Accumulation type semi-automatic multilayer garbage storage bin and method for applying same

A semi-automatic, accumulative-type technology, applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of unsatisfactory and unsatisfactory tourist attractions, and achieve the effects of low time efficiency, improved work efficiency, and increased economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

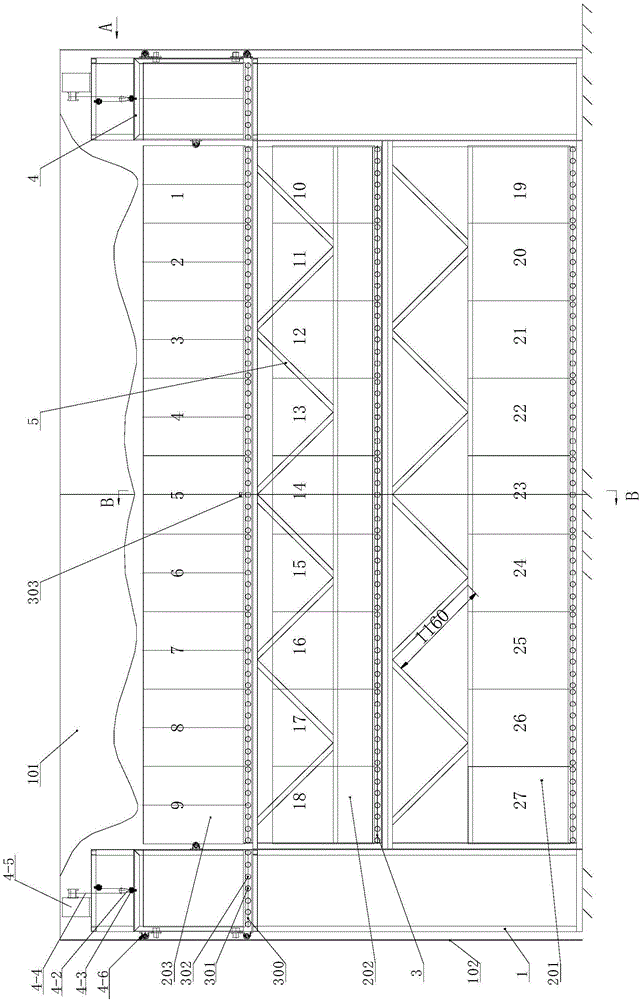

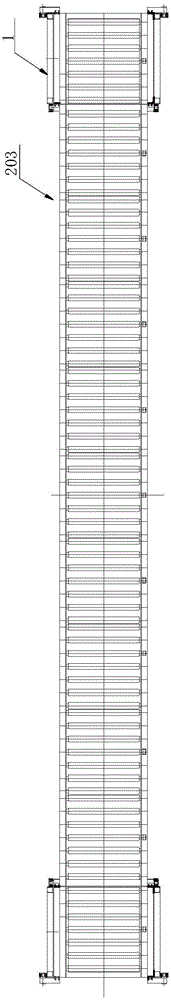

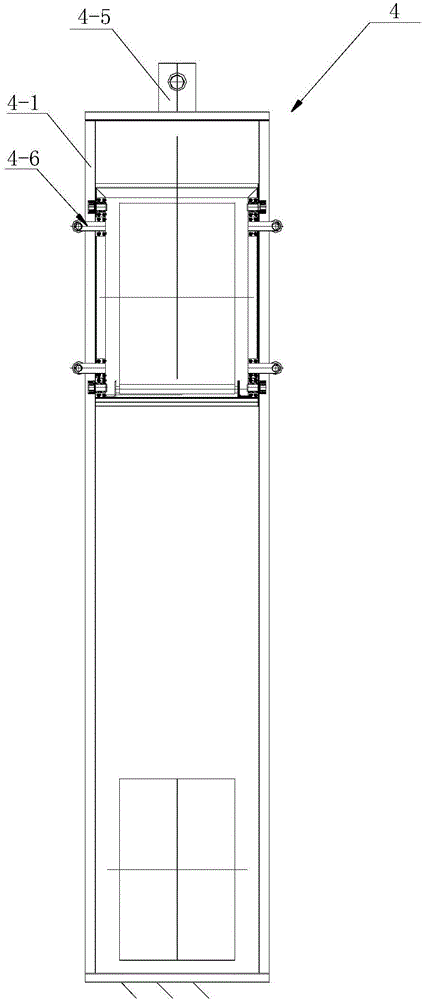

[0046] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0047] see Figure 1 to Figure 5 , an accumulative semi-automatic multi-storey garbage storage bin, characterized in that: it includes a main support frame 1 arranged mirror-image symmetrically on both sides, a shell 101 is arranged around the main support frame; a sealed door 102 is arranged on one side of the main support frame , the shell can also be sprayed with the style of the scenic spot, echoing with the scenic spot, without damaging the beauty of the scenic spot; along the height direction, the main support frame is equipped with three layers of trash can transfer space, which are respectively the first layer of transfer space 201 and the second layer of transfer space 202. The transfer space 203 on the third floor, each transfer spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com