Filling paste slurry suitable for tunnel construction goaf

A technology for tunnel construction and filling paste, which is applied in the field of grouting for underground engineering treatment, can solve the problems that the grouting effect is greatly affected by the construction level, the early strength of cement fly ash slurry is low, and the slurry filling process is complicated, and the setting time is reached. Controllable, satisfying filling processing requirements, and convenient and quick preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

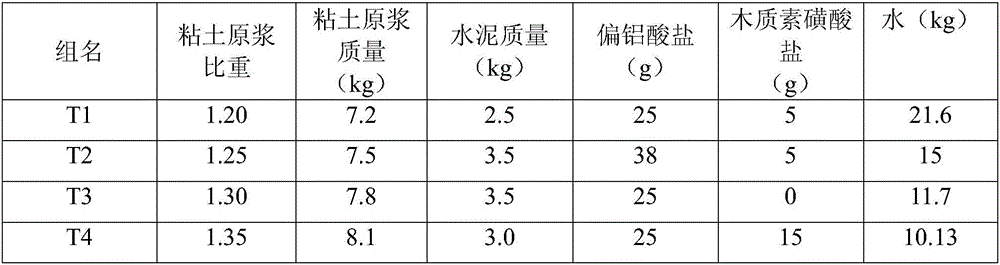

Embodiment 1

[0028] The present invention is applicable to an embodiment of the filling slurry for tunnel construction gobs, and the filling slurry is mainly prepared from clay raw slurry, cement and water. Among them, the original clay and water are used to make clay pulp with a clay pulper, the specific gravity of the clay pulp is 1.20, the quality of the clay pulp is 7.2kg, the plasticity index of the clay is not less than 14, and the particle size of the clay is less than 0.005mm The number of cosmids is not less than 30%. The cement is ordinary Portland cement 42.5, the sieve residue of the cement after passing through the 80μm square hole sieve is not more than 5%, the quality of the cement is 2.5kg, and the mass ratio of clay stock to cement is 2.88:1. The amount of water added was 21.6 kg. Also be added with modifying agent in this filling paste, this modifying agent comprises quick-setting agent sodium metaaluminate and water-reducing agent calcium lignosulfonate, wherein, the in...

Embodiment 2

[0031] The present invention is applicable to an embodiment of the filling slurry for tunnel construction gobs, and the filling slurry is mainly prepared from clay raw slurry, cement and water. Among them, the original clay and water are used to make clay pulp with a clay pulper, the specific gravity of the clay pulp is 1.25, the quality of the clay pulp is 7.5kg, the plasticity index of the clay is not less than 14, and the particle size of the clay is less than 0.005mm The number of cosmids is not less than 30%. The cement is ordinary Portland cement 42.5, the sieve residue of the cement after passing through the 80μm square hole sieve is not more than 5%, the quality of the cement is 3.5kg, and the mass ratio of clay slurry to cement is 2.14:1. The addition amount of water is 15kg. Also be added with modifying agent in this filling paste, this modifying agent comprises quick-setting agent sodium metaaluminate and water reducer calcium lignosulfonate, wherein, the mixing am...

Embodiment 3

[0034] The present invention is applicable to an embodiment of the filling slurry for tunnel construction gobs, and the filling slurry is mainly prepared from clay raw slurry, cement and water. Among them, the original clay and water are used to make clay pulp with a clay pulper, the specific gravity of the clay pulp is 1.30, the quality of the clay pulp is 7.8kg, the plasticity index of the clay is not less than 14, and the particle size of the clay is less than 0.005mm The number of cosmids is not less than 30%. The cement is ordinary Portland cement 42.5, the sieve residue of the cement after passing through the 80μm square hole sieve is not more than 5%, the quality of the cement is 3.5kg, and the mass ratio of clay slurry to cement is 2.22:1. The amount of water added was 11.7 kg. Also be added with modifying agent in this filling paste, this modifying agent comprises quick-setting agent sodium metaaluminate and water reducer calcium lignosulfonate, wherein, the mixing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com