High-pressure exhaust gas recirculation (EGR) system of vehicle engine

An engine and vehicle technology, applied in the field of EGR system, can solve the problems of large diameter of EGR mixed gas circulation pipeline, increase the difficulty and cost of layout, increase the failure of EGR valve, etc. The effect of fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

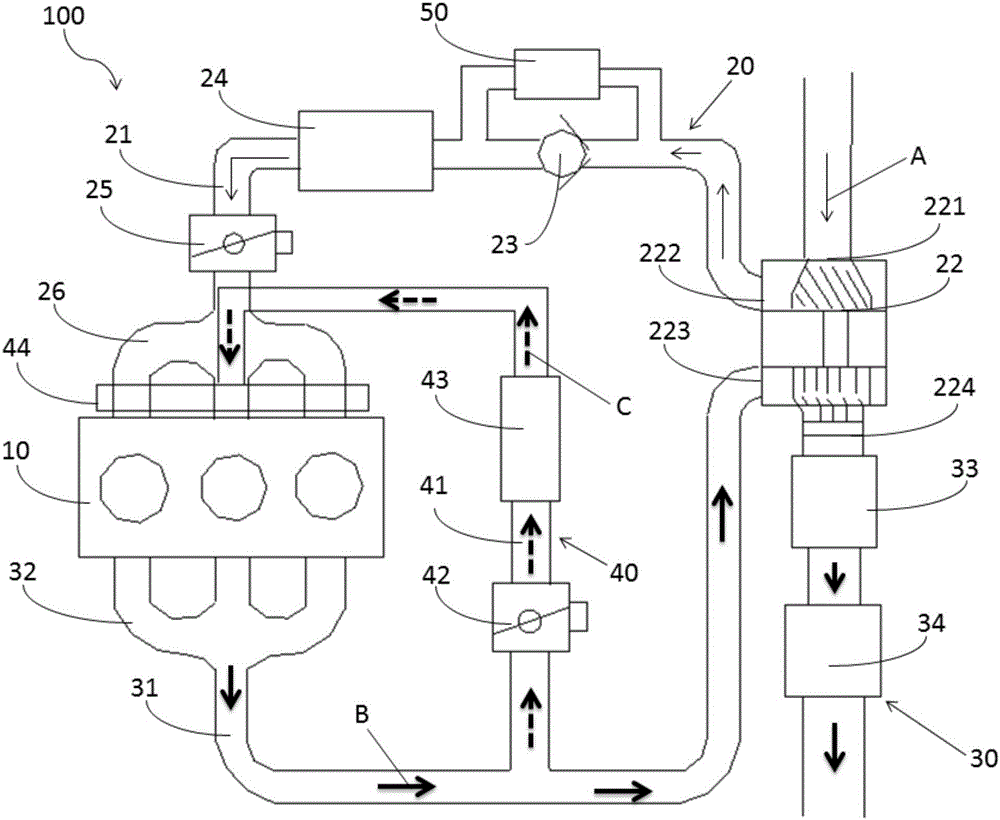

[0026] figure 1 It is a structural schematic diagram of a high-pressure EGR system of a supercharged gasoline engine according to an embodiment of the present invention.

[0027] In particular, see figure 1 , the present invention provides a high-pressure EGR system 100 for a vehicle engine, passing through an engine 10, wherein the engine 10 has an intake port and an exhaust port. The high-pressure EGR system 100 of the vehicle engine may include an intake pipeline 20 , an exhaust pipeline 30 , an EGR pipeline 40 and an electronic supercharger 50 . Wherein, the air intake pipeline 20 is arranged before the air intake port for gas inflow of the engine 10 . The exhaust pipeline 30 is arranged behind the exhaust port, and is used for exhaust gas of the engine 10 to be discharged. The EGR pipeline 40 is connected between the intake port of the engine 10 and the exhaust pipeline 30, and is used to recirculate part of the exhaust gas discharged from the exhaust pipeline 30 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com