Damping chassis of meal delivery robot

A food delivery robot and chassis technology, applied in manipulators, manufacturing tools, etc., can solve the problems of spilled dishes, low chassis, and high requirements on the stability of food delivery robots, so as to avoid spillage and reduce bumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

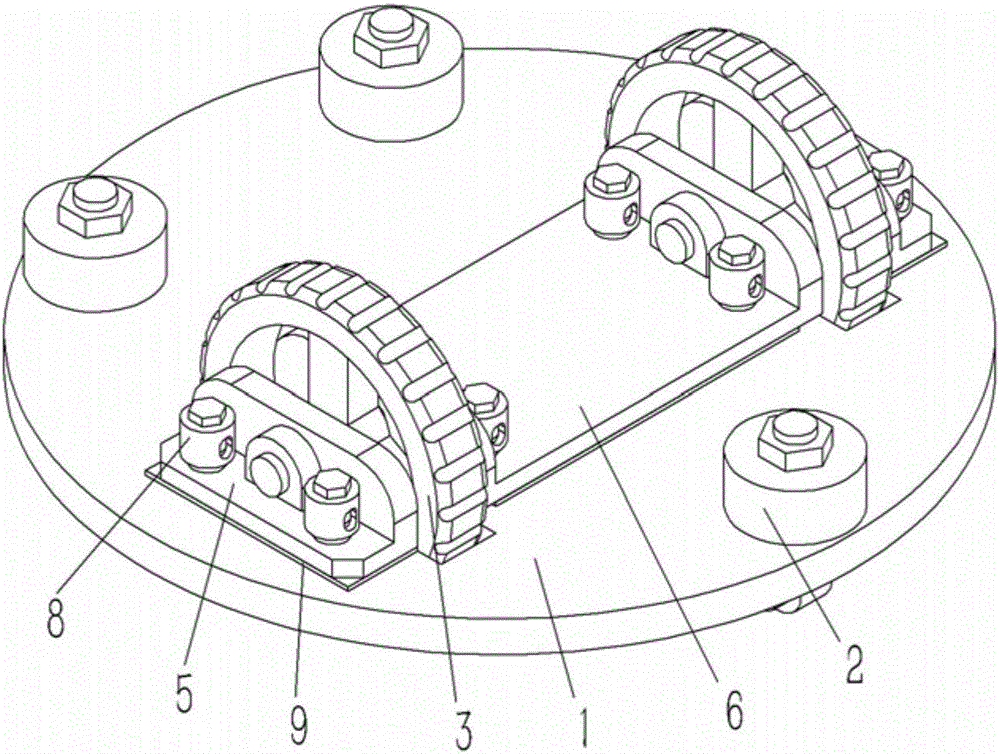

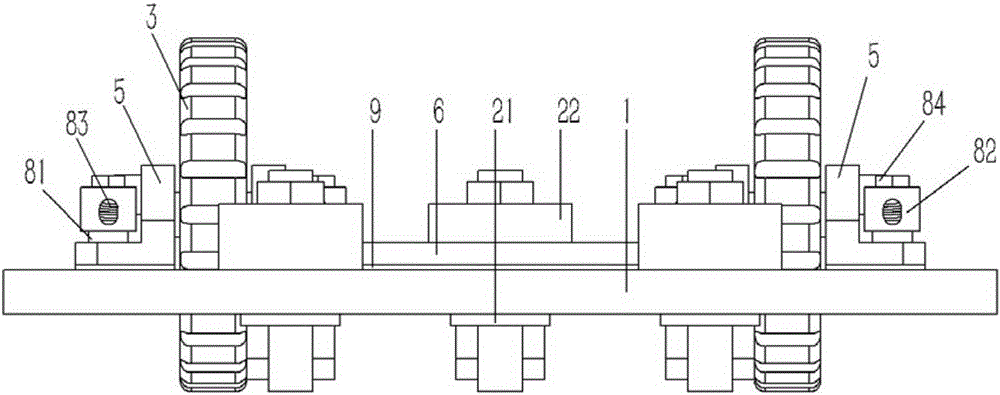

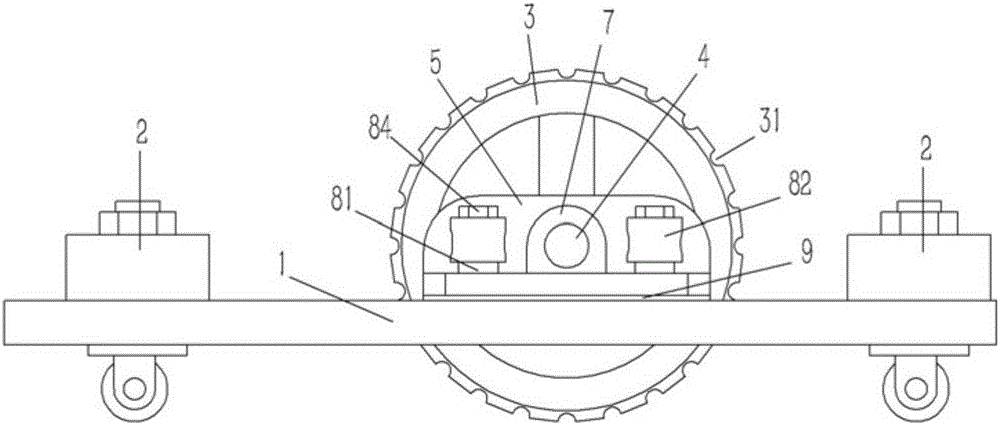

[0023] Example: see Figures 1 to 4 As shown, a shock-absorbing chassis of a food delivery robot includes a chassis 1, a universal wheel assembly 2 is fixed on the outer edge of the chassis 1, slots are formed on both sides of the chassis 1, and a drive is inserted into the slot of the chassis 1. Wheel 3, the chassis 1 on the outside of the driving wheel 3 is provided with an L-shaped support seat 5, the chassis 1 between the driving wheels 3 is provided with a "凵"-shaped motor support 6, and the driving wheel 3 is plugged A drive shaft 4 is fixed, and the two ends of the drive shaft 4 pass through the bearing seat 5 and the motor support 6 respectively and are hinged on the support seat 5 and the motor support 6 through the bearing seat 7. The motor support 6 and the support base 5 is fixed on the chassis 1 through an elastic connector 8, and a rubber pad 9 is sandwiched between the motor support 6 or the support seat 5 and the chassis 1;

[0024] The elastic connecting memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com