Plank outer surface sizing treatment device

A technology for processing device and wood board, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of high labor intensity of workers, difficult to guarantee product quality, and great influence of human factors, so as to improve the efficiency of glue spraying, ensure the service life, The effect of improving gluing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

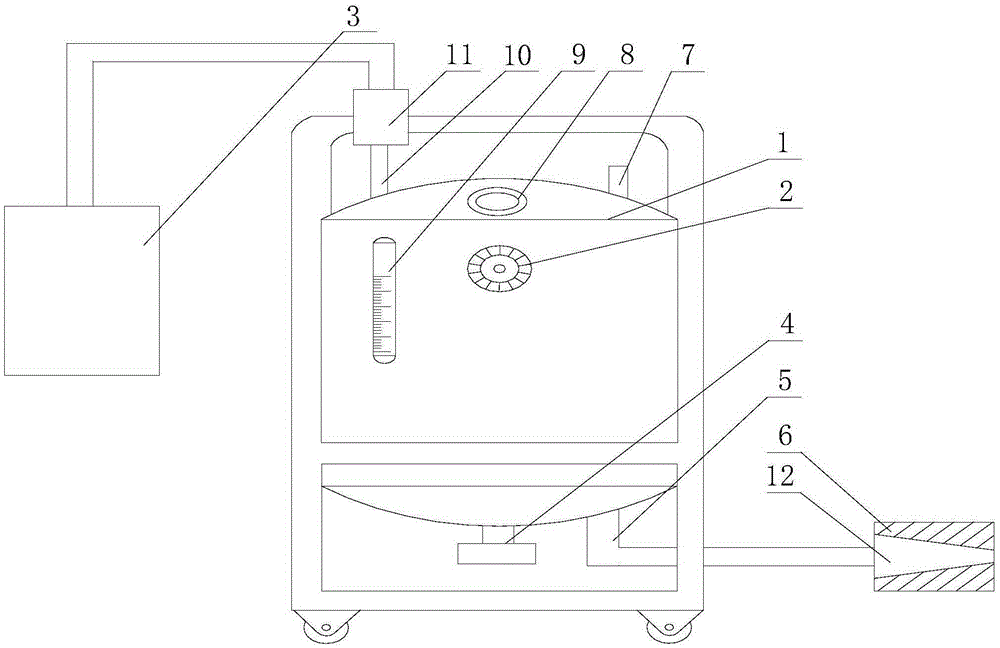

[0020] Such as figure 1 As shown, the present embodiment includes a movable seat and a tank body 1 fixed on the movable seat. A glue inlet 8, an air inlet pipe 10 and an air outlet pipe 7 communicating with the inside of the tank body 1 are respectively provided at the top of the tank body 1. The bottom end of the tank body 1 is provided with a rubber outlet pipe 5 communicating with the inside of the tank body 1, the end of the air inlet pipe 10 communicates with the output end of the air pump 3, and the rubber outlet pipe 5 is connected to the nozzle 6; it also includes a liquid level gauge 9, the The liquid level gauge 9 is arranged on the outer surface of the tank body 1, the nozzle 6 includes a body, and a spray flow channel 12 is opened in the body, and the inner diameter of the spray flow channel 12 decreases along the glue liquid exiting direction. When the present invention works, a certain amount of glue is first filled into the inside of the tank 1 through the glue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com