Interior plastic plate of automotive door and preparation method of interior plastic plate

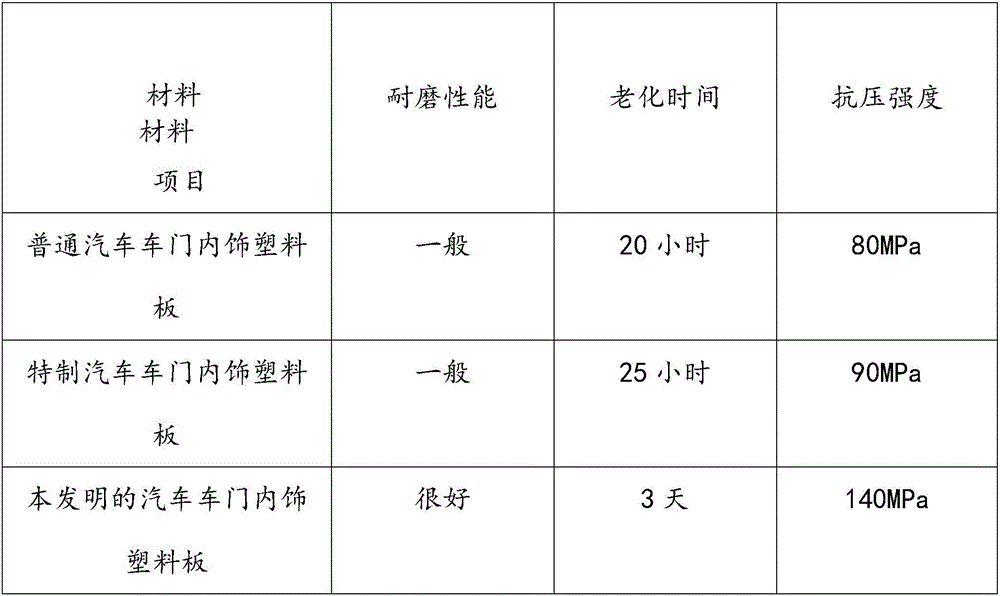

A technology for automobile doors and plastic panels, applied in the field of automotive door interior plastic panels and its preparation, can solve the problems of no anti-aging effect, poor wear resistance, low structural strength, etc., and achieve good molding effect and stable structure High performance and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A plastic panel for automobile door interiors, made of the following materials in parts by weight, including 28 parts of aromatic polycarbonate, 16 parts of jasmonal, 2 parts of sodium carbonate, 11 parts of cuprous chloride, and trichloro 12 parts of iron oxide, 16 parts of methylaluminoxane, 22 parts of boric acid alkyl alcohol amide, 35 parts of butyl hydroxyanisole, 7 parts of zinc stearate, 16 parts of tert-butyl peroxybenzoate, 9 parts of emery, 8 parts of zirconocene dichloride, 5 parts of polyvinylpyrrolidone, 16 parts of calcium stearate, 6 parts of pentaerythritol, 13 parts of ethoxyquinoline, 20 parts of polyacrylonitrile-based carbon fiber, 3 parts of benzoyl oxide, 11 parts of polyvinyl formal and 10 parts of diisononyl phthalate.

[0019] A method for preparing a plastic panel for automobile door interior trim includes the following steps:

[0020] 1) Combine 28 parts of aromatic polycarbonate, 16 parts of piperonal, 2 parts of sodium carbonate, 11 parts of cu...

Embodiment 2

[0026] A plastic panel for automobile door interiors, made of the following materials in parts by weight, including 29 parts by weight of aromatic polycarbonate, 18 parts by jasmonal, 3 parts by sodium carbonate, 13 parts by cuprous chloride, and trichloride 13 parts of iron oxide, 18 parts of methylaluminoxane, 23 parts of boric acid alkyl alcohol amide, 37.5 parts of butyl hydroxyanisole, 9 parts of zinc stearate, 22 parts of tert-butyl peroxybenzoate, 10.5 parts of emery, 10 parts of zirconocene dichloride, 7.5 parts of polyvinylpyrrolidone, 18 parts of calcium stearate, 7.5 parts of pentaerythritol, 13.5 parts of ethoxyquinoline, 22.5 parts of polyacrylonitrile-based carbon fiber, 5.5 parts of benzoyl oxide, 12 parts of polyvinyl formal and 11.5 parts of diisononyl phthalate.

[0027] A method for preparing a plastic panel for automobile door interior trim includes the following steps:

[0028] 1) Combine 29 parts of aromatic polycarbonate, 18 parts of piperonal, 3 parts of so...

Embodiment 3

[0034] A plastic panel for automobile door interior trim, which is made of the following materials in parts by weight, including 30 parts of aromatic polycarbonate, 20 parts of jasmonal, 4 parts of sodium carbonate, 15 parts of cuprous chloride, and trichloride 14 parts of iron oxide, 20 parts of methylaluminoxane, 24 parts of boric acid alkyl alcohol amide, 40 parts of butyl hydroxyanisole, 11 parts of zinc stearate, 28 parts of tert-butyl peroxybenzoate, 11 parts of carborundum, 12 parts of zirconocene dichloride, 10 parts of polyvinylpyrrolidone, 20 parts of calcium stearate, 9 parts of pentaerythritol, 14 parts of ethoxyquinoline, 25 parts of polyacrylonitrile-based carbon fiber, 8 parts of benzoyl oxide, 13 parts of polyvinyl formal and 13 parts of diisononyl phthalate.

[0035] A method for preparing a plastic panel for automobile door interior trim includes the following steps:

[0036] 1) Combine 30 parts of aromatic polycarbonate, 20 parts of piperonal, 4 parts of sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com