A fixed installation structure and method for a profiled steel plate composite floor insulation board

A technology of profiled steel plates and combined floor slabs, which is applied in the directions of heat preservation, building components, building structures, etc., can solve the problems of reliable fixation, low construction efficiency, falling off, etc., and achieves the effects of stable and firm fixation, simple structure and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

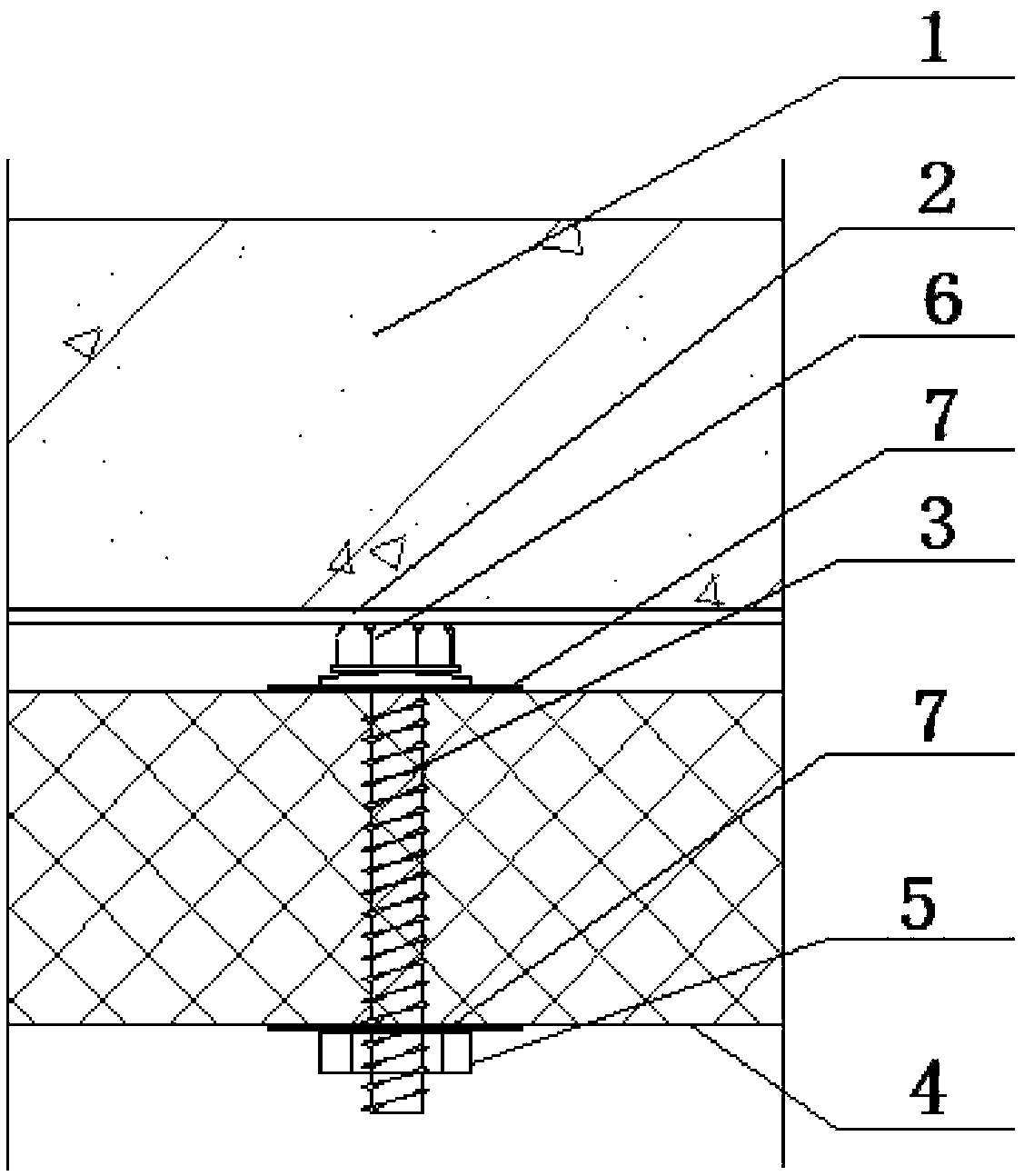

[0034] Such as figure 1 As shown, the present invention includes a concrete wallboard 1, one side of the concrete wallboard 1 is fixedly connected to one side of a profiled steel plate 2, and a plurality of screw rods are fixed on the side of the profiled steel plate 2 away from the concrete wallboard 1 3. One end of the screw 3 is fixedly connected to the profiled steel plate 2 by welding, and the other end of the screw 3 passes through the insulation board 4 and is locked and fixed by a nut 5 .

[0035] One end of the screw 3 is provided with a screw head 6 , and the end surface of the screw head 6 is fixedly connected with the profiled steel plate 2 . Gaskets 7 are provided between the screw head 6 and the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com