Light barrier-type 3D liquid crystal display screen and production method thereof

A technology of liquid crystal display and production method, which is applied in the directions of optics, optical components, nonlinear optics, etc., can solve the problems of high cost, large thickness, and different 3D observation effects of 3D touch screens, and achieve good stereoscopic display effects, large thickness, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

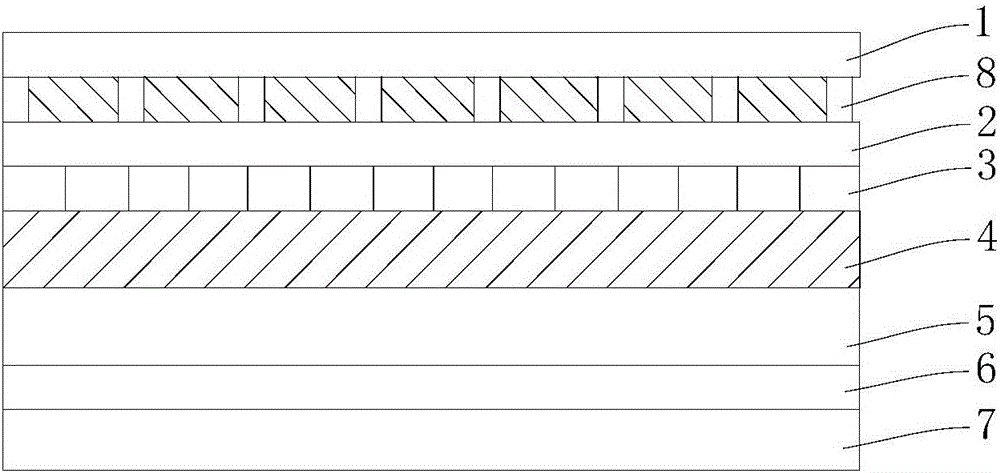

[0040] From top to bottom, the liquid crystal display screen includes an upper polarizer 1, a glass substrate 2 of a color filter, a color filter film 3 of a color filter, a liquid crystal layer 4, a TFT display screen 5, a lower polarizer 6 and a backlight 7. Light and dark stripes 8 for forming a parallax barrier effect are made on the color filter of this embodiment. Specifically include the following steps:

[0041] (1), on the glass substrate 2 of color filter, make the film material that is used to form the bright and dark stripe 8 of parallax barrier effect;

[0042] (2), on the glass substrate 2 of the color filter, make light and dark stripes 8 for forming a parallax barrier effect;

[0043] (3) Attach the color filter with bright and dark stripes 8 to the liquid crystal panel, and then attach the upper polarizer 1 to the color filter.

[0044] In this embodiment, the film material is a photoresist material, and the photoresist material is fabricated on the glass su...

Embodiment 2

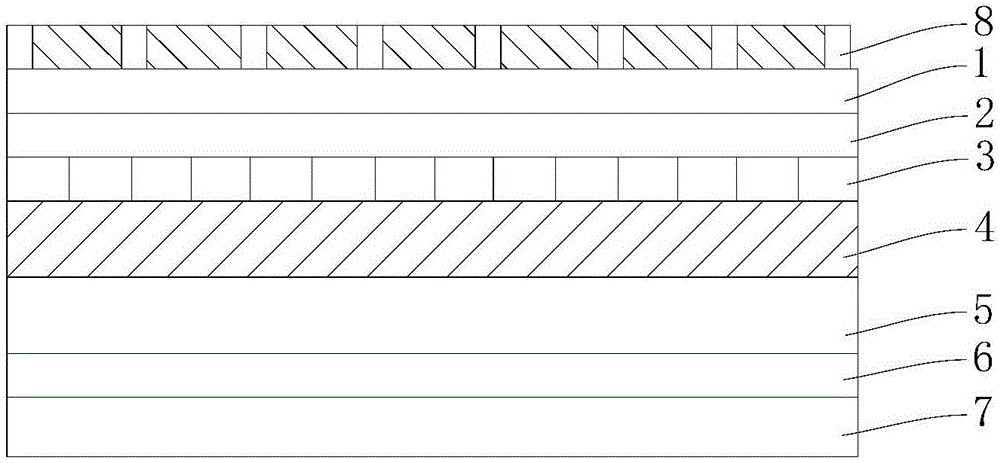

[0049] From top to bottom, the liquid crystal display screen includes an upper polarizer 1, a glass substrate 2 of a color filter, a color filter film 3 of a color filter, a liquid crystal layer 4, a TFT display screen 5, a lower polarizer 6 and a backlight 7. Light and dark stripes 8 for forming a parallax barrier effect are fabricated on the upper polarizer 1 of this embodiment. Specifically include the following steps:

[0050] (1), on the upper polarizer 1, make a film material for forming the light and dark stripes 8 of the parallax barrier effect;

[0051] (2), making light and dark stripes 8 for forming a parallax barrier effect on the upper polarizer 1;

[0052] (3) Attach the upper polarizer 1 with light and dark stripes 8 to the touch module. In other embodiments, the surface of the upper polarizer 1 may also be covered with a layer of organic protective film or cover glass, and then attached to the touch module.

[0053]In this embodiment, the film material is a ...

Embodiment 3

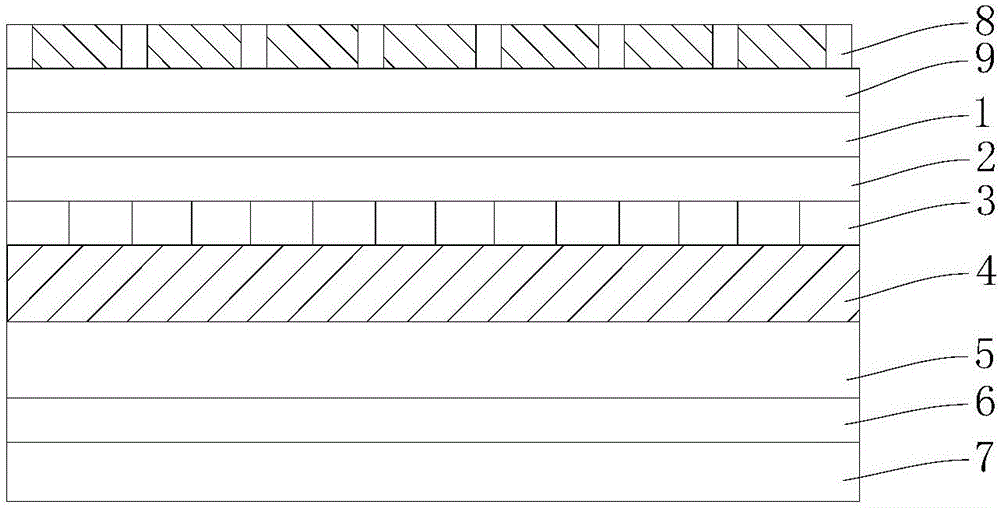

[0058] From top to bottom, the liquid crystal display screen includes an upper polarizer 1, a glass substrate 2 of a color filter, a color filter film 3 of a color filter, a liquid crystal layer 4, a TFT display screen 5, a lower polarizer 6 and a backlight 7. Light and dark stripes 8 for forming a parallax barrier effect are fabricated on the upper polarizer 1 of this embodiment. Specifically include the following steps:

[0059] (1), a layer of photoresist film 9 is attached on the upper polarizer 1;

[0060] (2), making light and dark stripes 8 for forming a parallax barrier effect on the photoresist material film 9;

[0061] (3) Attach the upper polarizer 1 with light and dark stripes 8 to the touch module. In other embodiments, the surface of the upper polarizer 1 may also be covered with a layer of organic protective film or cover glass, and then attached to the touch module.

[0062] In this embodiment, the photoresist film 9 is specifically a polyethylene terephthal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com