Automobile front axle assembly

A front axle assembly, automobile technology, applied in the directions of axles, wheels, vehicle parts, etc., can solve the problems of high production cost of wheel hub assembly, troublesome wheel hub bearing assembly, difficult after-sales replacement, etc., and achieve low after-sales replacement cost and after-sales replacement. Easy, save the effect of processing cost and mold opening cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

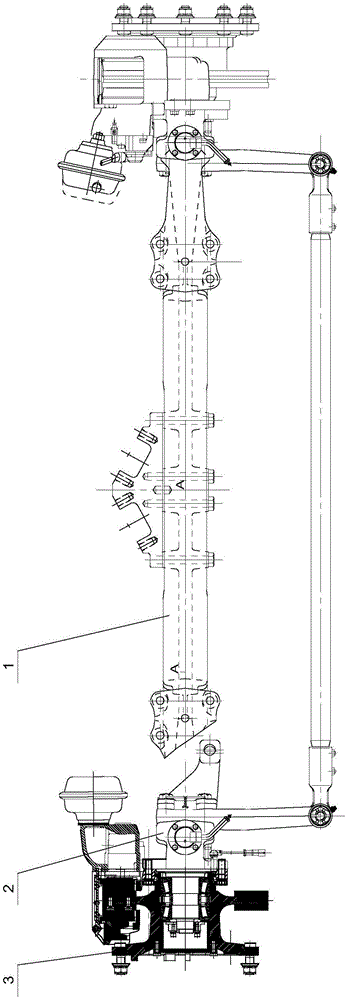

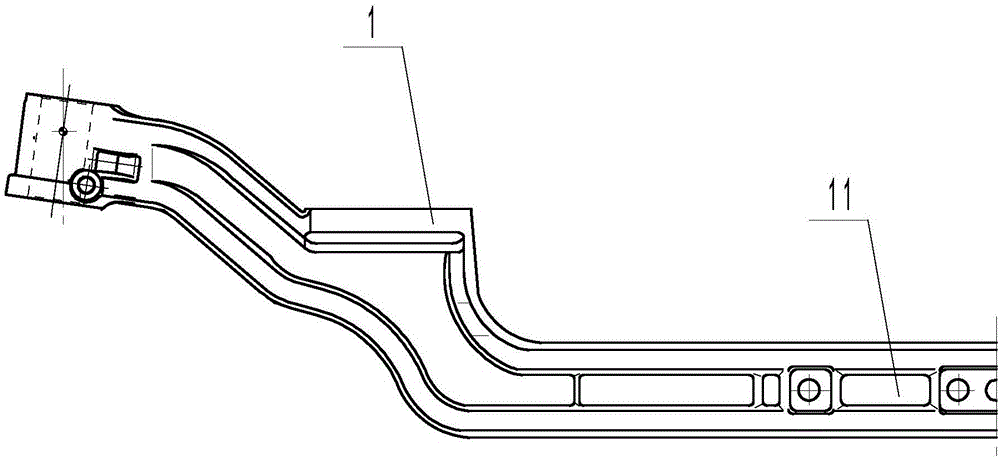

[0045] A kind of automobile front axle assembly, comprises front axle 1, the brake assembly 2 that is respectively installed with the two ends of front axle, wheel hub assembly 3; Wherein,

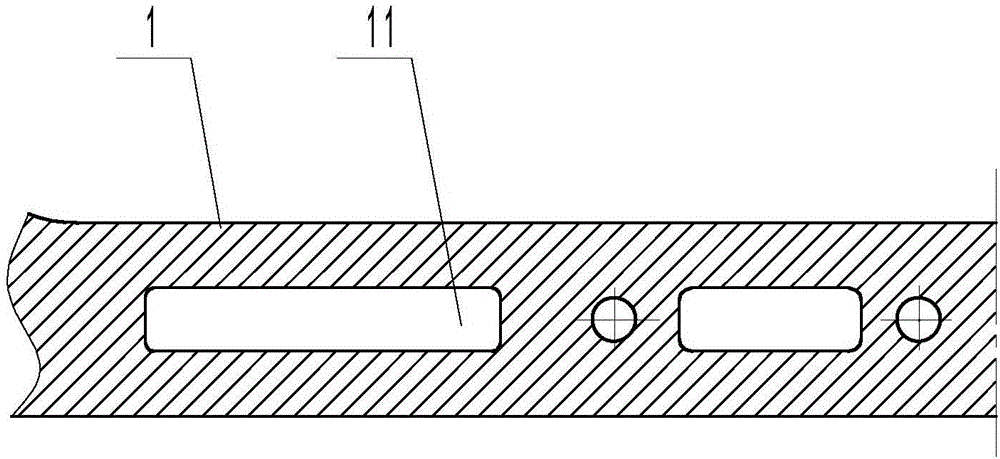

[0046] The front axle 1 is provided with a plurality of elongated through holes 11 for reducing weight, and the front axle 1 is made of high-strength 42CrMo material.

[0047] The hub assembly 3 includes a hub body 31, an outer bearing installed in the hub body 31, and an inner bearing. The hub body 31 is provided with a brake boss 311 at the position where the brake disc is installed. The left and right ends of the platform 311 are connected with friction plates 32, which are semi-circular, and there are four pieces in total; and a heat insulating plate 33 is installed between the friction plate 32 and the braking boss 311, and the heat insulating plate The thickness of 33 is 5mm, and it is made of high-strength nano-materials, which prevents the heat generated by the friction plate from ...

Embodiment 2

[0049] A kind of automobile front axle assembly, comprises front axle 1, the brake assembly 2 that is respectively installed with the two ends of front axle, wheel hub assembly 3; Wherein,

[0050] The front axle 1 is provided with a plurality of elongated through holes 11 for reducing weight, and the front axle 1 is made of high-strength 42CrMo material.

[0051] The hub assembly 3 includes a hub body 31, an outer bearing installed in the hub body 31, and an inner bearing. The hub body 31 is provided with a brake boss 311 at the position where the brake disc is installed. The left and right ends of the platform 311 are connected with friction plates 32, which are semi-circular, and there are four pieces in total; and a heat insulating plate 33 is installed between the friction plate 32 and the braking boss 311, and the heat insulating plate The thickness of 33 is 10mm, and it is made of high-strength nano-materials, which prevents the heat generated by the friction plate from...

Embodiment 3

[0053] A kind of automobile front axle assembly, comprises front axle 1, the brake assembly 2 that is respectively installed with the two ends of front axle, wheel hub assembly 3; Wherein,

[0054] The front axle 1 is provided with a plurality of elongated through holes 11 for reducing weight, and the front axle 1 is made of high-strength 42CrMo material.

[0055] The hub assembly 3 includes a hub body 31, an outer bearing installed in the hub body 31, and an inner bearing. The hub body 31 is provided with a brake boss 311 at the position where the brake disc is installed. The left and right ends of the platform 311 are connected with friction plates 32, which are semi-circular, and there are four pieces in total; and a heat insulating plate 33 is installed between the friction plate 32 and the braking boss 311, and the heat insulating plate The thickness of 33 is 8mm, and it is made of high-strength nano-materials, which prevents the heat generated by the friction plate from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com