Hydraulic drawing forming method for oil pan without draft angle

A technology of oil pan and draft angle, which is used in forming tools, petroleum industry, machinery and equipment, etc., can solve the problems of uneven material thickness, cracking, wrinkling, etc., and achieve the effect of minor scratches and friction solving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

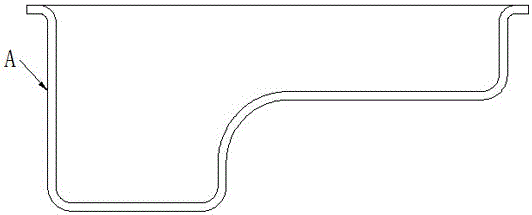

Image

Examples

Embodiment 1

[0018] Embodiment 1, preparation anti-extrusion medium:

[0019] Anti-extrusion medium, by mass percentage, consists of the following components: 30% mineral oil; 10% carboxylate; 10% boric acid or borate; 20% alkanolamine; 9% sodium petroleum sulfonate; 11 % Propylene Glycol Ether; 9% Nonionic Surfactant; 0.5% Defoamer; 0.5% Organic Sulfur Bactericide;

[0020] Mix the components uniformly to obtain the anti-extrusion medium.

Embodiment 2

[0022] Anti-extrusion medium for hydraulic drawing of oil sumps without draft angle, consisting of the following components, by mass percentage: 31% mineral oil, 9% carboxylate, 8% boric acid or borate , 21% alkanolamine, 11% sodium petroleum sulfonate, 9% propylene glycol ether, 10% nonionic surfactant, 0.7% defoamer, 0.3% organic sulfur fungicide; Mix the components uniformly to obtain the anti-extrusion medium.

[0023] In the present invention, the carboxylate is selected from one of formate, acetate or oxalate; the sodium or potassium salt of formic acid, the sodium or potassium salt of acetic acid, the sodium of oxalate salt or potassium salt.

[0024] In the present invention, the borate is selected from one of sodium borohydride and ammonium hydrogen borate.

[0025] In the present invention, when boric acid or borate is selected, boric acid is preferred.

[0026] In the present invention, the alkanolamine is selected from one of N,N-diethylethanolamine, N,N-dimethy...

Embodiment 3

[0041] The method for hydraulic drawing and forming of oil pan without draft angle, the steps are as follows:

[0042] (1) Install the drawing forming die on the hydraulic drawing machine, inject the anti-extrusion medium of Example 1 on the top material plate in the cavity of the concave mold to ensure that the top material plate is completely covered;

[0043] (2) Put a flat material on the cavity filled with medium, and apply conventional drawing oil on the punch;

[0044] (3) Mold closing: Start the hydraulic drawing machine to close the upper drawing mold and the lower drawing mold of the drawing mold;

[0045] (4) Material return: The formed engine oil pan exits the drawing forming die.

[0046] The effect of embodiment 3: through 500 product processings, pass rate is at 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com