High-wind-quantity purification fresh air machine using hollow fibrous membrane as main filtering material

A technology of fiber membrane and large air volume, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, and separation of dispersed particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

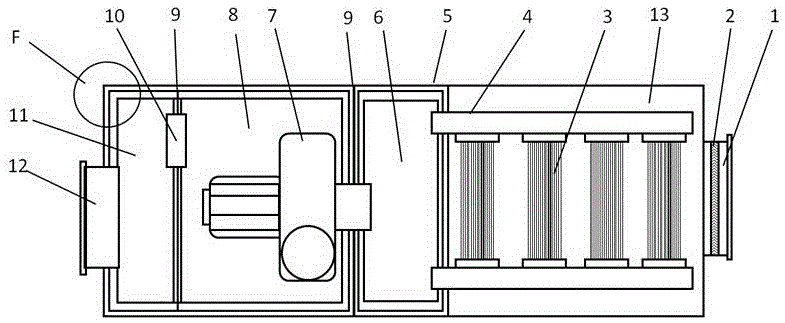

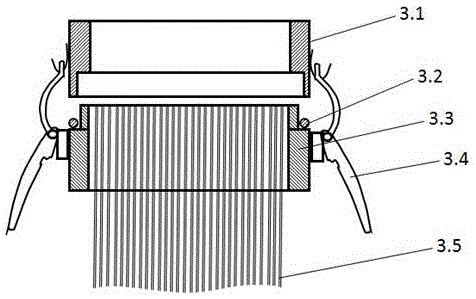

[0020] The present invention provides a solution for a large air volume purification fresh air machine with a hollow fiber membrane as the main filter material, and its specific implementation will be disclosed in more detail through an example below. However, this does not limit the further scope covered by the spirit of the claims of the present invention.

[0021] The cabinet (5) is a casing made of sheet metal.

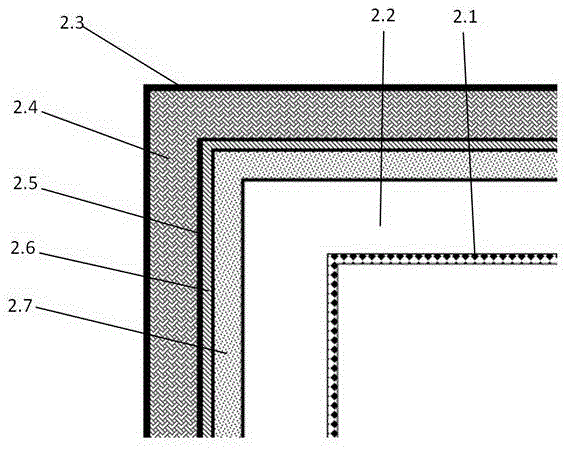

[0022] The air inlet assembly (1) can be a square or circular flange joint structure, and its caliber should be compatible with the design air volume of the whole machine; the pre-filter assembly (2) is installed in the air inlet assembly Among (1), it can be composed of interception net, coarse filter net and medium-efficiency filter net, or one or two of them. The pre-filtration technology itself is a mature technology in the fresh air treatment industry, but it is not a new technology for the fresh air filter device with hollow fiber membrane as the main filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com