Wire saw spring limit press and its use method

A spring limit and press technology, which is applied in sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve the problem of inability to guarantee the spring position limit, and achieve the effect of simple structure and force bearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

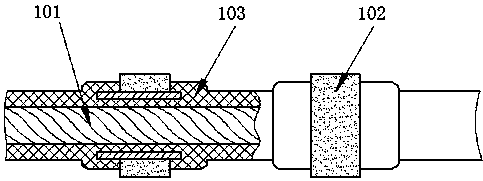

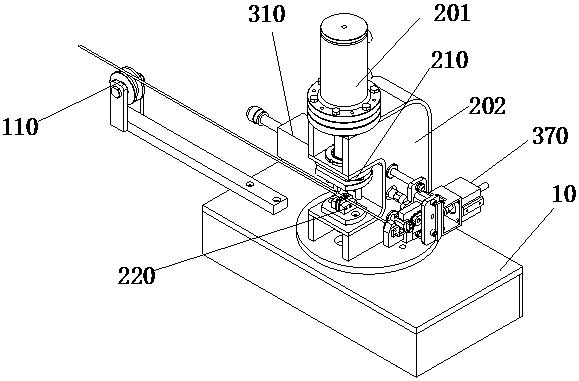

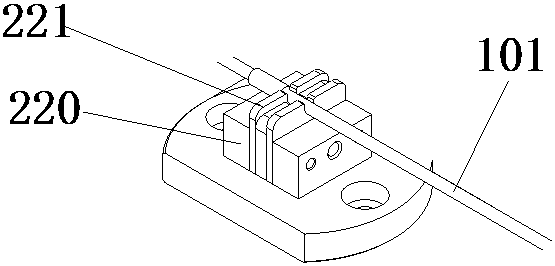

[0025] like Figure 1~6 Shown, a kind of wire saw spring limit press machine, comprises frame 10 and is arranged on frame 10 and is used for making diamond bead buckle the mold of steel wire rope, and described mold comprises mold and comprises upper mold 210 and is fixed on frame 10 Upper die 220, the upper die 10 is fixed on the hydraulic cylinder 201 for driving the upper die 210 to move up and down, the hydraulic cylinder 201 is fixed on the hydraulic cylinder seat 202, between the upper die 210 and the lower die 220 It has a hexagonal cavity, and in order to facilitate guidance, the frame is provided with a guide wheel 110 for guiding the movement of the wire saw.

[0026] In this embodiment, the hydraulic cylinder seat 202 is bow-shaped, the lower mold 220 is fixed on the table top of the frame 10, and the hexagonal cavity is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com