Ballpoint pen ballpoint extruding device

A technology of an extrusion device and a ball-point pen, which is applied to metal extrusion dies and other directions, can solve the problems of uneven thickness of material lines, and achieve the effects of solving uneven thickness, convenient use and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

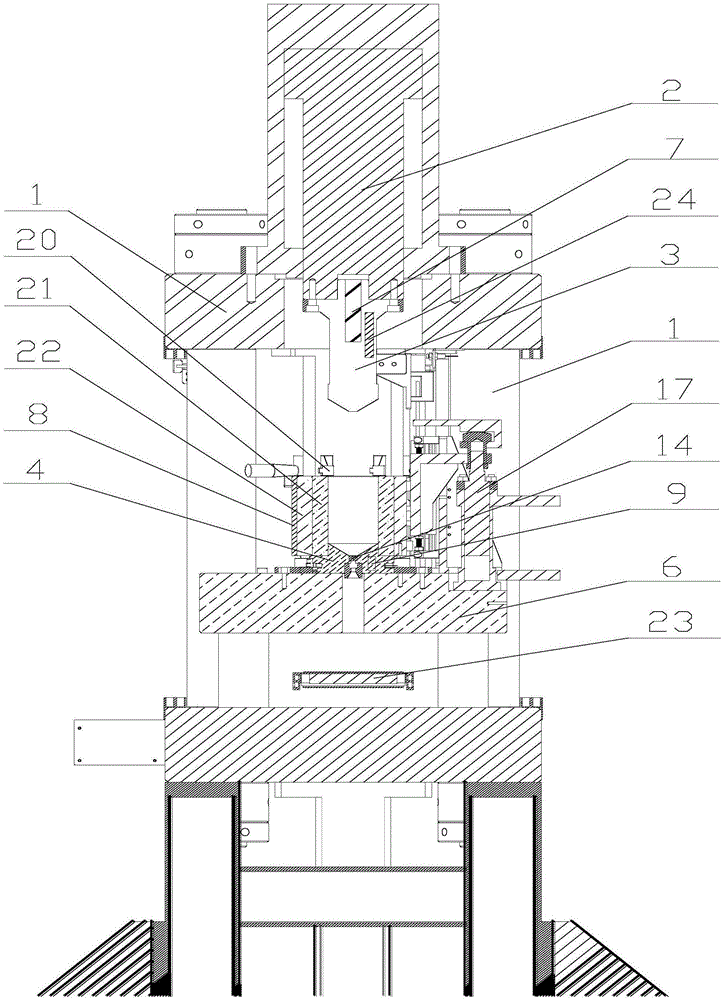

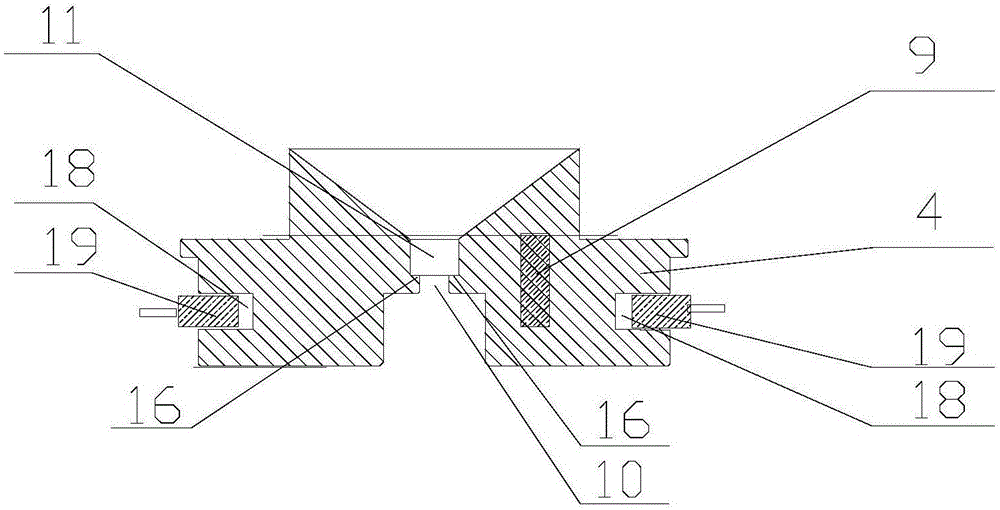

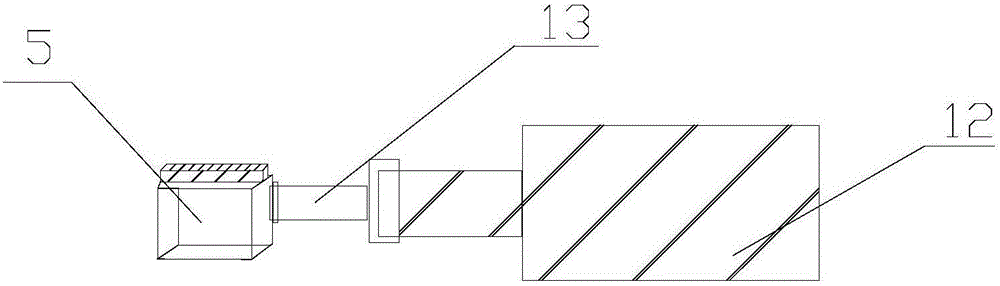

[0024] like Figure 1-4 As shown, the present invention is a ball-point extruding device for a ballpoint pen, comprising a support 1, a first oil cylinder 2, a die head 3, a discharge barrel, a bottom mold 4 with a hole in the middle, a movable block 5 and a support 6, the The support 1 is provided with a first oil cylinder 2, the lower part of the first oil cylinder 2 is provided with a die head 3, the inside of the die head 3 is provided with a first heating rod 7, and the lower part of the die head 3 is provided with the discharge barrel , the periphery of the discharge barrel is provided with a heating belt 8, the bottom of the discharge barrel is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com