A magnetron frequency modulation device

A magnetron and guiding device technology, which is applied to the circuit components of magnetrons and transit-time electronic tubes, etc., can solve the problems of uneven five collision points, too long frequency modulation, poor product performance, etc., and achieve improvement. Reliability and performance consistency, preventing cross-linked deformation, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

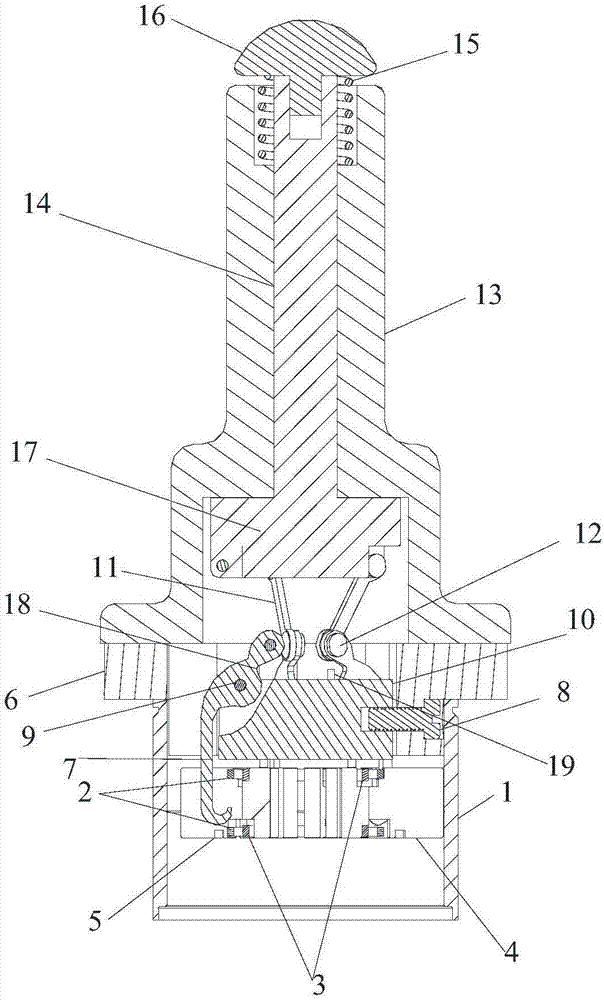

[0041] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the present invention, but can not be used to limit the scope of the present invention.

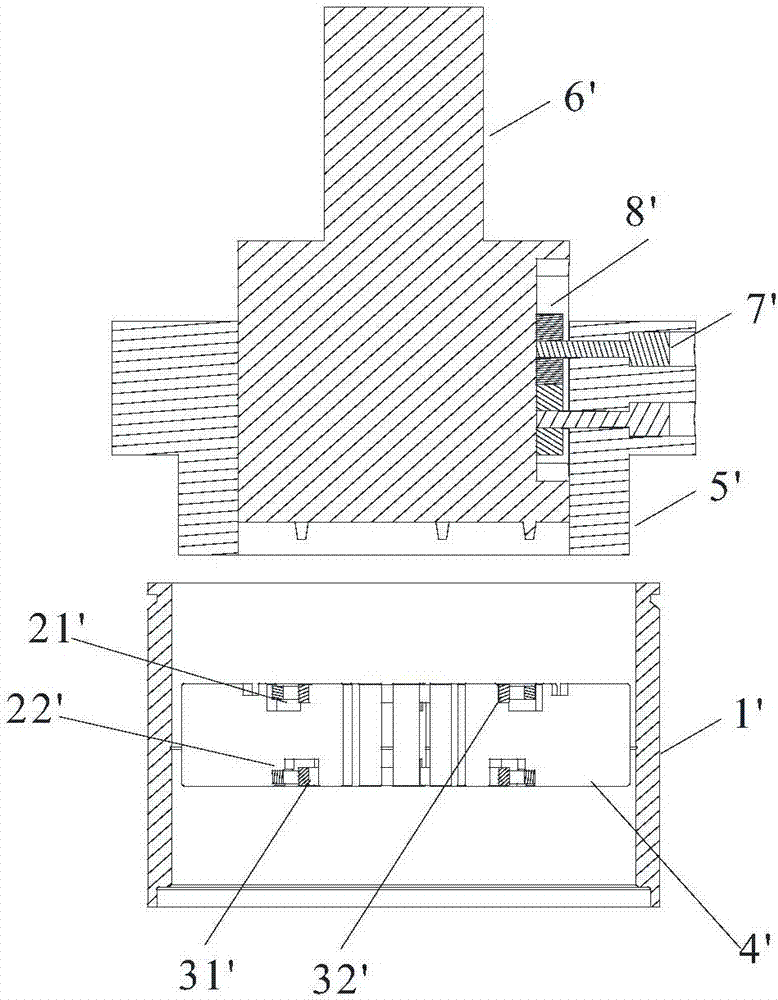

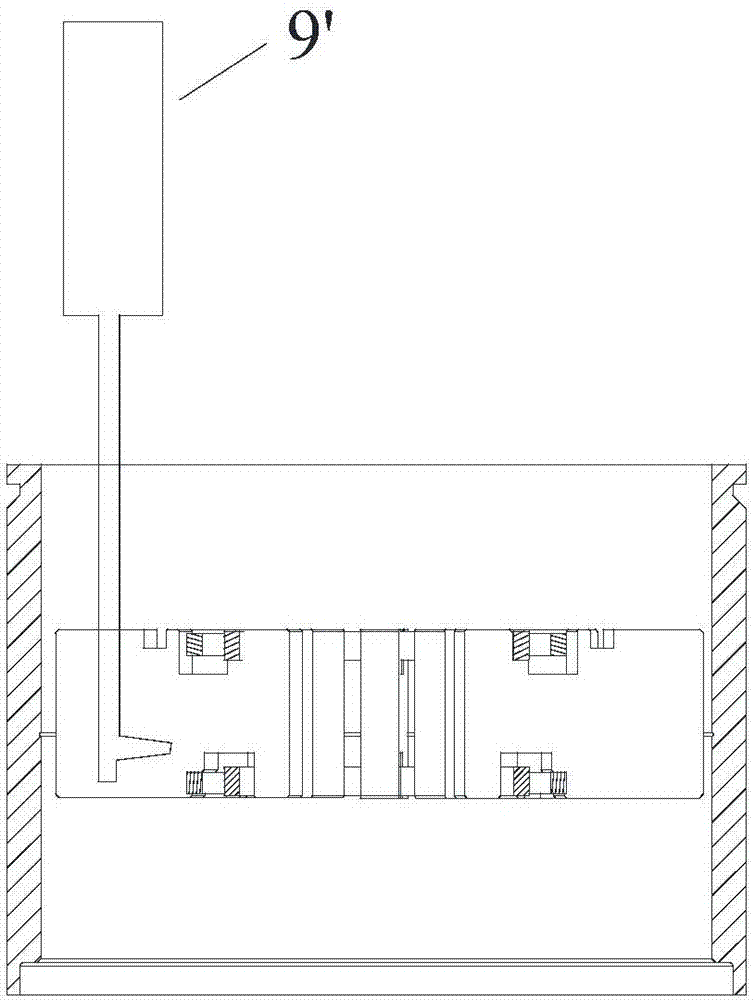

[0042] Such as Figure 3-4 As shown, the magnetron provided by the present invention includes an anode cylinder 1, blades 4 fixed on the inner surface of the anode cylinder 1, and a large cross-link 2, a small cross-link 3 and an antenna groove 5 placed in the anode cylinder, and also provides A magnetron frequency modulation device used in conjunction with it, including a housing 13, a guide device 6, multiple sets of linkage mechanisms 12 uniformly arranged in the circumferential direction and a pressing device 10; the multiple sets of linkage mechanisms 12 are at least 3 sets , so that it can remain stable in the horizontal direction and will not tilt up and down; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com