Linkage clamp

A linkage and link technology, applied in the field of linkage clips, can solve the problems of limited opening and closing, small application range, and stiff operation, and achieve the effects of saving costs, simplifying the operation process, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

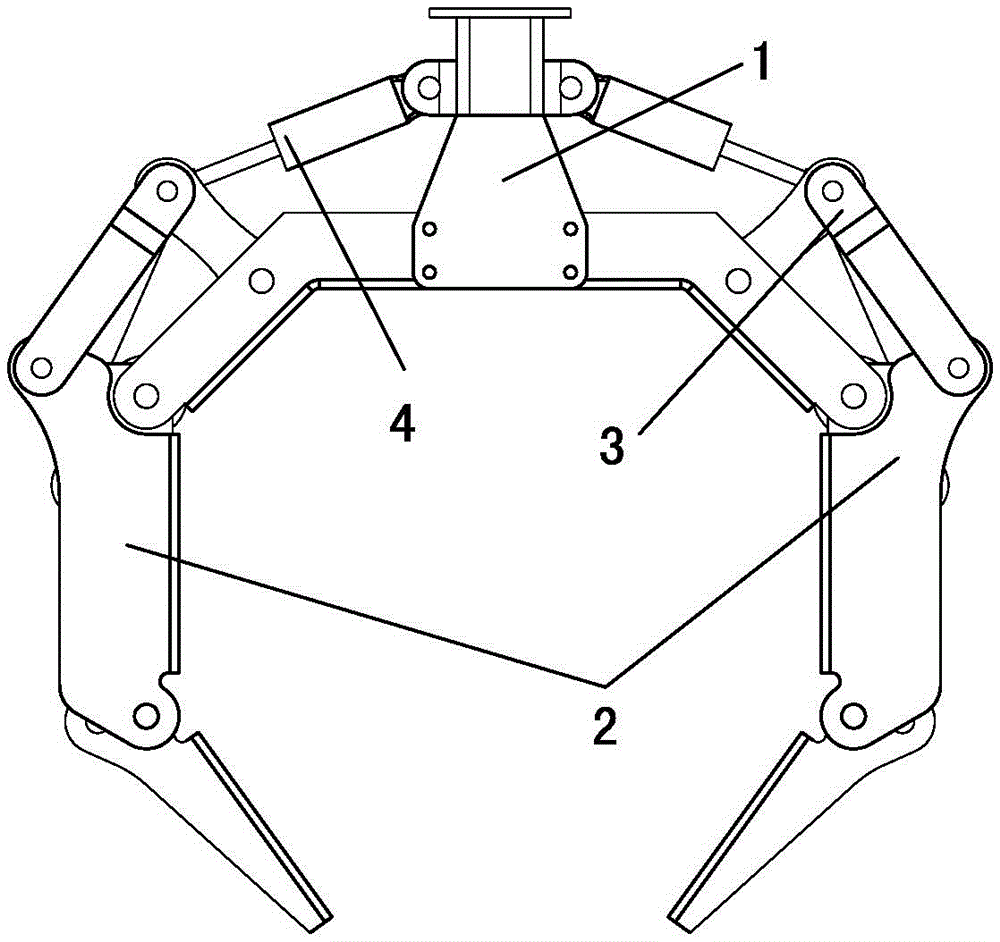

[0024] Such as Figure 1-6 As shown, the interlocking clamp of the present invention includes a connecting base 1 and two clamping parts 2 respectively installed on the left and right sides of the lower part of the connecting base 1, and a control structure 3 and a telescopic device 4 for controlling the opening and closing of the two clamping parts.

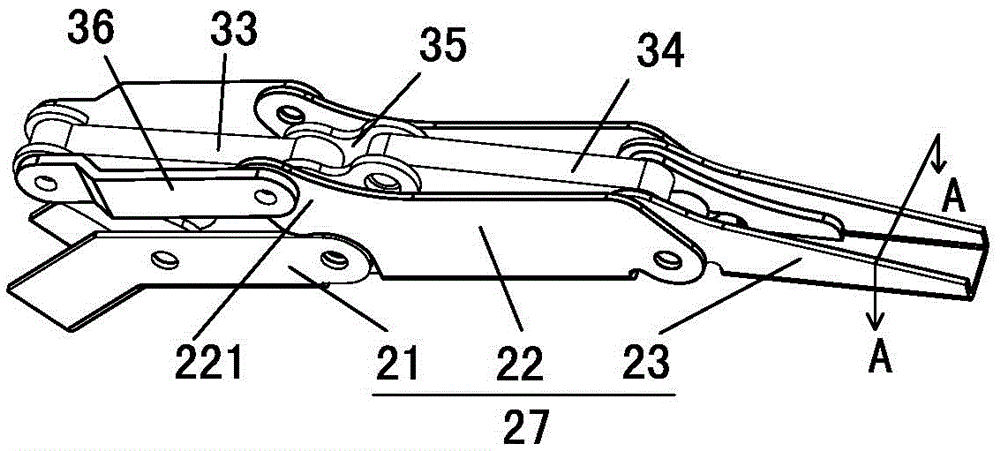

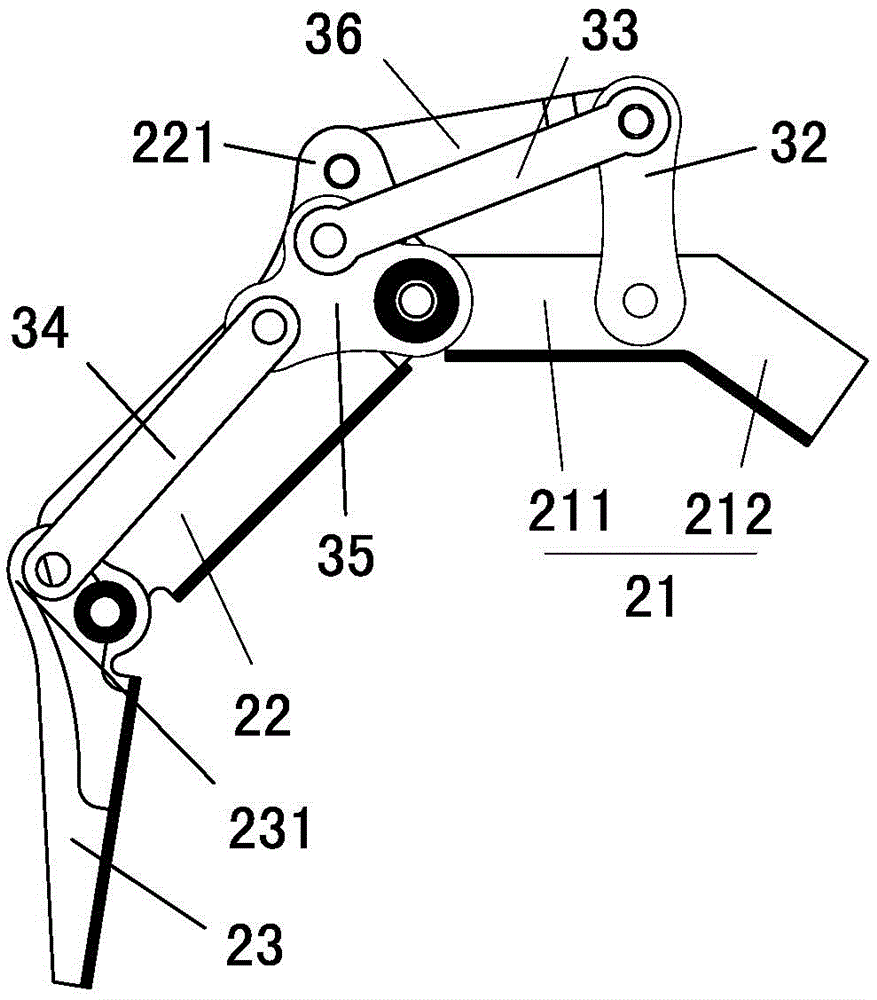

[0025] The clip part 2 includes an inner arm part 21 , a middle arm part 22 and a tail arm part 23 which are hinged to each other in turn. The multi-section parts (inner arm part 21, middle arm part 22 and tail arm part 23) are articulated and combined, so that the clip part 2 can be straightened and opened to clamp more or larger diameter objects. The inner sides of the middle arm portion 22 and the tail arm portion 23 are respectively provided with a middle ear piece 221 and a tail ear piece 231 protruding upward. The inner arm portion 21, the middle arm portion 22 and the outer arm portion 23 respectively comprise a base pla...

Embodiment 2

[0029] Such as Figure 1-Figure 7 As shown, based on Embodiment 1, the number of clamping arms 28 of the two clamping parts 2 is the same. According to requirements, the clamping arms 28 of the two clamping parts 2 can be arranged alternately (not shown), and can also be arranged one by one correspondingly. For example, each clamping part 2 has a clamping arm 28 (such as Figure 6 shown).

Embodiment 3

[0031] Such as Figure 1-5 , Figure 7 As shown, based on Embodiment 1, the number of clamping arms 28 of the two clamping parts 2 differs by one, and the clamping arms 28 of the two clamping parts 2 are arranged alternately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com