover portion 32 with 2-4 small ventilation holes 34 and a connection with the culture dish. The bottom 31 of the upper cover 2 is injection-molded and provided wit...

Embodiment 2

[0025] A plant callus culture vessel, compared with Example 1, except that the structure of the cylindrical ventilation cavity layer 3 in the upper cover 2 of the culture vessel 1 or the selection of materials are partially changed, the rest are the same as those in Example 1. One said the same. The change is that the connection mode between the cover portion 32 containing the small air holes 34 of the cylindrical ventilation cavity layer 3 and the bottom 31 which is injection-molded with the upper cover 2 of the culture dish and provided with a gas-permeable membrane is different, wherein The material of the selected cover 34 needs to have a certain degree of elasticity. The cover 32 and the bottom 31 are connected by the elasticity of the material itself in a manner similar to snap buttons, and an inner concave point 36 is set at about half the height of the cover 32 as a fixed point. And the diameter of its cover 32 needs to be slightly greater than the diameter of the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com