Automatic single piece cutting machine

A technology of automatic cutting and single-chip microcomputer is applied in the field of fabric processing and forming, which can solve the problems of personal error, low work efficiency and large operation error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

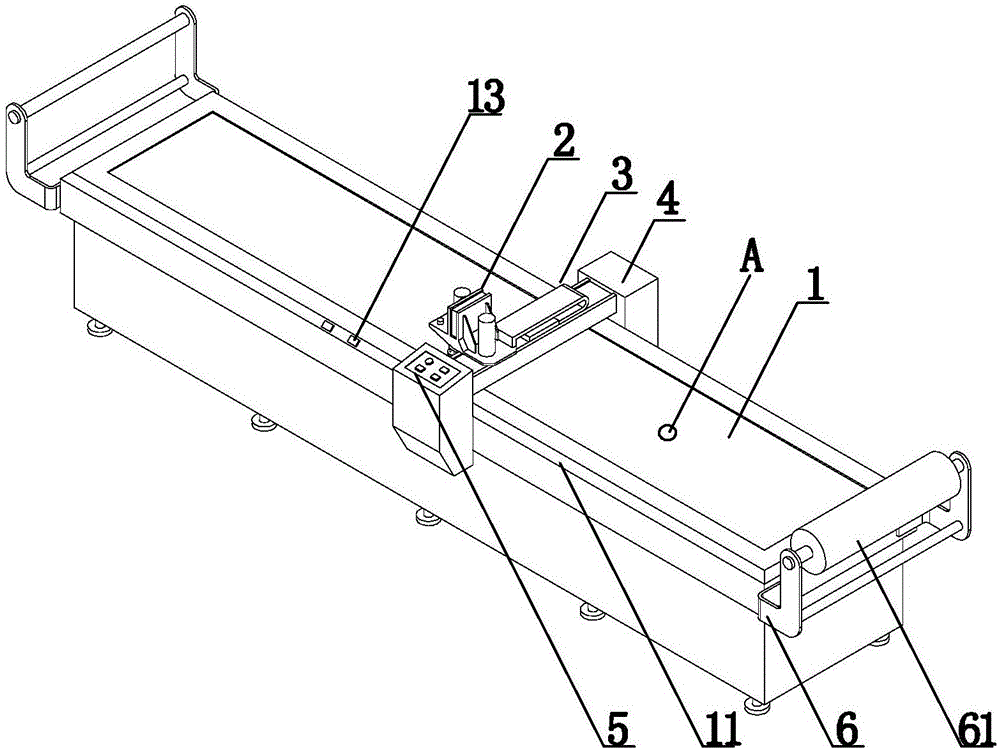

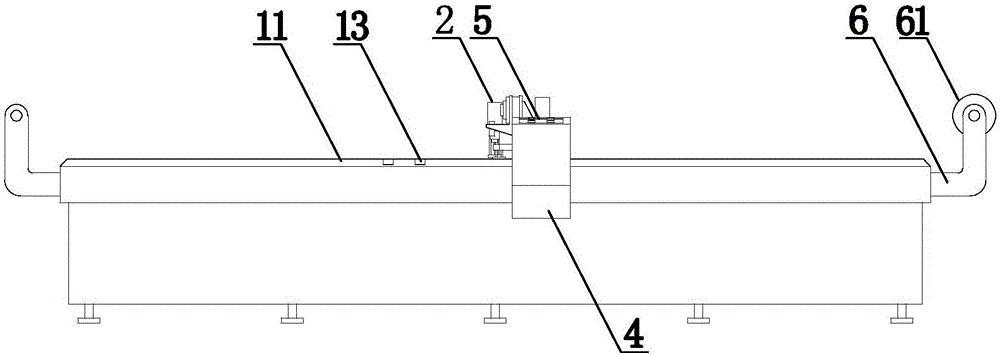

[0019] This embodiment cuts the single-chip microcomputer automatically, combines figure 1 , figure 2 , image 3 and Figure 4 , including workbench 1, cutting head 2, track 3, track frame 4 and controller 5, track frame 4 is a C-shaped structure, fastened on workbench 1, and track 3 passes through the track The frame 4 is erected on the workbench 1, the track frame 4 and the track 3 are respectively connected with the controller 5, and the controller 5 drives the track frame 4 to move back and forth along the workbench 1 (that is, to move along the length direction of the workbench 1), and the controller 5 The drive track 3 moves left and right on the track frame 4, the cutting head 2 is connected with the track 3, and moves with the movement of the track 3, and the movement of the track frame 4 and the track 3 jointly realizes the movement of the cutting head 2 position; the cutting head 2 Driven by the driving source to move up and down, the cutting head 2 realizes cutt...

Embodiment 2

[0023] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that: a side beam 11 is arranged on the periphery of the workbench 1, and the track frame 4 is erected on the side beam 11 in its length direction, and under the drive of the controller 5, Move back and forth along the side beam 11. The side beam 11 of the workbench 1 provides a point of force for the track frame 4, and fixes the moving track of the track frame 4, avoiding the dislocation caused by the excessive movement of the track frame 4, and effectively ensuring the movement accuracy.

Embodiment 3

[0025] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that: a side beam 11 is arranged on the periphery of the workbench 1, and the track frame 4 is erected on the side beam 11 in its length direction, and under the drive of the controller 5, Move back and forth along the side beam 11; the side beam 11 is provided with a return switch 13, the return switch 13 is connected with the controller 5, when the cutting is completed, start the return switch 13, the controller 5 drives the track frame 4 and the Track 3 and cutting head 2 reset, waiting for the next operation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com