Multistage combined type high-efficiency heat-exchanging dust-removing device and using method thereof

A heat exchange dust removal and combined technology, applied in the field of washing, dust removal and heat exchange devices, can solve the problems of poor cooling effect, large solvent consumption, easy blockage, etc., and achieve the effect of reducing consumption, saving energy and material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

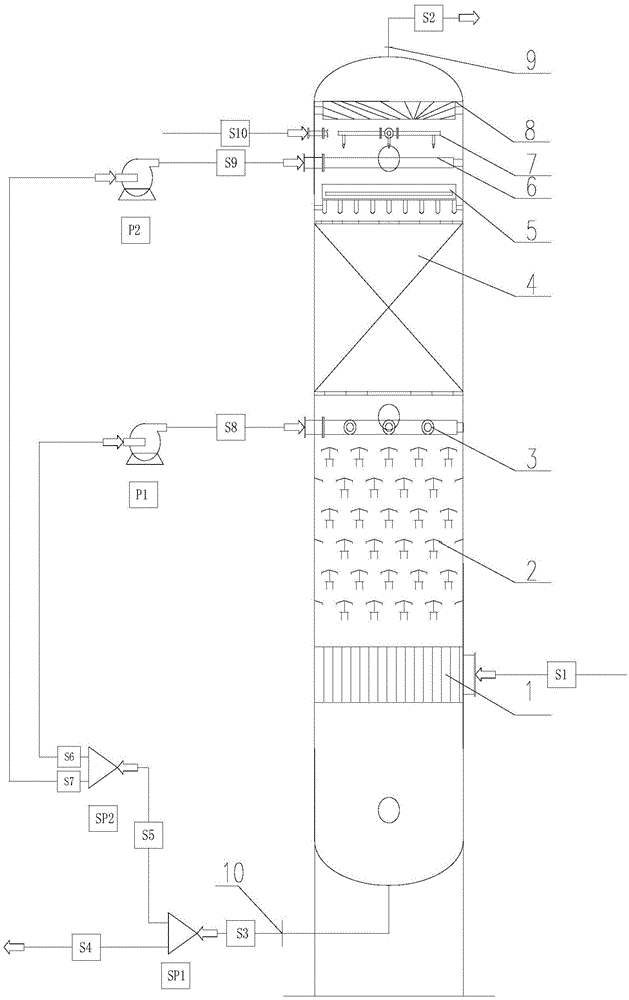

[0054] Example: see attached figure 1 , The invention is a multi-stage combined high-efficiency heat exchange and dust removal device.

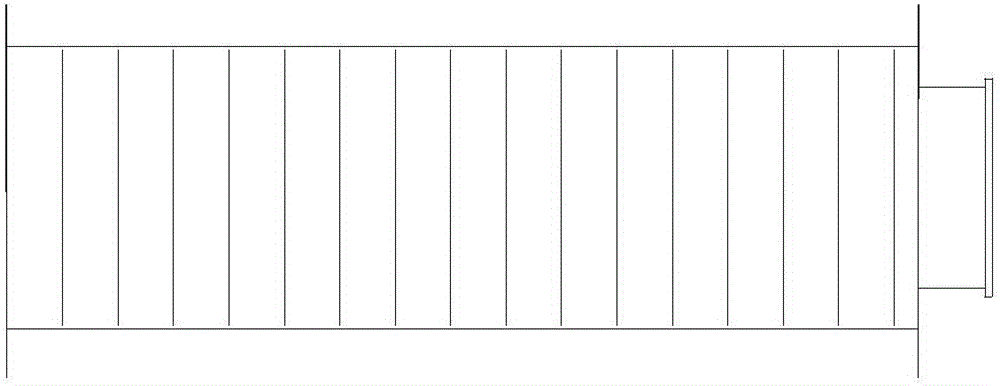

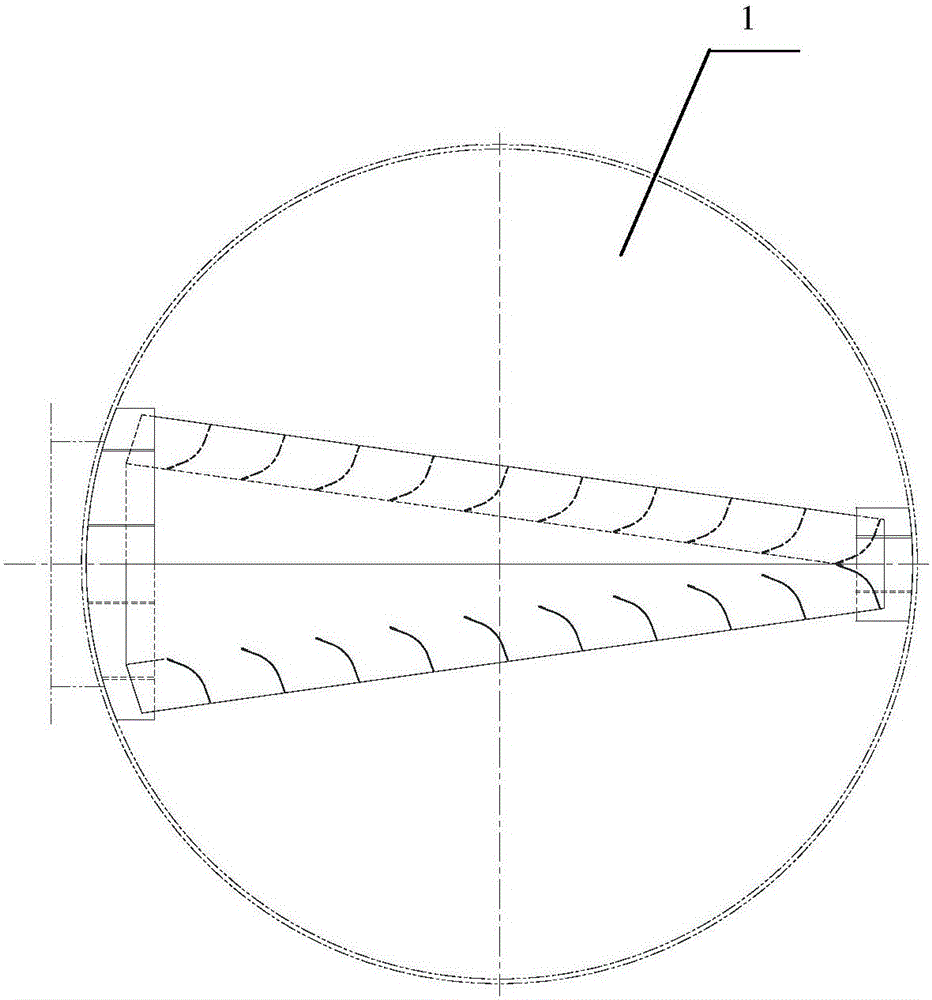

[0055] The multi-stage combined high-efficiency heat exchange and dedusting device of the present invention, the tower internals arranged from bottom to top include in turn: (1) a louver gas distributor 1 (such as Figure 2-a , 2-b ), the distance between the center line of the gas distributor and the top of the uppermost herringbone baffle is 1.4 to 2 times the diameter of the gas inlet; (2) 6 to 10 layers of herringbone baffles with openings are set in the initial washing section 2 (such as Figure 3-a , 3-b ), the width of the baffle plate of the herringbone baffle is 1 / 8~1 / 15 of the tower diameter, and the distance between each layer of herringbone trays is 600-900mm; (3) The initial washing section washing liquid is set above the herringbone baffle Distribution pipe 3 (such as Figure 4 ), the distance from the centerline of the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com