Conjoined part injection mold

A technology for injection molds and parts, which is applied in the field of molds for integral injection molding of multiple parts, which can solve problems such as easy misalignment, low efficiency, and difficult assembly, and achieve the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

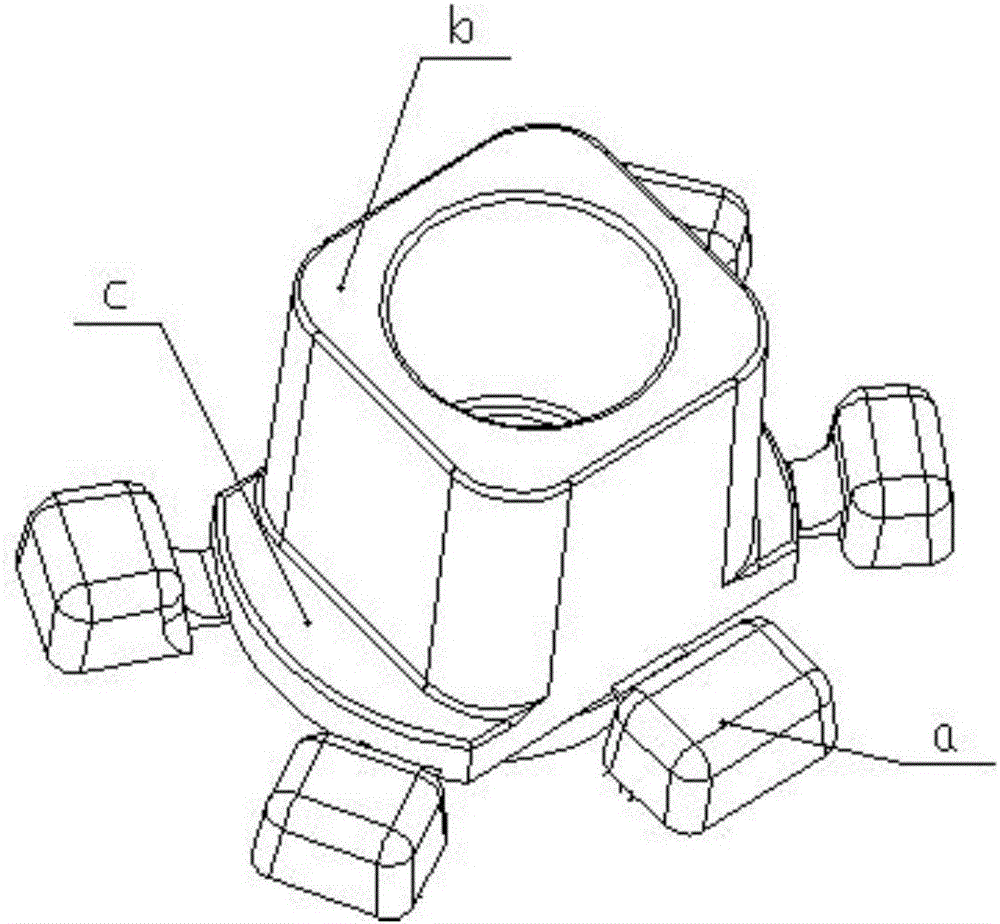

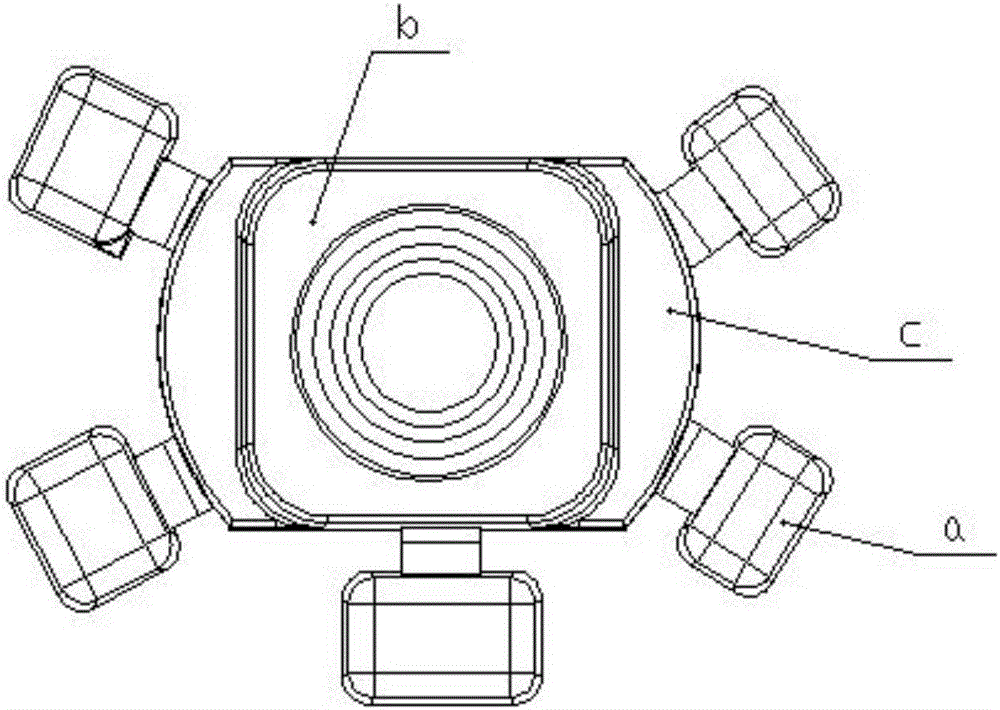

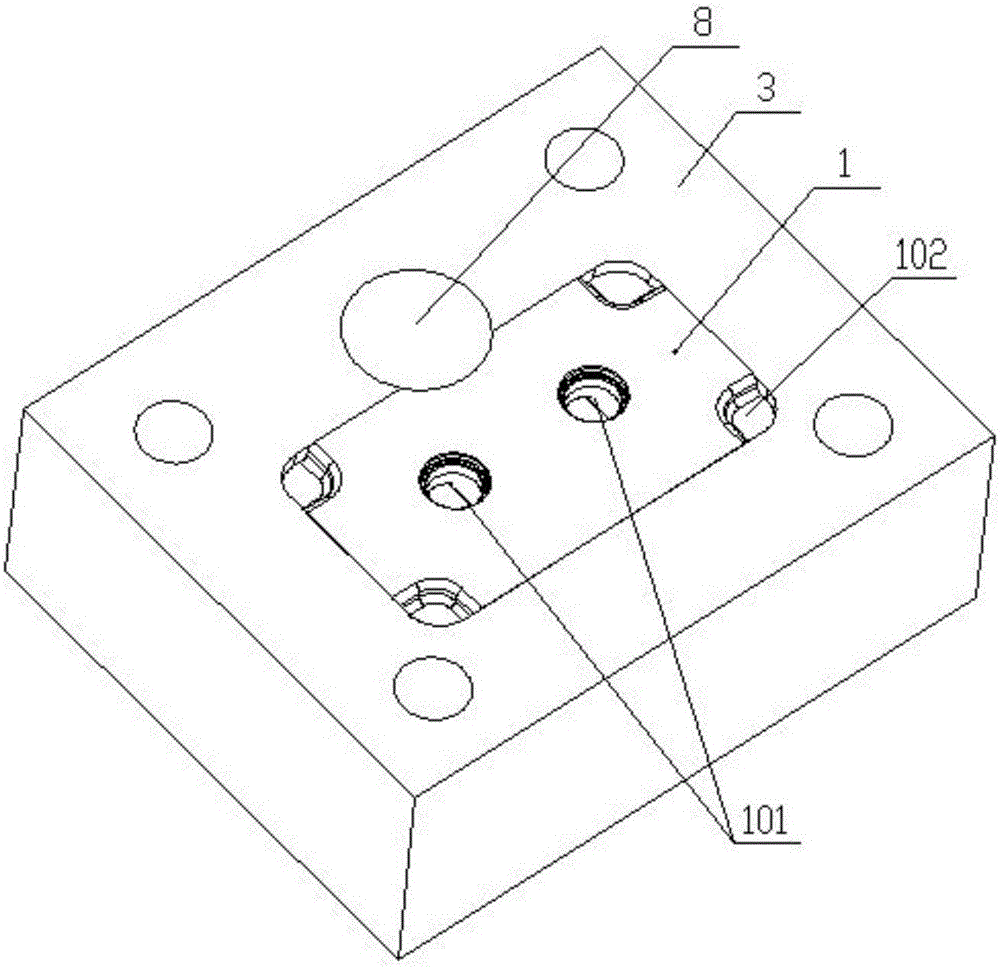

[0024] As shown in the figure, an injection mold for connected parts includes an upper mold 1 and a lower mold 2 for injection molding. The upper mold 1 is a rectangular parallelepiped structure with rounded corners, and the upper mold 1 is embedded in the upper mold base 3. The molding surface of the inner and upper mold 1 is flush with the mold embedded end face of the upper mold base, and the lower mold 2 is embedded in the lower mold base 4 .

[0025] Two circular blind holes 101 are arranged on the molding surface of the upper mold 1 along the center line of its length direction, and the two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com