The structure and use method of wafer combination wheel of cleaning equipment after cmp

A combined wheel and post-cleaning technology, applied in the directions of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of easy jamming of the wafer idler, affecting the accuracy of speed measurement, and large swing of the wafer idler, so as to improve the rigidity. , to ensure the rationality of the layout, the effect of reducing the swing of the idler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

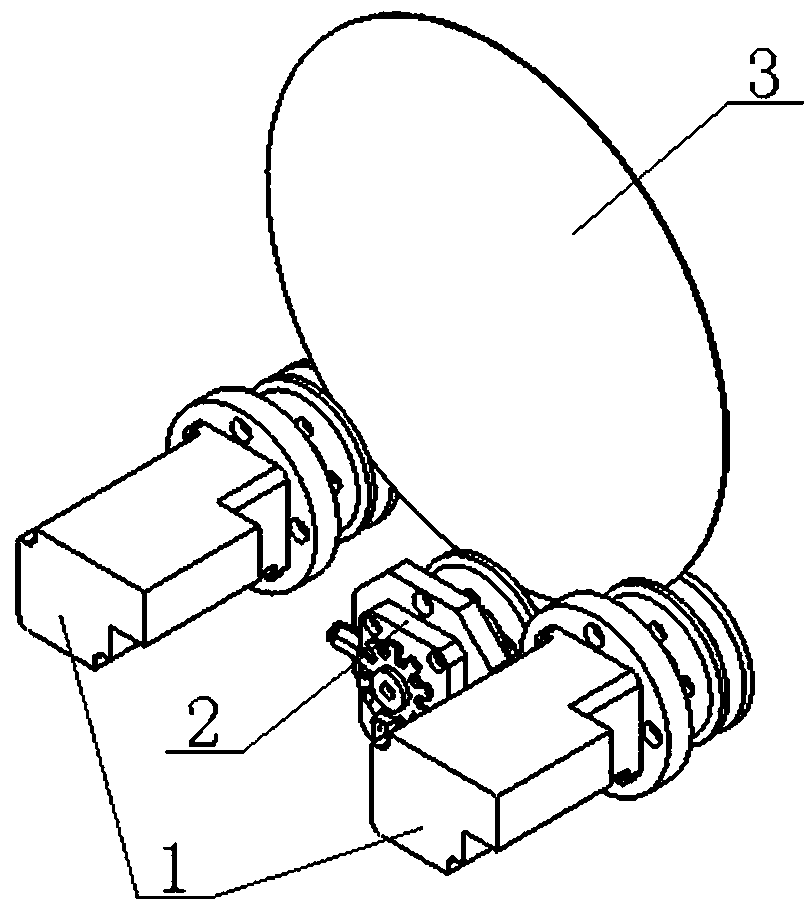

[0043] Examples see figure 1 , figure 2 As shown, the wafer combination wheel structure of this CMP post-cleaning equipment includes a drive unit 1 arranged concentrically with the center of the wafer 3, and a driven unit 2 vertically arranged concentrically with the center of the wafer 3. The coupling surfaces of the driving unit 1 and the driven unit 2 are longitudinally the same.

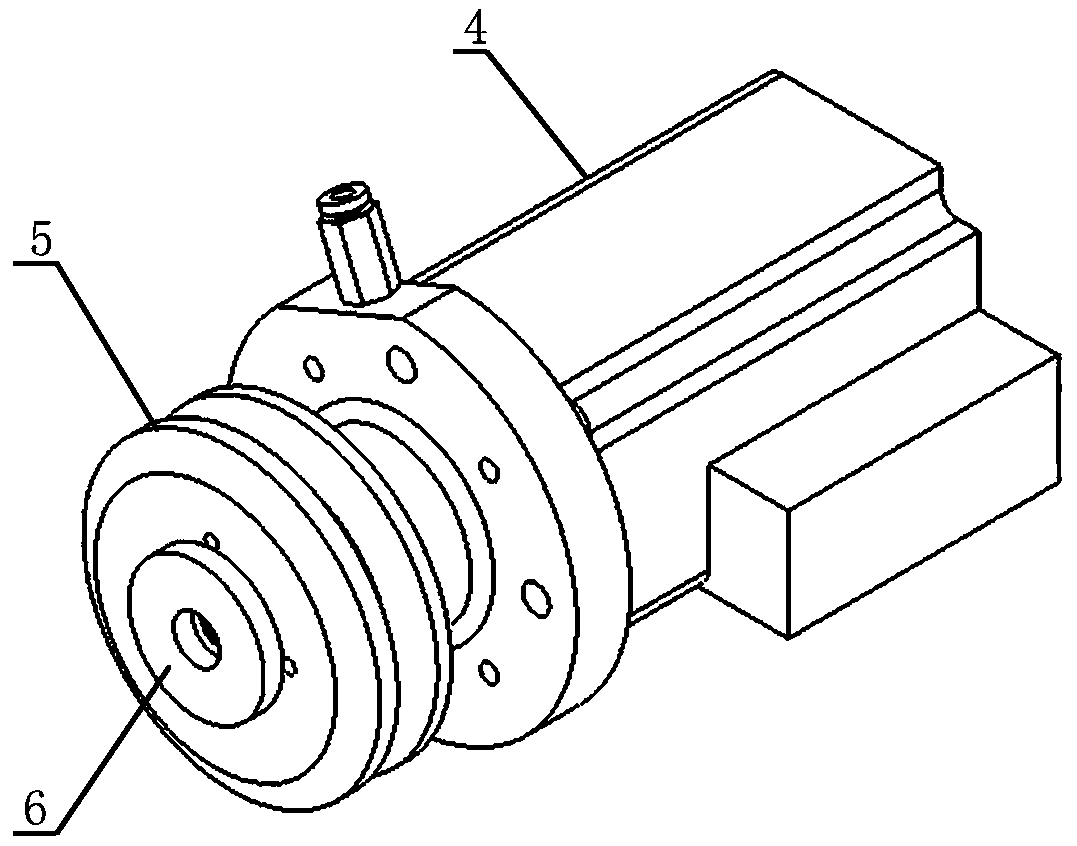

[0044] see image 3 , Figure 4 As shown, the drive unit 1 includes a drive shaft unit 4 , a drive wheel unit 5 that is socketed with the drive shaft unit 4 , and a pressure ring a6 that locks the drive wheel unit 5 to the drive shaft unit 4 .

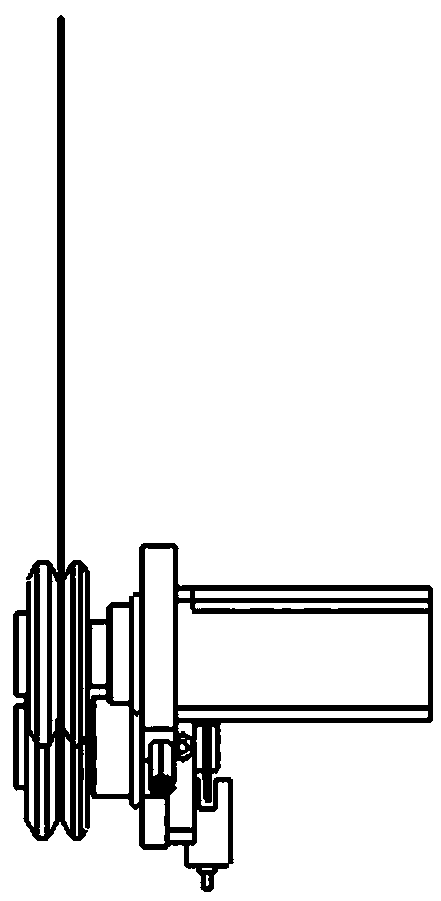

[0045] see Figure 5 As shown, the drive shaft unit 4 includes a base a7, a drive shaft 9, a motor 10 and a through joint a11. The neck of the base a7 is covered with an O-ring a8. The motor 10 and the base a7 are fitted and fastened in the form of a hole shaft, and the through joint a11 and the base a7 are screwed and sealed in a threaded manner. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com