Inner-barrel back cover for dry washers and manufacturing method of inner-barrel back cover

A manufacturing method and technology of a dry cleaning machine, applied to other washing machines, applications, washing devices, etc., can solve the problems of easy generation of waste products, poor surface quality, etc., and achieve the effects of ensuring quality, improving service life, and ensuring surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

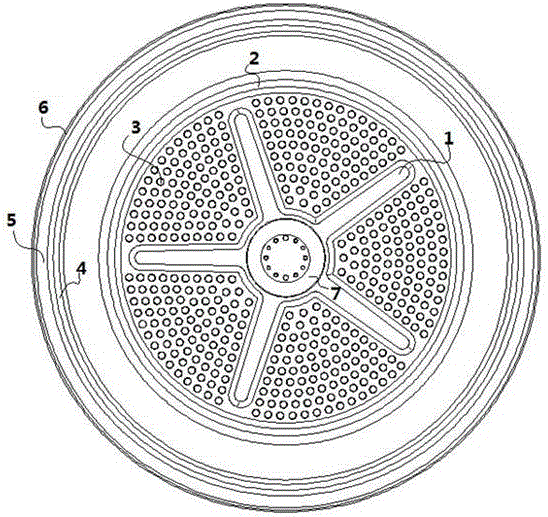

[0037] Such as figure 1As shown, the back cover of an inner tube used for a dry cleaning machine in this embodiment includes a disc-shaped body, a flanging 6 is provided on the outer circumference of the disc-shaped body, and an annular protrusion II7 is provided at the center of the disc-shaped body. , and there are more than three long protrusions 1 uniformly distributed around the protrusion II7, and the long protrusions 1 extend to the groove I2 along the radial direction of the disc-shaped body, and two adjacent long protrusions 1 There are the same number of drainage holes 3 arranged in the same arrangement, and more than 8 rows of drainage holes 3 are arranged between two adjacent strip protrusions 1 and along the radial direction of the disk-shaped body, and the drainage holes 3 located in the same row The holes 3 are located on the same circumference, and the long protrusion 1, the protrusion I5 and the protrusion II7 are all protrusions with a circular arc surface. S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com