Locomotive and locomotive collision-proof structure for rail vehicle

A rail vehicle and anti-collision technology, applied in the field of rail transit, can solve the problems of injury to drivers and passengers, occupying a large space, no protection, etc., and achieve the effects of improving safety performance, strong anti-collision ability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

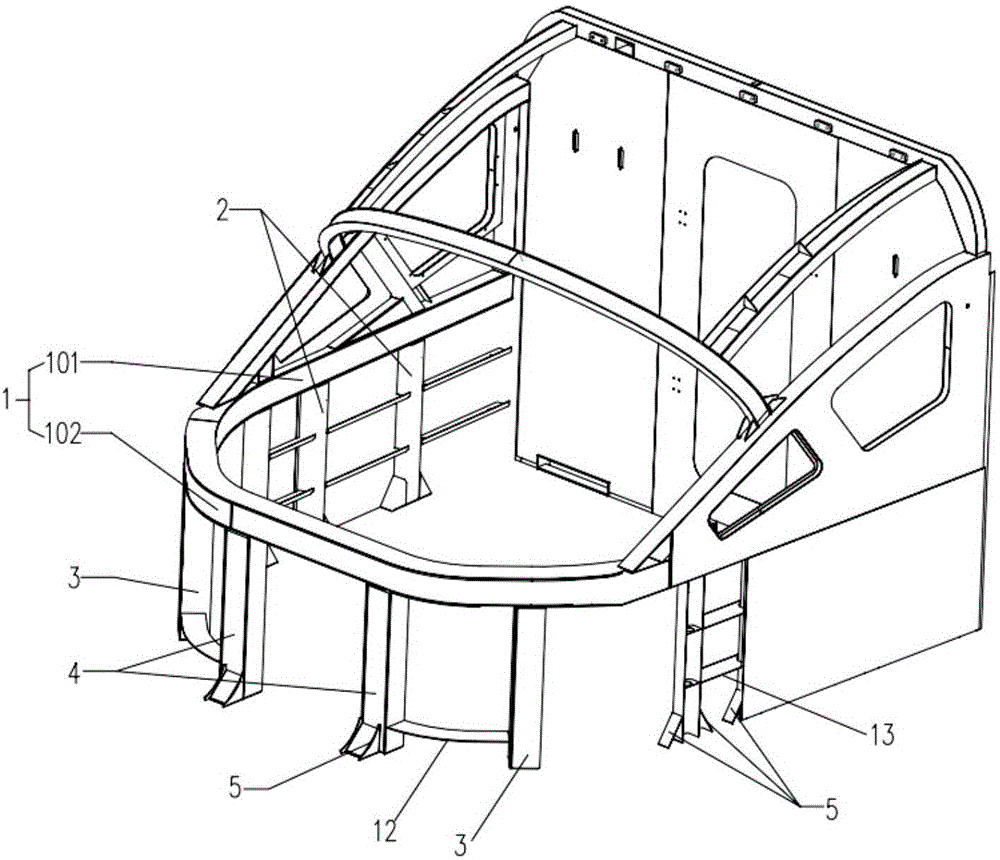

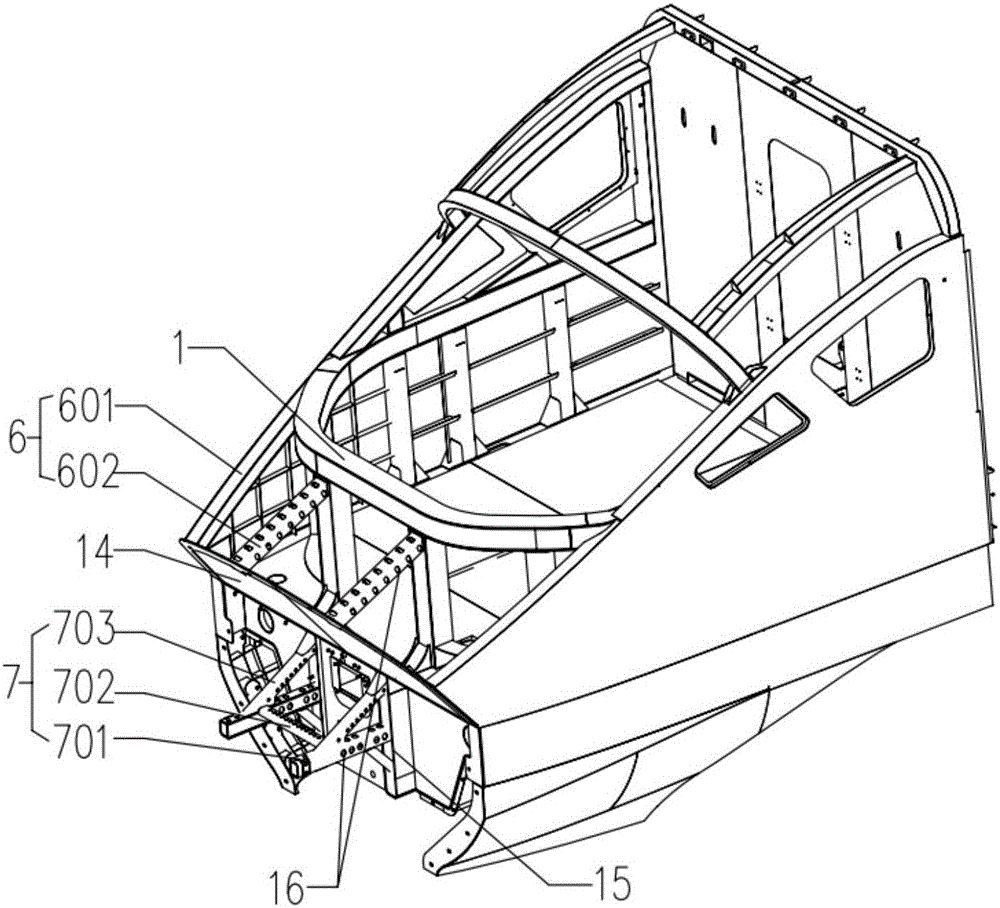

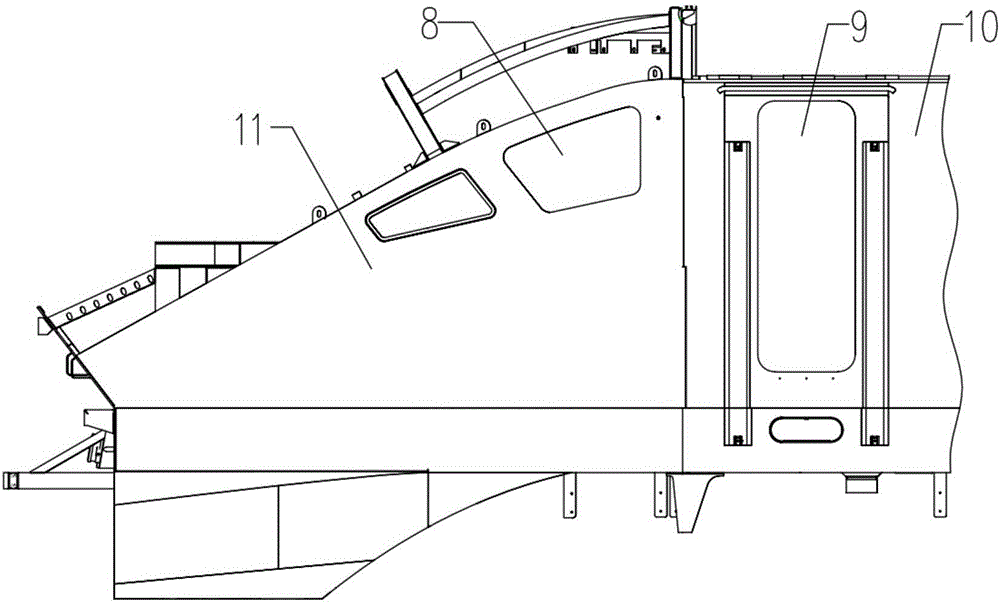

[0027] The anti-collision structure of the rail vehicle head of the present embodiment includes a front anti-collision column 4 arranged on the front end chassis of the driver's cab 11 and a corner post 3 arranged on the side of the front end chassis of the driver's cab 11. The front anti-collision column 4 and corner posts 3 are respectively distributed symmetrically along the traveling direction of the car body. The rail vehicle head anti-collision structure also includes a semi-circular anti-collision waist beam 1 and side anti-collision posts 2 arranged on the side chassis of the driver's cab 11. The anti-collision waist beam 1 is composed of a side anti-collision waist beam 101 and a front window anti-collision waist beam 102, and the side anti-collision waist beam 101 is fixed on the top of the side anti-collision pillar 2; Crash the waist beam 102 and be fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com