Method for producing bamboo grid packing

A manufacturing method, bamboo grid technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the problems of mildew and decay, short maturity time, moth-eaten, etc., and achieve service life. Long, easy to reproduce, and completely environmentally friendly in service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

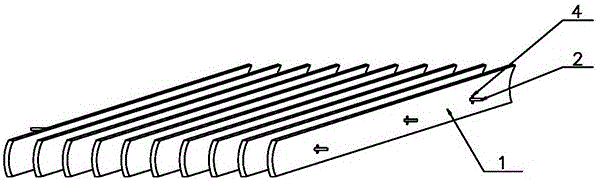

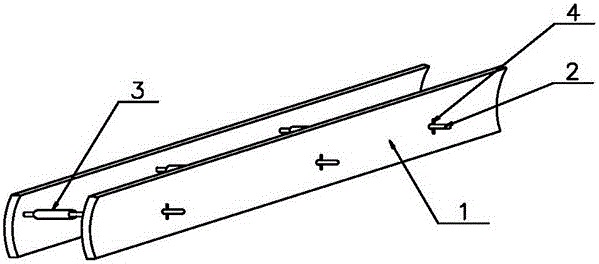

[0048] Preparation specification is the method for 1000*1000*40 mm bamboo grid filler, comprises the steps:

[0049] (1) Bamboo reinforcement and drying: select fresh bamboo tubes that are 5 to 6 years old, with an outer diameter range of φ60mm to 120mm and a wall thickness of 5mm to 10mm, sawed and cut into 1000mm long, and undergo rapid heat treatment with high temperature saturated steam at 140°C for 30 minutes, and then dry at high temperature. Dry at 96°C for 44 hours until the moisture content is 16%~18%, then saw it into arc-shaped bamboo slices 1 with a width of 40mm, and finally drill 3 holes at a distance of 150mm from the two ends and the middle part;

[0050] (2) Production of connected round bamboo poles 2: select fresh small-diameter round bamboos that are 5-6 years old and have an outer diameter of φ8mm-11mm, saw and cut them into 1010mm long, heat-treat with high-temperature saturated steam at 140°C for 40min, and then reheat Compress it into a uniform round ba...

Embodiment 2

[0054] Preparation specification is the method for 1200*650*40 mm bamboo grid filler, comprises the steps:

[0055] (1) Bamboo reinforcement and drying: select fresh bamboo tubes that are 5 to 6 years old, with an outer diameter range of φ80mm to 120mm and a wall thickness of 6mm to 11mm, sawed and cut into 1200mm long, and undergo rapid heat treatment with high temperature saturated steam at 180°C for 15min, and then Dry at a temperature of 100°C for 30 hours to a moisture content of 15-20%, then saw it into arc-shaped bamboo slices 1 with a width of 40mm, and finally drill 3 holes at a distance of 150mm from the two ends and in the middle;

[0056] (2) Production of connected round bamboo poles 2: select fresh small-diameter round bamboos that are 5-6 years old and have an outer diameter of φ8mm-11mm, saw and cut them into 660mm long, undergo rapid heat treatment with high-temperature saturated steam at 180°C for 10 minutes, and then pass through The round rod processing equ...

Embodiment 3

[0060] The preparation specification is the method for 1000*1000*40 mm bamboo lattice packing, has the following steps to form:

[0061] (1) Bamboo reinforcement and drying: select fresh bamboo tubes that are 5-6 years old, with an outer diameter range of φ60mm-120mm and a wall thickness of 5-10mm, sawed and cut into 1000mm long, and subjected to rapid heat treatment with high-temperature saturated steam at 140°C for 30 minutes at high temperature, and then At a temperature of about 105°C, dry for 25 hours until the moisture content is 15-20%, then saw it into arc-shaped bamboo slices with a width of 40mm, and finally drill 3 holes at a distance of 150mm from the two ends and in the middle;

[0062] (2) Production of connected round bamboo poles: select fresh small-diameter round bamboos that are 5-6 years old and have a diameter of φ8mm-11mm, saw and cut them into 1010mm lengths, undergo rapid heat treatment with high-temperature saturated steam at 140°C for 40 minutes, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com