Device for reforming fuel at low temperature through exhaust gas residual heat of engine

A low-temperature fuel and engine cylinder technology, which is applied in the direction of fuel heat treatment devices, exhaust devices, engine components, etc., can solve problems such as unsatisfactory energy and the environment, and achieve the effect of broadening the range of efficient and clean combustion and realizing efficient and clean combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

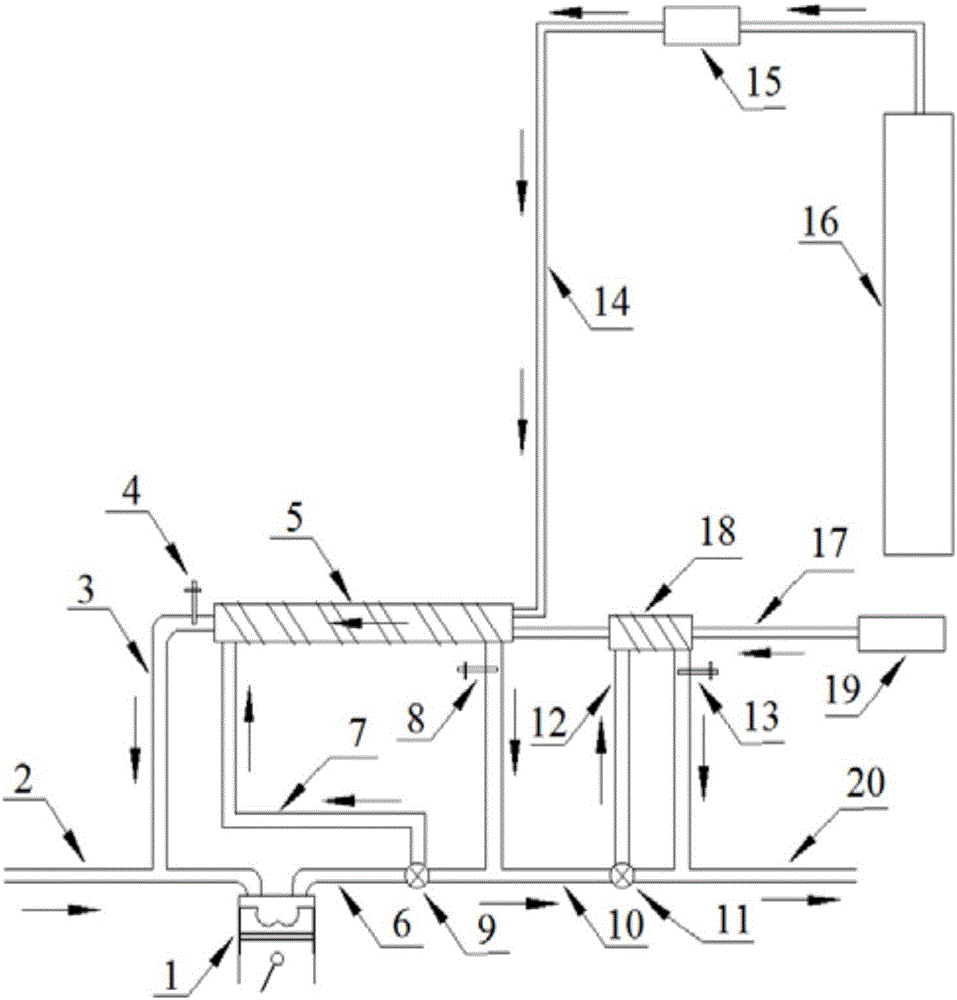

[0016] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

[0017] The invention proposes a device for low-temperature reforming of fuel by using the waste heat of engine exhaust gas to realize low-temperature reforming of fuel, and also realize stratification of mixture gas concentration and active stratification combustion in the engine cylinder, and does not need to add a catalyst, and exhaust gas at the same time The waste heat of the pipe exhaust is also effectively utilized, resulting in a more efficient and energy-efficient operation of the engine. The invention is based on the low-temperature reforming method of engine fuel, and consists of two parts: an external low-temperature fuel reformer and an engine main body.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com