A kind of compound applied in OLED field and its preparation method and application

A compound and technology in the field, applied in chemical instruments and methods, organic chemistry, semiconductor/solid-state device manufacturing, etc., can solve the problems of slow reaction rate, insufficient display screen, and narrow viewing angle of TFT-LCD display, and achieve good performance. , fast response rate, the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

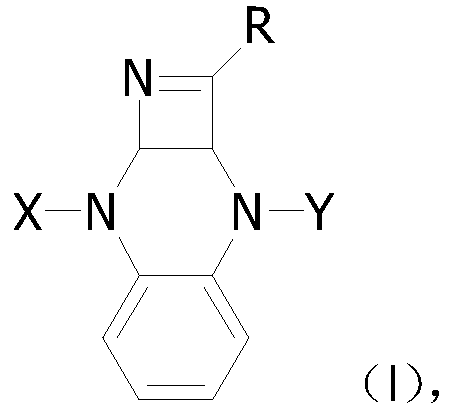

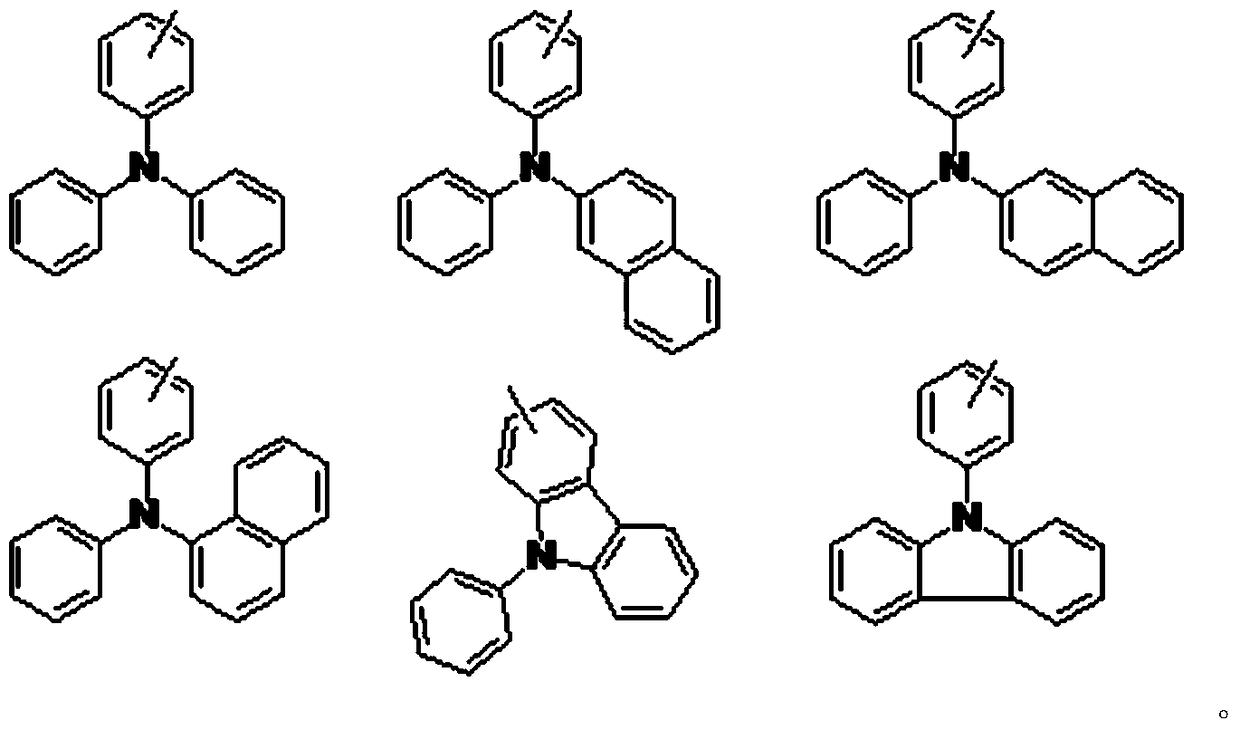

[0033] A preparation method of the above-mentioned compound, its process synthesis route is:

[0034]

[0035] A material applied in the field of OLED, the material includes the compound mentioned above.

[0036] A hole-transporting layer material, a light-emitting layer material, and an electron-transporting layer material containing the above-mentioned compound, preferably, a blue-light, green-light, and red-light host material containing the above-mentioned compound.

[0037] An OLED device comprising the compound described above.

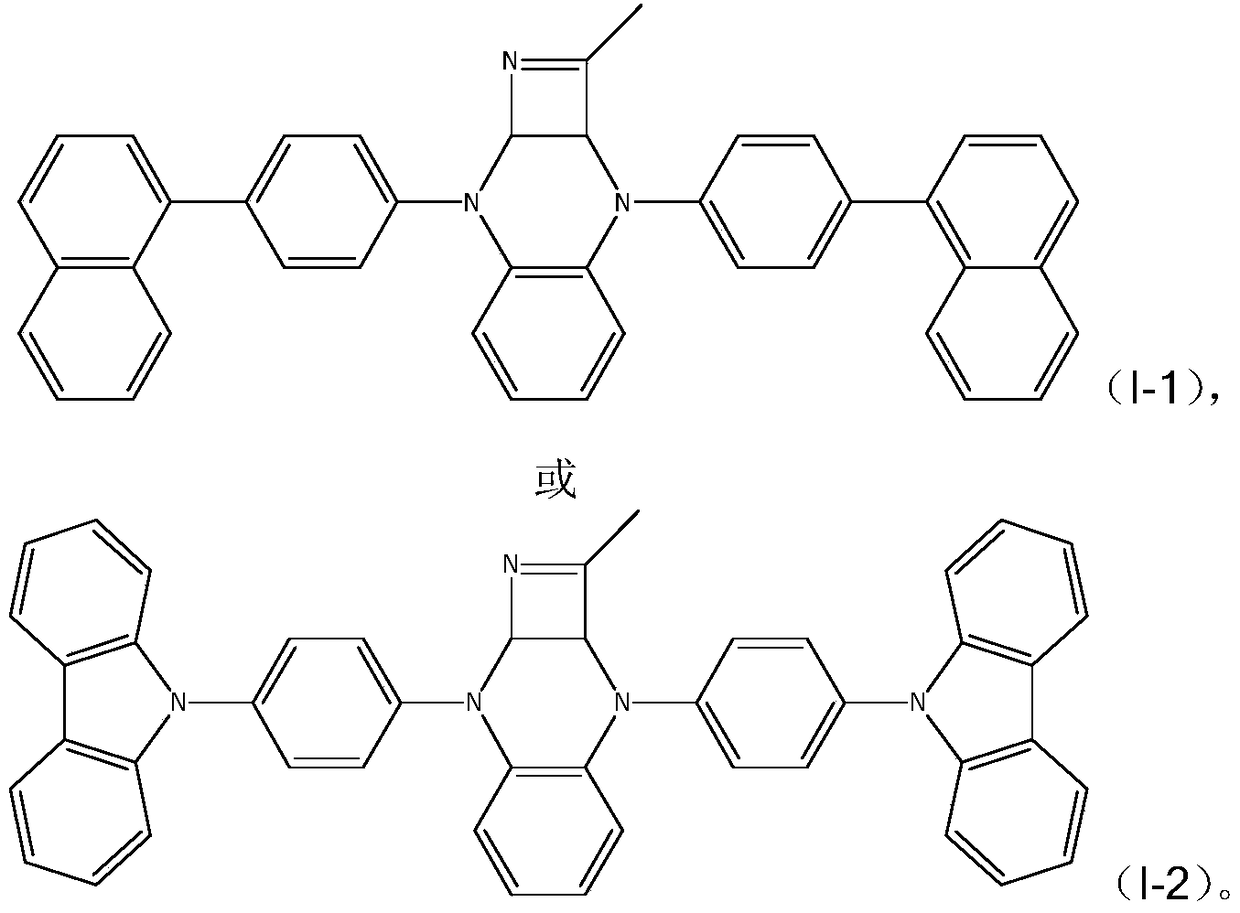

[0038] The above-mentioned technical scheme and its beneficial effects are further explained and illustrated below by taking the compounds represented by structures (I-1) and (I-2) as examples.

Embodiment 1

[0040] 1. A compound (I-1) applied in the OLED field:

[0041]

[0042] 2. The preparation method of compound (I-1)

[0043] (1) Process synthesis route

[0044]

[0045] (2) Concrete preparation steps:

[0046] Step 1: add 0.1mol compound (1), 0.2mmol NBS and 1000mL THF to the reaction flask, react at room temperature under nitrogen protection for 24 hours, remove THF, add dichloromethane, wash with water, dry, pass the crude product through the column, and then The product compound (2) was obtained by recrystallization and purification with dichloromethane and ethanol, with a yield of 43%, C4H5Br2N, M=226.90, and M+1=228.2 was detected;

[0047] Step 2: 0.1mol compound (2), 0.1mmol compound (3), 1000mL acetone and 0.2mol potassium carbonate, react at 60°C under nitrogen protection for 24 hours, cool down to room temperature, remove acetone, add dichloromethane, wash with water , dried, the crude product was passed through the column, and then recrystallized and puri...

Embodiment 2

[0050] 1. A compound (I-2) used in the OLED field:

[0051]

[0052] 2, the preparation method of compound (I-2)

[0053] (1) Process synthesis route

[0054]

[0055] (2) Concrete preparation steps:

[0056]Step 1: add 0.1mol compound (1), 0.2mmol NBS and 1000mL THF to the reaction flask, react at room temperature under nitrogen protection for 24 hours, remove THF, add dichloromethane, wash with water, dry, pass the crude product through the column, and then The product compound (2) was obtained by recrystallization and purification with dichloromethane and ethanol, with a yield of 43%, C4H5Br2N, M=226.90, and M+1=228.2 was detected;

[0057] Step 2: 0.1mol compound (2), 0.1mmol compound (3), 1000mL acetone and 0.2mol potassium carbonate, react at 60°C under nitrogen protection for 24 hours, cool down to room temperature, remove acetone, add dichloromethane, wash with water , dried, the crude product was passed through the column, and then recrystallized and purified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com