Compost fermentation tank

A fermentation tank and composting technology, applied in the field of composting fermentation tanks, can solve the problems of inaccurate measurement data, inability to achieve real-time measurement, and poor representativeness of detected gas, so as to avoid clogging of pores, facilitate transportation and transfer, and have small concentration changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

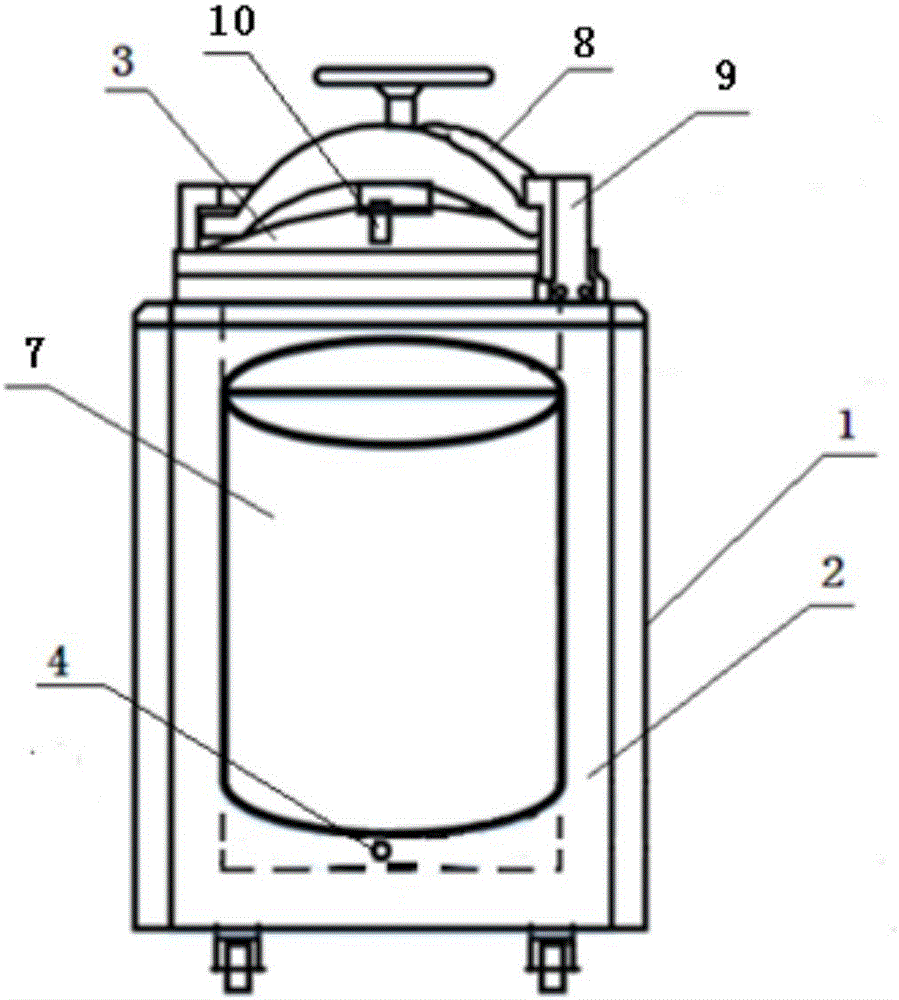

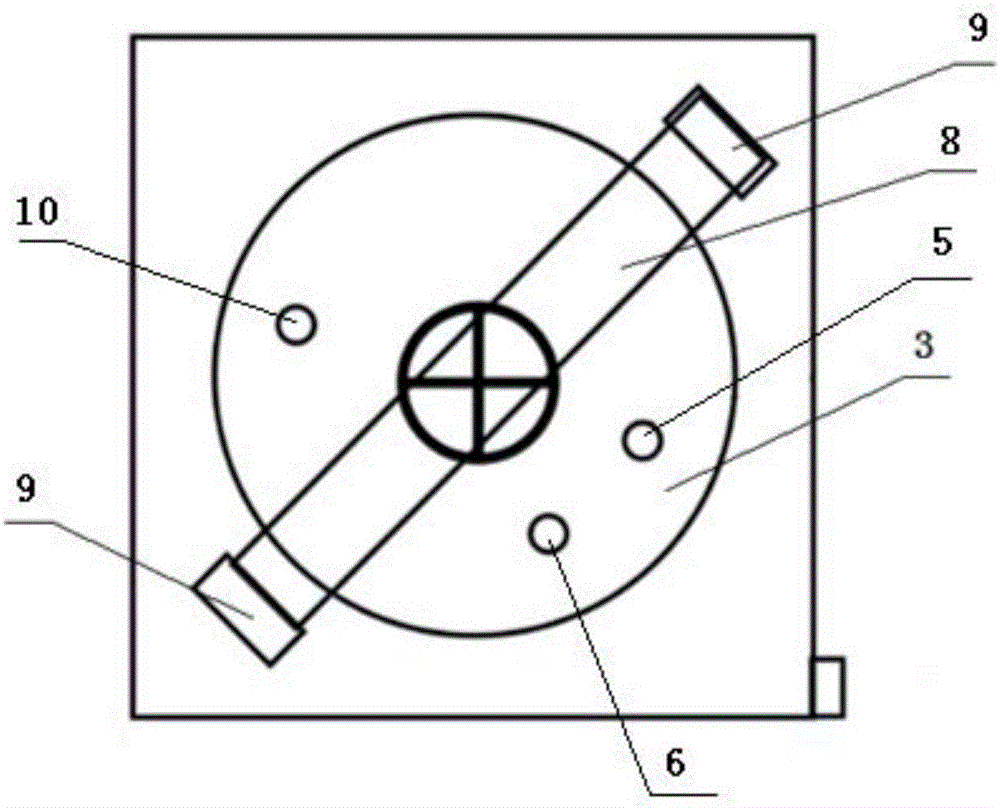

[0022] like figure 1 , image 3 As shown, the present invention provides a compost fermenter, which includes an outer tank body 1 and an inner tank body 2 built in the outer tank body 1 . Heat insulating material is filled between the outer tank body 1 and the inner tank body 2 . The top of the outer tank body 1 is connected with a top cover 3 , and the top cover 3 is connected with a gas collection pipeline 5 and an emptying pipeline 6 . An air delivery device 4 is placed on the bottom of the inner tank body 2 , and the input end of the air delivery device 4 passes through the inner tank body 2 and the outer tank body 1 .

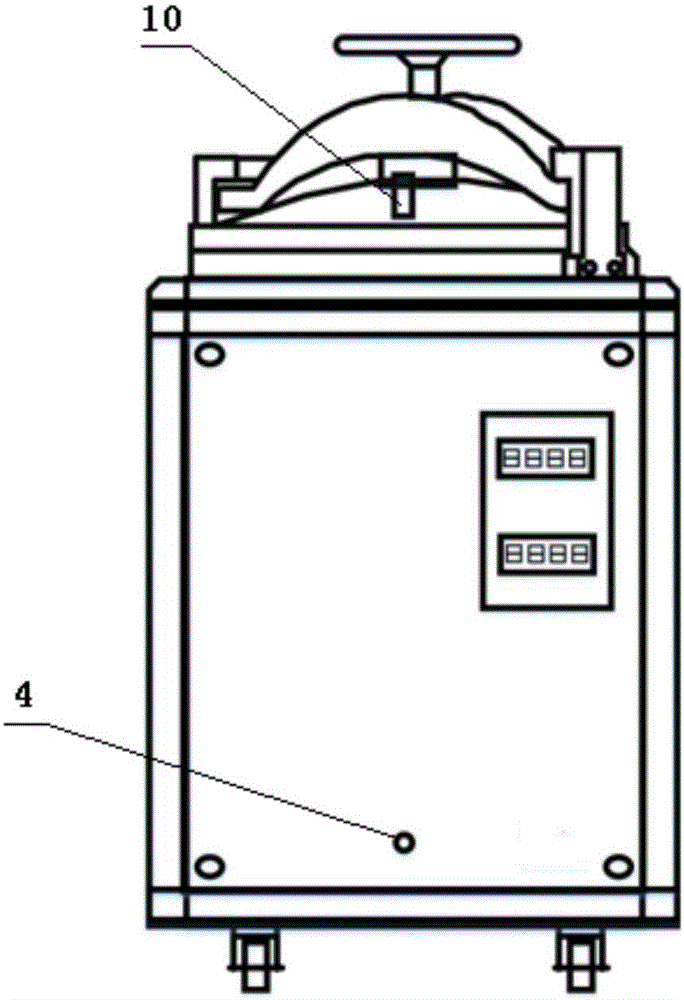

[0023] Further, as figure 1 , figure 2 As shown, the outer tank body 1 is a cuboid structure with a circular opening on the top, the inner tank body 2 is a cylindrical structure without a cover, and the top cover 3 is a circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com