Bearing ring feeder

A bearing ring and feeder technology, which is applied to conveyor objects, transportation and packaging, etc., can solve problems such as increased production costs, waste of raw materials, product bumps, etc., to improve work efficiency, reduce production costs, and avoid mutual collisions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

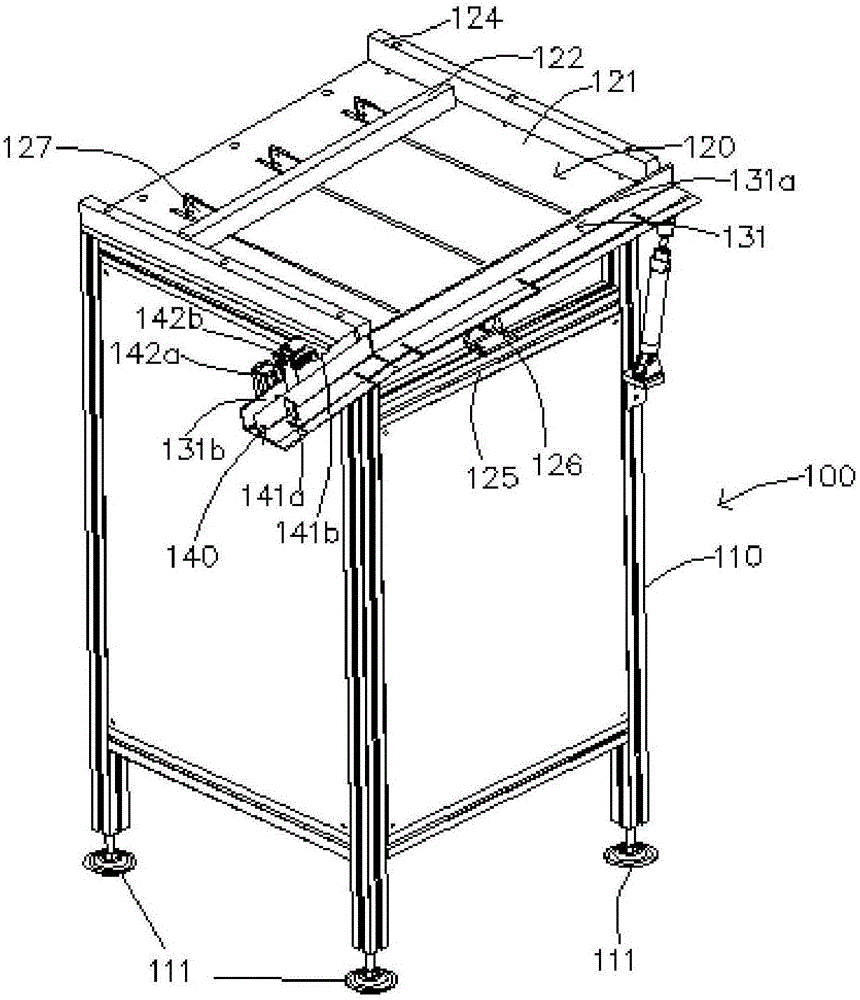

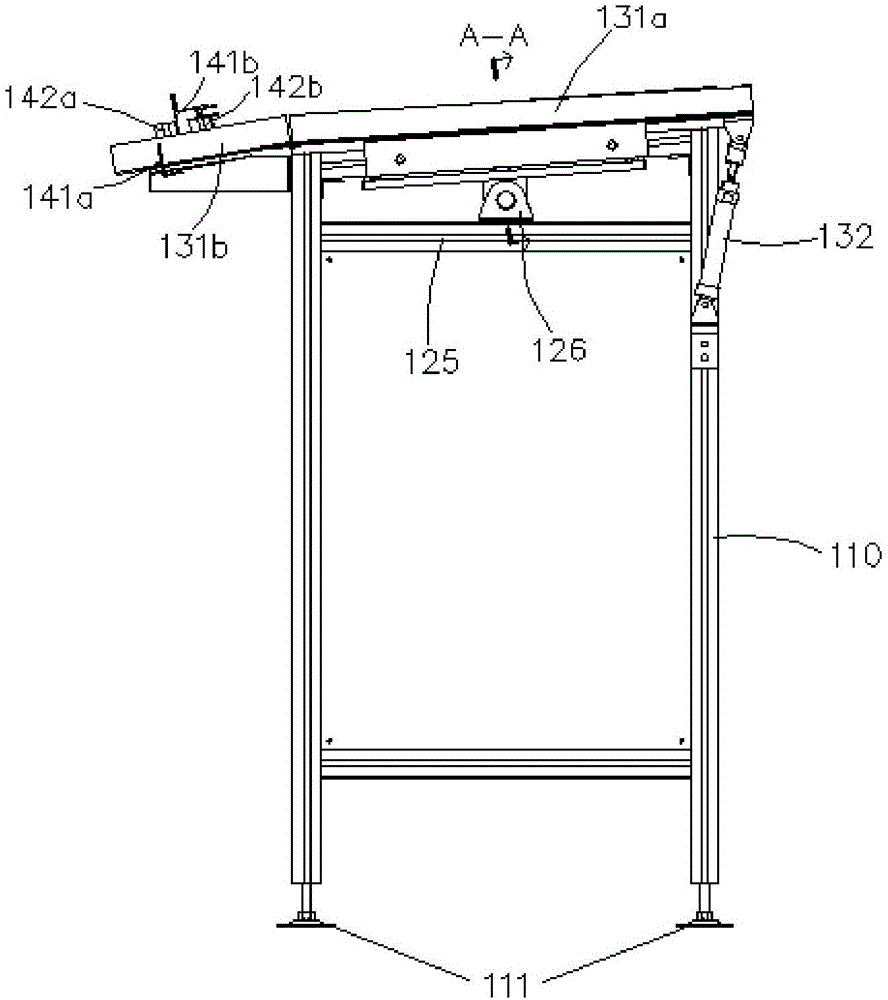

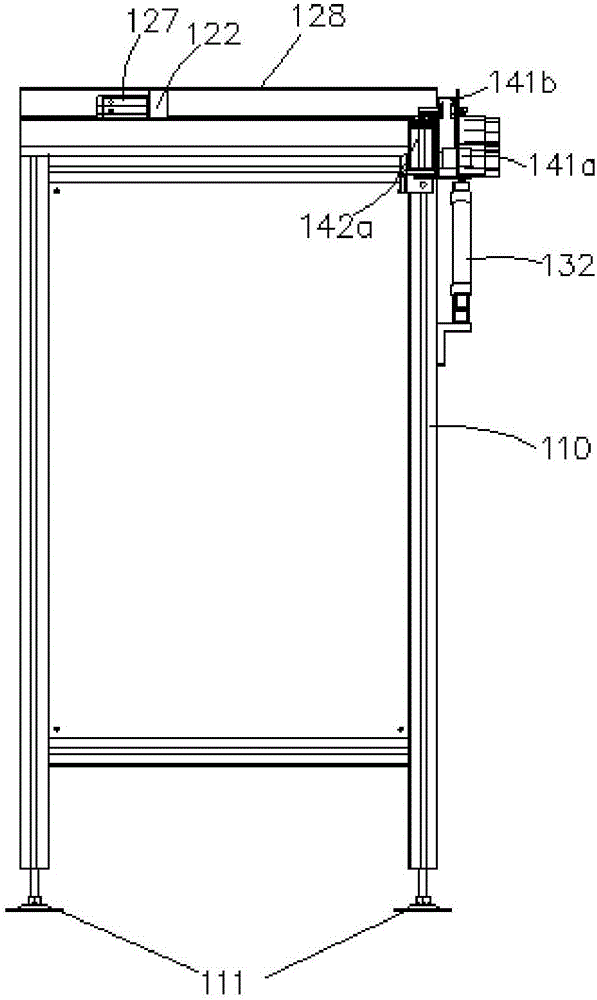

[0017] see Figure 1 to Figure 4 , shown in the figure is a bearing ring feeder 100 , including a frame 110 , a pushing device 120 , a conveying device 130 and a ring dividing device 140 . The base of the frame 110 is provided with four circular spikes 111; the conveying device 130 is arranged on one side of the frame 110, including a feeding channel 131, which can be divided into a feeding channel 131a on the frame 110 And protruding from the frame 110 portion of the sub-circle blanking channel 131b, the lowest end of the conveying blanking channel 131a can be hinged on the frame 110.

[0018] The higher end of the conveying and unloading channel 131a is provided with a push rod device that drives the inclination of the unloading channel 131. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com