Formaldehyde adsorbent for air purification and preparation method and application thereof

A formaldehyde adsorption and air purification technology, applied in the field of pollution treatment, can solve the problem of high production cost of activated carbon, and achieve the effect of significant adsorption effect, low cost and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

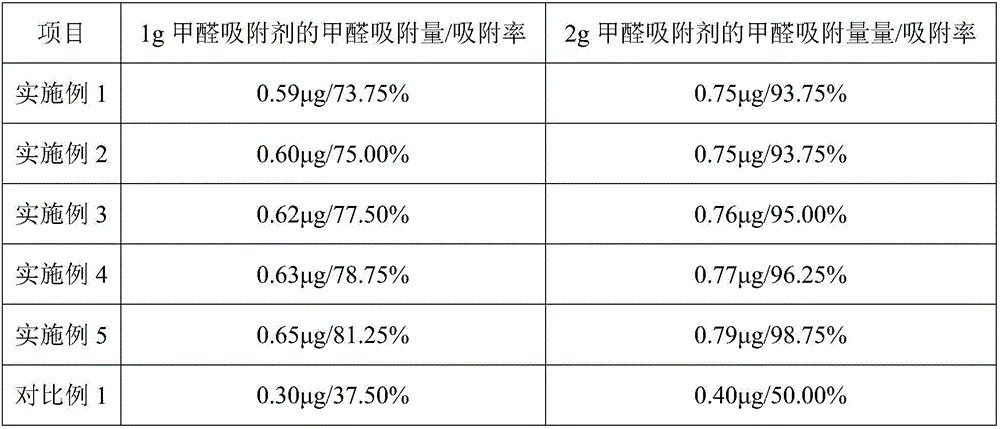

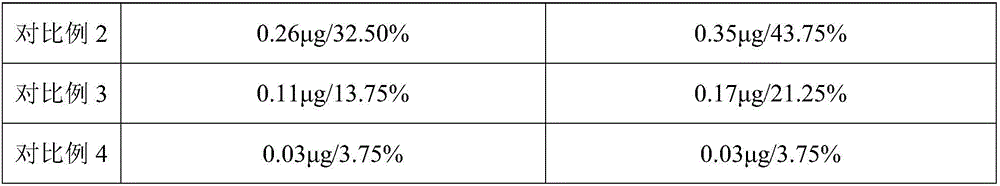

Examples

Embodiment 1

[0021] In the embodiment of the present invention, a formaldehyde adsorbent for air purification, in parts by mass, consists of the following raw materials: 56 parts of calcium carbonate, 16 parts of hydrated titanium dioxide, 32 parts of glycerol, 12 parts of evodia lactone, bromination 5 parts of aluminum and 92 parts of deionized water.

[0022] The preparation method of the formaldehyde adsorbent for air purification includes the following steps:

[0023] (1) Mix the hydrated titanium dioxide, aluminum bromide and half of the formula amount of deionized water in proportion, and stir at 220r / min for 20min to obtain mixture A;

[0024] (2) Slowly add glycerol in proportion to Mixture A, continue to stir at 220r / min for 10 minutes to obtain Mixture B;

[0025] (3) Mix the evodia lactone and the remaining deionized water in proportion, and stir for 15 minutes at a speed of 120r / min to obtain a mixture C;

[0026] (4) Pour the mixture B into the mixture C slowly, and stir for 10 min at ...

Embodiment 2

[0029] In the embodiment of the present invention, a formaldehyde adsorbent for air purification, in parts by mass, consists of the following raw materials: 62 parts of calcium carbonate, 11 parts of hydrated titanium dioxide, 37 parts of glycerol, 8 parts of evodia lactone, bromination 7 parts of aluminum and 87 parts of deionized water.

[0030] The preparation method of the formaldehyde adsorbent for air purification includes the following steps:

[0031] (1) Mix the hydrated titanium dioxide, aluminum bromide and half of the formula amount of deionized water in proportion, and stir for 15 minutes at a speed of 250r / min to obtain a mixture A;

[0032] (2) Slowly add glycerol to the mixture A in proportion, continue to stir at a speed of 250r / min for 8 minutes to obtain the mixture B;

[0033] (3) Mix the evodia lactone and the remaining deionized water in proportion, and stir for 12 minutes at a speed of 150r / min to obtain a mixture C;

[0034] (4) Pour the mixture B into the mixtur...

Embodiment 3

[0037] In the embodiment of the present invention, a formaldehyde adsorbent for air purification, in parts by mass, is composed of the following raw materials: 58 parts of calcium carbonate, 15 parts of hydrated titanium dioxide, 34 parts of glycerol, 12 parts of evodia lactone, bromination 5 parts of aluminum and 90 parts of deionized water.

[0038] The preparation method of the formaldehyde adsorbent for air purification includes the following steps:

[0039] (1) Mix the hydrated titanium dioxide, aluminum bromide and half of the formula amount of deionized water in proportion, and stir at 220r / min for 20min to obtain mixture A;

[0040] (2) Slowly add glycerol in proportion to Mixture A, continue to stir at 220r / min for 10 minutes to obtain Mixture B;

[0041] (3) Mix the evodia lactone and the remaining deionized water in proportion, and stir for 15 minutes at a speed of 120r / min to obtain a mixture C;

[0042] (4) Pour the mixture B into the mixture C slowly, and stir for 10 min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com