High-frequency brazing coil clamp

A high-frequency brazing and coil technology, which is applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve the problems of high-frequency coil center offset, re-welding, and high-frequency coil center offset, etc., to ensure that the center The effect of high position and repeatability accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

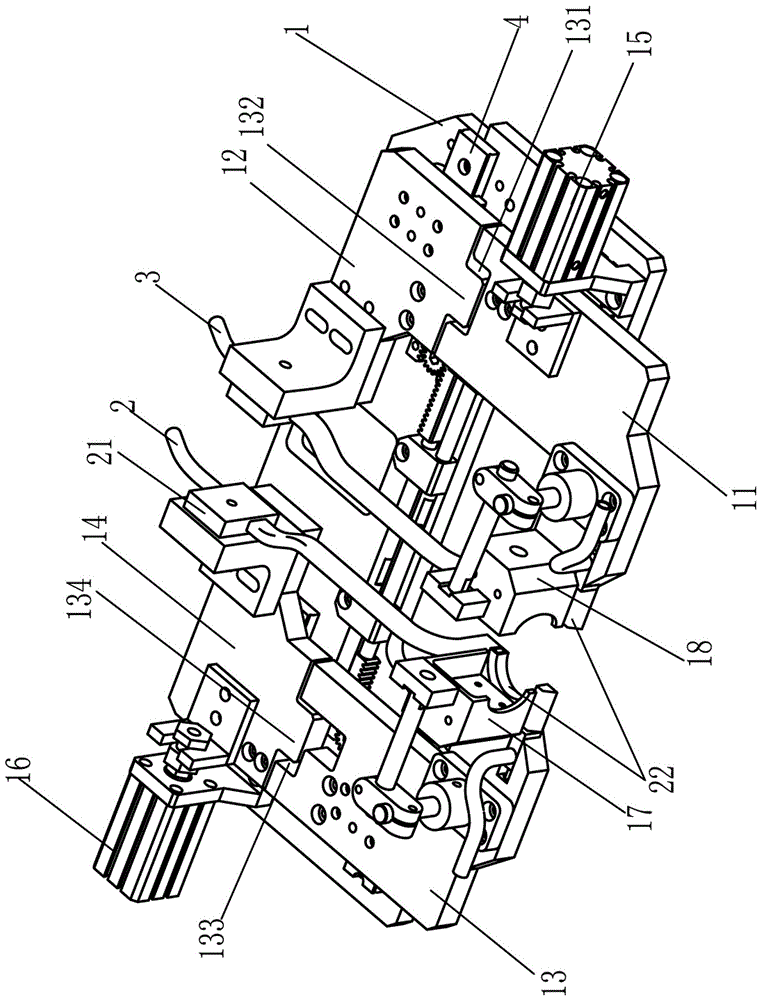

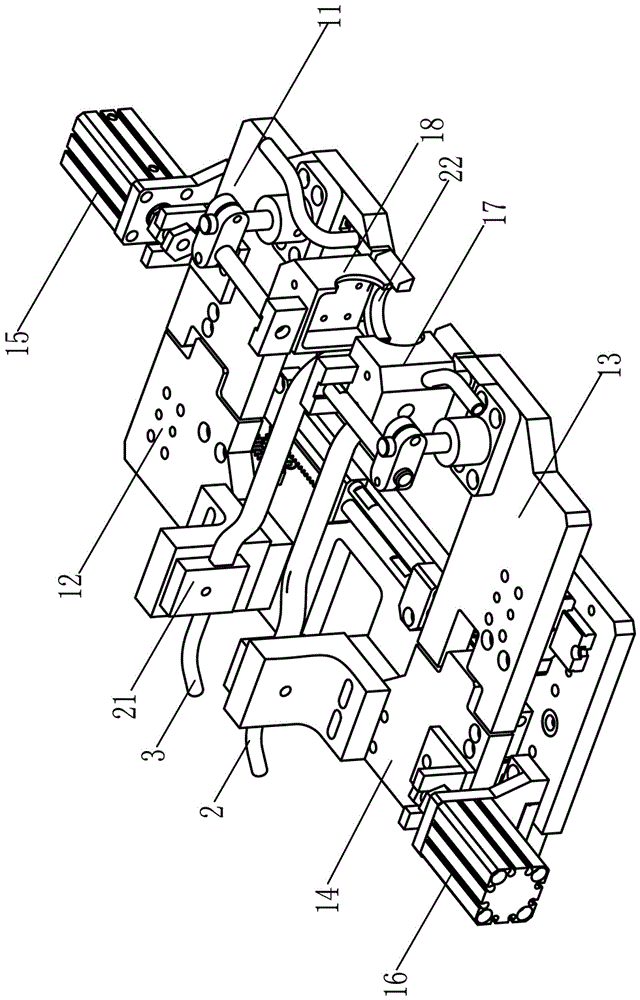

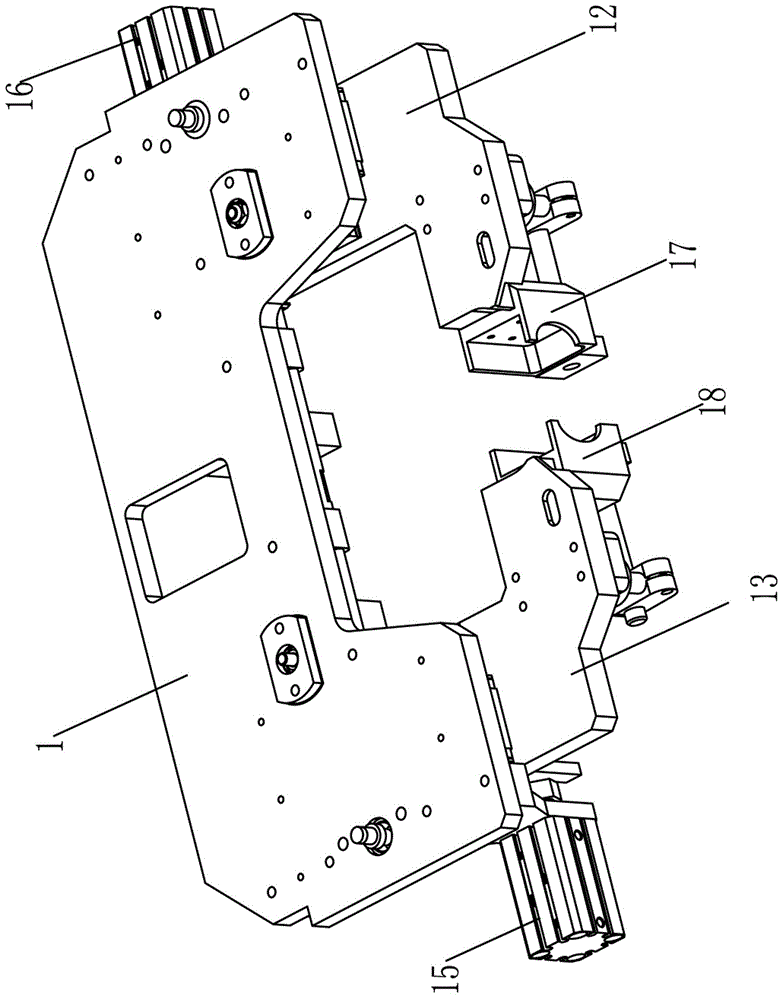

[0025] Embodiment one, see Figure 1 to Figure 4 As shown, a high-frequency brazing coil fixture includes a mounting base plate 1, a first welding rod 2, and a second welding rod 3. The right side of the mounting base plate 1 is slidably provided with a first sliding plate 11 and a second sliding plate. Plate 12, a third slide plate 13 and a fourth slide plate 14 are slidably provided on the left side of the installation base plate 1, the first slide plate 11 is set opposite to the third slide plate 13, the second slide plate 12 is connected to the fourth slide plate 14 is relatively arranged, the front end and the rear end of the first welding rod 2 are respectively arranged on the first sliding plate 11 and the second sliding plate 12, and the front end and the rear end of the second welding rod 3 are respectively provided with the third sliding plate 13 , On the fourth sliding plate 14, the front end of the first and second welding rods 3 is provided with a welding arc fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com