Anti-water breakthrough material for well cementation and preparation method thereof

A technology of cementing and inorganic materials, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems affecting the cement slurry solidification process, destroying the cement sheath structure and cementation quality, and shorten the static gelation transition time , Improve the ability of water intrusion resistance and water channeling, and avoid the effect of pressure instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

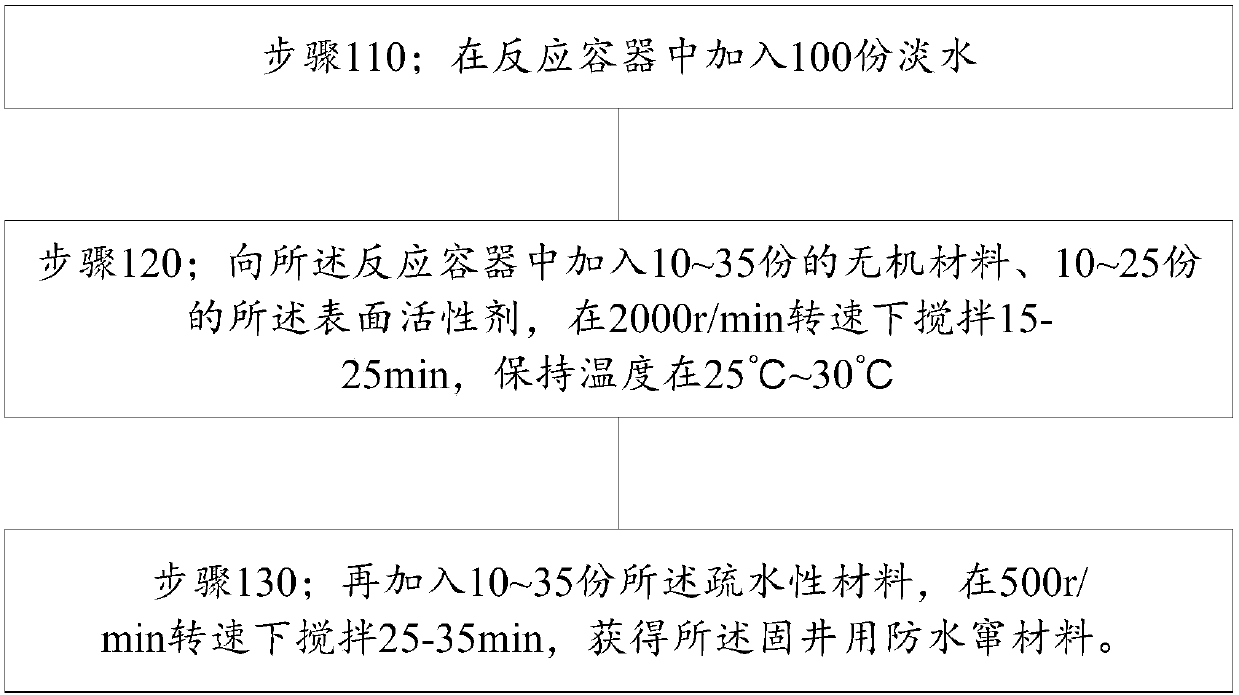

[0027] Such as figure 1 As shown, it is a flow chart of the preparation method of the waterproof channeling material for well cementing, and the preparation method includes:

[0028] Step 110: Add 100 parts of fresh water into the reaction vessel.

[0029] Step 120: Add 10-35 parts of inorganic materials and 10-25 parts of the surfactant into the reaction vessel, stir at 2000r / min for 15-25min, and keep the temperature at 25°C-30°C.

[0030] Specifically, the reaction at a rotational speed of 2000r / min for 15-25min is specifically: reacting at a rotational speed of 2000r / min for 20min.

[0031] Step 130: Add 10-35 parts of the hydrophobic material, and stir at 500 r / min for 25-35 minutes to obtain the waterproof material for cementing.

[0032] Specifically, the said stirring at 500r / min rotation speed for 25-35min is specifically: reacting at 500r / min rotation speed for 20min.

[0033] The beneficial effects of this application are as follows:

[0034] (1) Organically com...

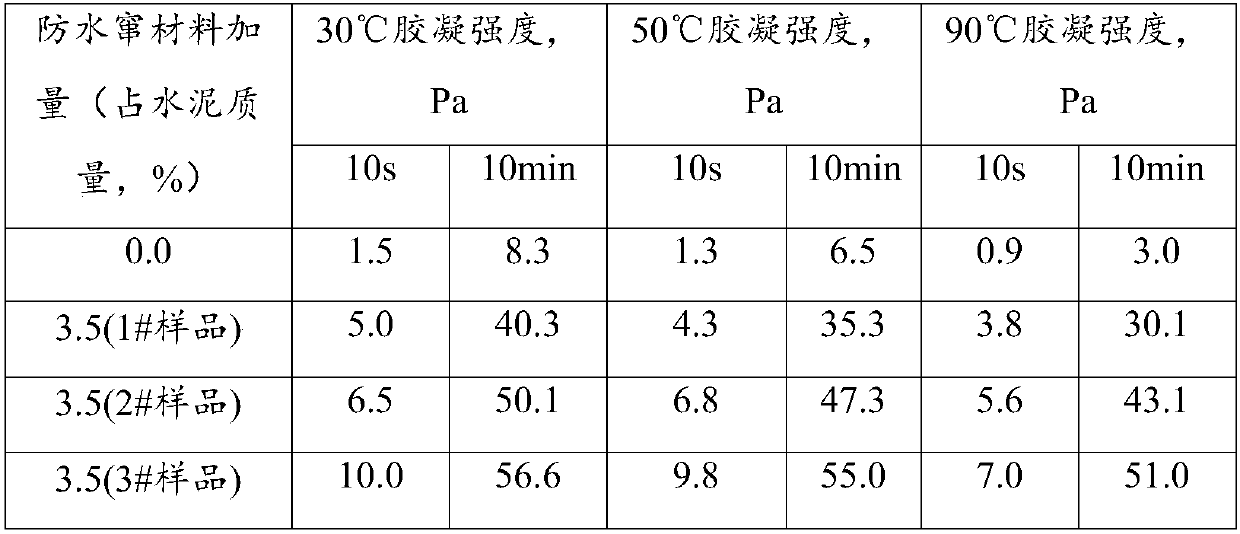

Embodiment 1

[0040] Weigh 100 parts of fresh water, put it into a container with a stirrer, then weigh 15 parts of inorganic thixotropic material and 20 parts of surfactant, cover the container, turn on the stirrer, and keep the temperature at 25°C to 30°C , reacted at 2000r / min for 20min; then added 25 parts of hydrophobic materials, 15 parts of expansion agent and 15 parts of inorganic salt, stirred at 500r / min for 30min and mixed evenly to obtain viscous liquid waterproof Material, marked as 1# sample.

Embodiment 2

[0042] Weigh 100 parts of fresh water, put it into a container with a stirrer, then weigh 20 parts of inorganic thixotropic material and 15 parts of surfactant, cover the container, turn on the stirrer, and keep the temperature at 25°C to 30°C , react at 2000r / min for 20min; then add 20 parts of hydrophobic material, 10 parts of expansion agent and 15 parts of inorganic salt, stir at 500r / min for 30min and mix evenly to get viscous liquid waterproof Material, marked as 2# sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com