High-efficiency ship cabin enclosure bulkhead board

A technology for coaming panels and ships, which is applied to hull bulkheads, hull panels, hulls, etc. It can solve problems such as abrupt components and affecting layout, and achieve the effects of avoiding resonance, convenient construction and maintenance, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

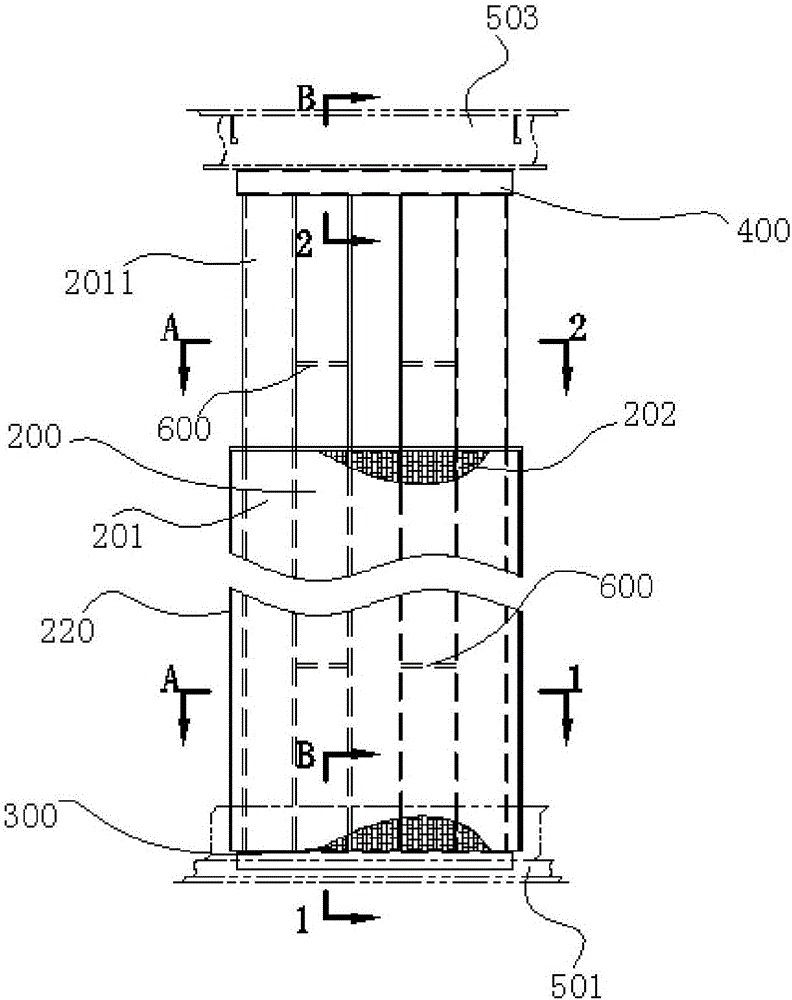

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

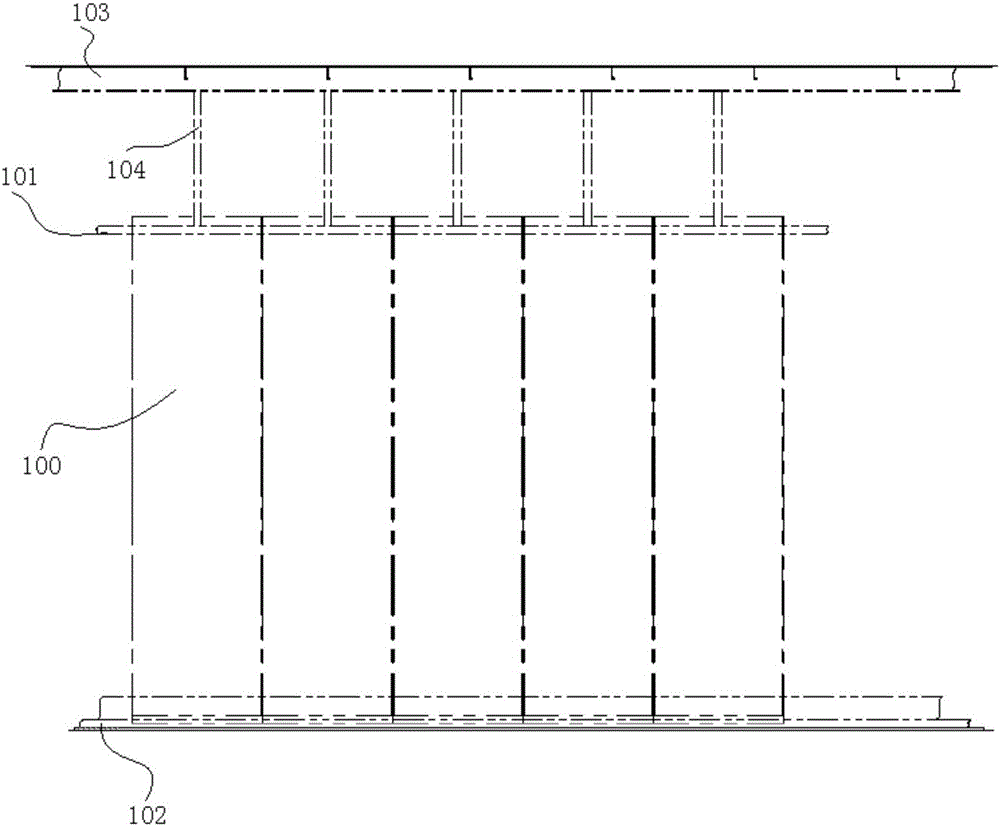

[0033] see Figure 2 to Figure 6 , the high-efficiency ship cabin wall panel provided by the present invention includes the wall panel 200 .

[0034] The bottom end of the wall panel 200 is detachably fixed on the bottom deck 501 of the ship cabin through the first connecting piece 300 , and its top end is in contact with the ceiling 502 of the ship cabin.

[0035] The wall panel 200 extends upwards with a connecting end 210 , the connecting end 210 can pass through the ceiling 502 and is fixedly connected with the top deck 503 of the cabin of the ship through the second connecting piece 400 .

[0036] Connecting joints 220 are provided on both sides of the surrounding wall panel 200 respectively, and the surrounding wall panel 200 can be seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com