Disc brake, brake caliper, and brake rotary lever

一种盘式制动器、转动杆的技术,应用在制动器类型、制动器的部件、轴向上制动器等方向,达到节省结构空间、减少密封面、大应用范围的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

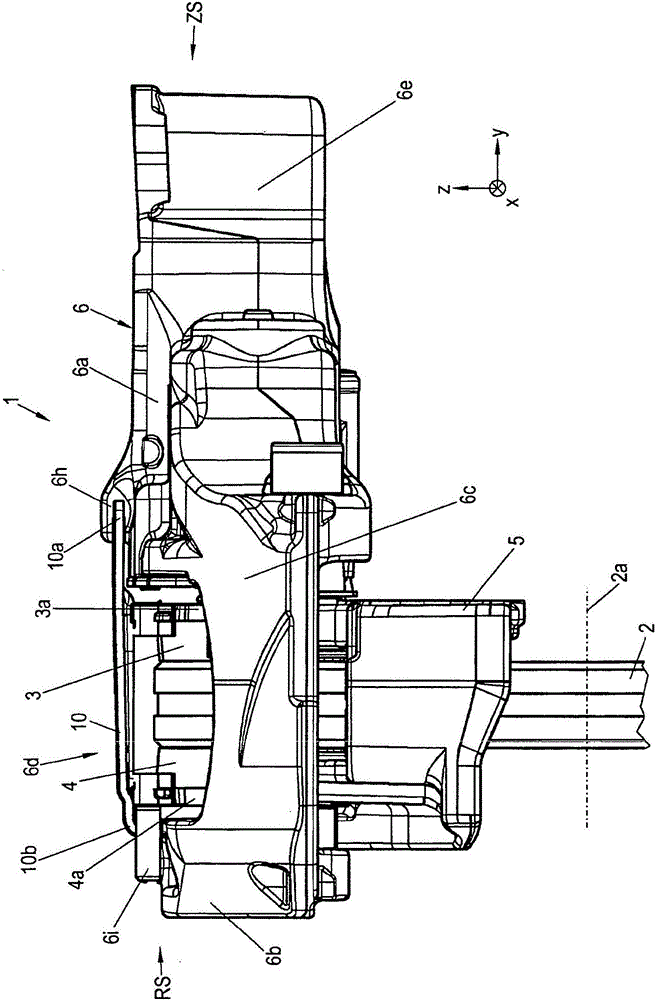

[0047] The coordinates x, y, z in the figures are used to simplify the orientation.

[0048] The contact side of the disc brake 1 is identified with the reference sign ZS, and the rear side of the disc brake 1 is designated with the reference sign RS.

[0049] figure 1 A schematic top view of an exemplary embodiment of a disk brake 1 according to the invention is shown. exist figure 2 shown in the figure 1 A schematic side view of a disc brake 1 according to the invention. image 3 show the basis figure 1 A schematic sectional view of a disc brake 1 according to the invention in the x-y plane.

[0050] Disk brake 1 has a brake disk 2 with a brake disk axis 2a. The brake disk 2 lies in the x-z plane, wherein the brake disk axis 2a extends in the y direction. A pressure-side brake lining 3 with a brake lining carrier 3 a is arranged on the pressure-side side of the brake disk 2 . A further rear brake lining 4 with a brake lining carrier 4 a is arranged on the rear side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com