Biodegradable silent packing tape and preparation method thereof

A biodegradable, tape technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of environmental pollution, large tearing sound of tapes, and few components, so as to eliminate environmental pollution and avoid noise pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

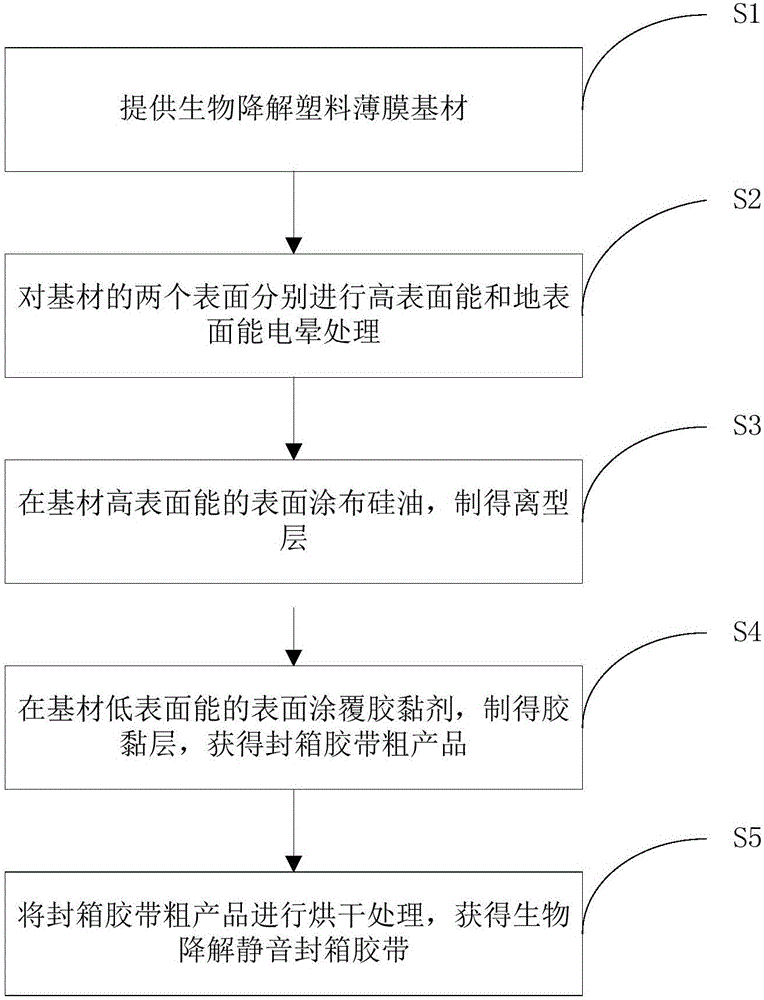

[0023] The preparation process of the above-mentioned biodegradable silent sealing tape, such as figure 2 shown, including the following steps:

[0024] S1. Provide a biodegradable plastic film and make it into a strip-shaped substrate.

[0025] In this step, the biodegradable plastic film made from one or more raw materials of starch, cellulose and chitin is selected, and the specific preparation process is as follows:

[0026] First, starch, cellulose, chitin and other raw materials are fermented to produce lactic acid, and then the lactic acid is converted into polylactic acid plastic granules (PLA granules) through chemical synthesis; secondly, the PLA granules are fed into the extruder and processed at 140 Under the action of ~160℃ and screw shearing, melt and plasticize, extrude and then filter to remove impurities; secondly, put the plasticized polylactic acid into the T-shaped die to form a sheet material, which is cooled Then, it is preheated by the longitudinal st...

Embodiment 1

[0041] A preparation process of a biodegradable silent sealing tape ring:

[0042] S1. First, 50 kg of starch is fermented to make lactic acid, and then the lactic acid is converted into PLA particles through chemical synthesis; secondly, the PLA particles are fed into the extruder, and melted at 150°C and under the action of screw shear. After plasticizing and extruding, filter to remove impurities; secondly, put the plasticized polylactic acid into the T-shaped die to form a sheet material, and the sheet material is cooled and then preheated by a longitudinal stretching machine for longitudinal stretching ; Finally, it is sent to a horizontal drawing machine for transverse stretching to obtain a biodegradable plastic film.

[0043] S2. Corona treatment is carried out on the two surfaces of the biodegradable plastic film substrate respectively, and the surface energy of the outer surface to be coated with silicone oil is controlled to be 52 dyne; for the other surface, the su...

Embodiment 2

[0051] A preparation process of a biodegradable silent sealing tape ring:

[0052]S1. Ferment 30 kg of cellulose and 20 kg of chitin to produce lactic acid, and then convert the lactic acid into PLA particles through chemical synthesis; secondly, feed the PLA particles into the extruder and heat them at 160°C and under the shearing conditions of the screw. Under the action, it melts, plasticizes, extrudes, and then filters to remove impurities; secondly, the plasticized polylactic acid enters the T-shaped die to form a sheet material, which is cooled and then preheated by a longitudinal stretching machine Longitudinal stretching is carried out; finally, it is sent to a horizontal stretching machine for transverse stretching to obtain a biodegradable plastic film.

[0053] S2. Corona treatment is performed on the two surfaces of the biodegradable plastic film base material respectively, and the surface energy of the outer surface to be coated with silicone oil is controlled to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com