Electric unloading granary with real-time grain monitoring function

一种实时监控、功能的技术,应用在电动卸粮粮仓领域,能够解决不能粮仓内储粮探查和监控、弊害发现慢、功能单一等问题,达到有利于小型化、成本低、结构紧凑简化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

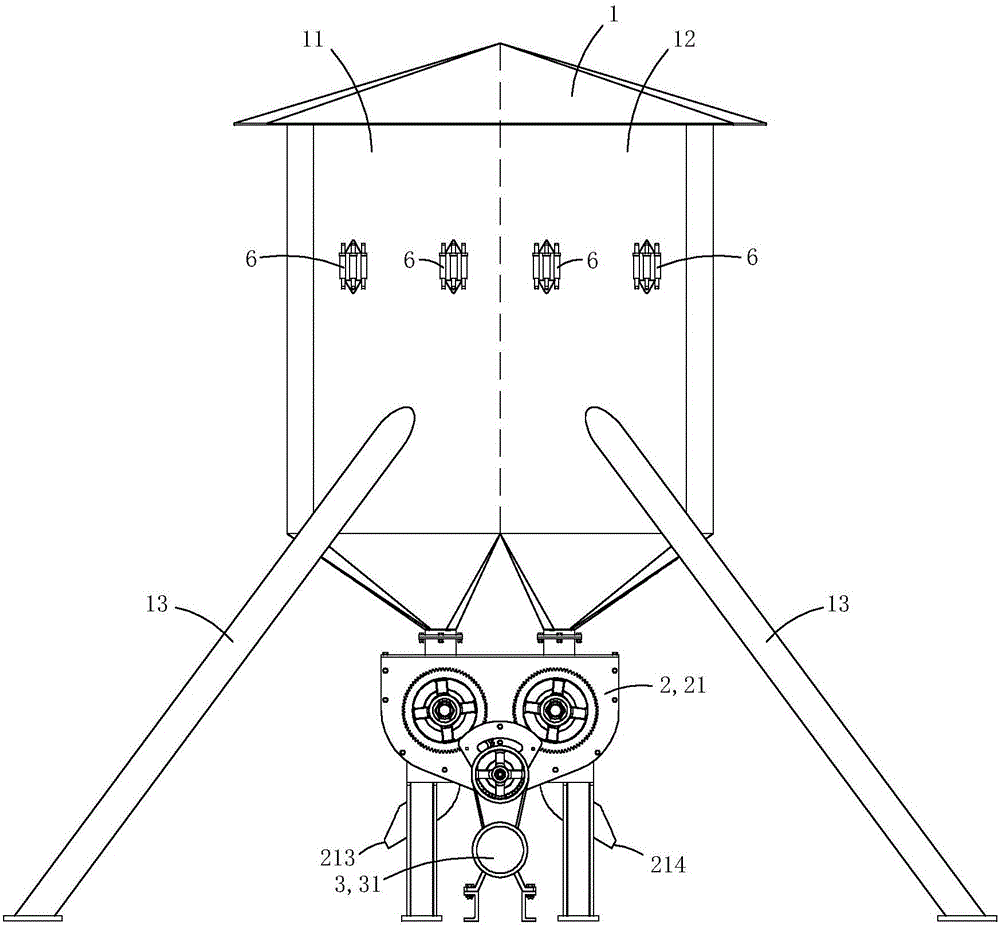

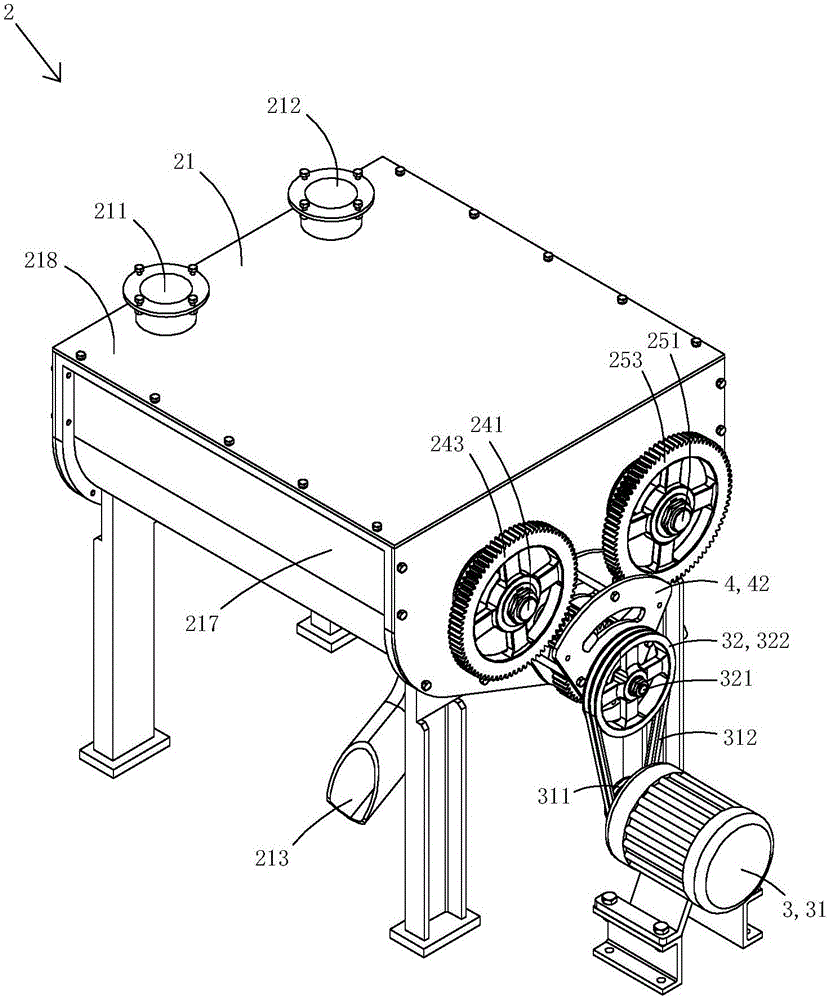

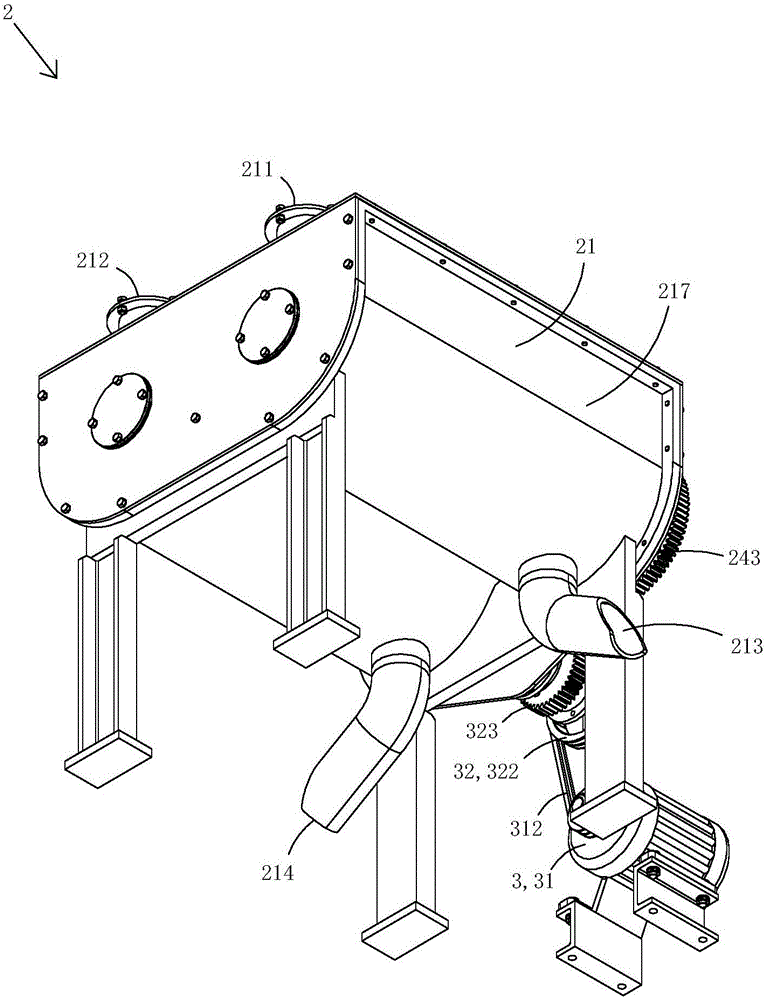

[0034] Figure 1 to Figure 17 A first embodiment of the invention is shown.

[0035] This embodiment is an electric grain unloading granary with real-time monitoring function for grain storage, see Figure 1 to Figure 10 Shown, comprise double-body warehouse 1 and be arranged on the grain unloading device 2 below double-body warehouse.

[0036] The double-body warehouse 1 has a first warehouse 11 and a second warehouse 12 arranged side by side. The bottom of the first warehouse is conical, and the center of the bottom has a first outlet; the bottom of the second warehouse is also conical, and the bottom of the second warehouse is conical. There is a second outlet in the center. In this embodiment, four supporting pillars 13 are arranged at the lower part of the double-body warehouse, and the double-body warehouse stands on the ground through the four supporting pillars. In practice, it is also possible not to support the pillars, but directly fix the double-body warehouse o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com