A kind of opacity glaze and preparation method thereof

A technology of opaque glaze and glaze powder, applied in chemical instruments and methods, titanium compounds, alkaline earth metal titanates, etc., can solve the problems of scarcity of resources, high cost, high temperature viscosity of opaque glaze, etc., and achieve opacity effect Good, easy to operate, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

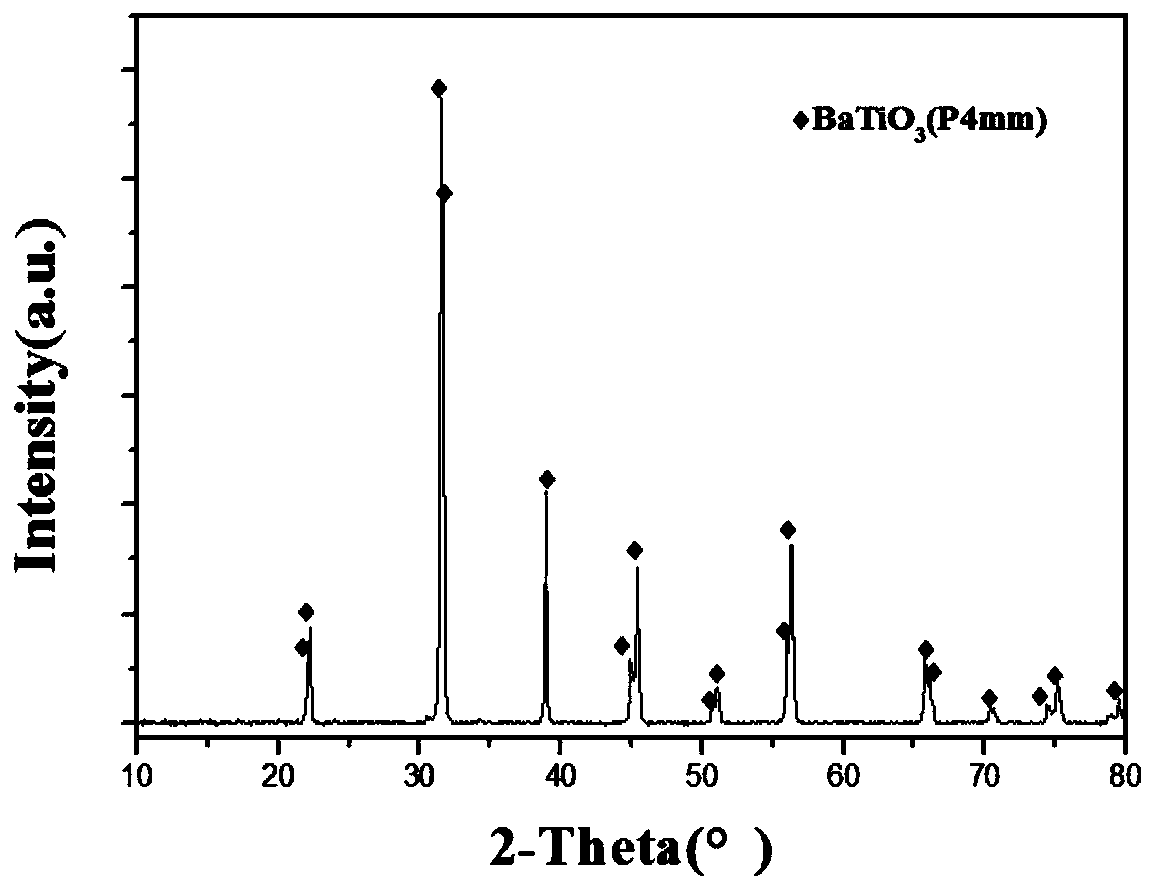

Image

Examples

Embodiment 1

[0025] Prepare a kind of opacity glaze, concrete method is as follows:

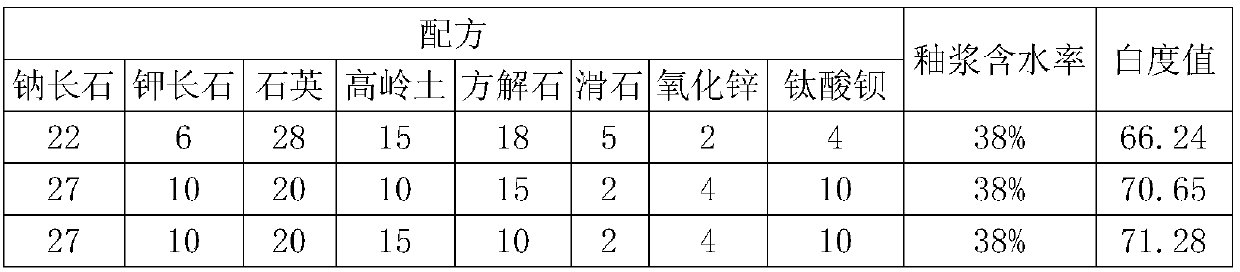

[0026] 1) Prepare glaze powder: weigh each raw material one by one according to the formula data in Table 1;

[0027] 2) Preparation of opacified glaze: put the glaze powder obtained in step 1) with ball stones and water in a mass ratio of 1:2:0.6 in a rapid mill and ball mill until the fineness is less than 0.1 wt% after passing through a 250 mesh sieve, and the obtained The glaze slurry is opacified glaze. The specific experimental formula and test results are shown in Table 1 below:

[0028] Table 1

[0029]

[0030] Apply the opacified glaze obtained in this example on the ceramic green body by dipping the glaze. The thickness of the glaze is 1.0 mm. After the glaze is dried, it is fired in a roller kiln. After the kiln is cooled, high white opacity ceramics are obtained, and the entire firing cycle is about 60-70 minutes. The glazed surface of the tiles fired in the above-mentioned manner has ...

Embodiment 2

[0032] Prepare two opacifying glazes, the specific method is as follows:

[0033] 1) Preparation of glaze powder: Weigh the following materials in parts by weight: 26 parts of albite, 6 parts of potassium feldspar, 30 parts of quartz, 15 parts of calcite, 10 parts of kaolin, 6 parts of potassium feldspar, barium titanate (the (2) 8 parts of zirconium silicate instead of barium titanate), 3 parts of talc, 2 parts of zinc oxide, and mix the weighed materials evenly to obtain glaze powder;

[0034] 2) Preparation of opacified glaze: put the glaze powder obtained in step 1) with ball stones and water in a mass ratio of 1:2:0.6 in a rapid mill and ball mill until the fineness is less than 0.1 wt% after passing through a 250 mesh sieve, and the obtained The glaze slurry is opacified glaze, and the water content of the glaze slurry is 38%.

[0035] 3) The specific experimental data and results are shown in Table 2 below:

[0036] Table 2

[0037]

[0038]

[0039] The two ki...

Embodiment 3

[0041] Prepare a kind of opacity glaze, concrete method is as follows:

[0042] 1) Preparation of glaze powder: Weigh the following materials in parts by weight: 26 parts of albite, 6 parts of potassium feldspar, 26 parts of quartz, 15 parts of calcite, 12 parts of kaolin, 6 parts of potassium feldspar, and 8 parts of barium titanate , 3 parts of talc, 4 parts of zinc oxide, and mix the weighed materials evenly to obtain glaze powder;

[0043]2) Preparation of opacified glaze: put the glaze powder obtained in step 1) with ball stones and water in a mass ratio of 1:2:0.6 in a rapid mill and ball mill until the fineness is less than 0.1 wt% after passing through a 250 mesh sieve, and the obtained The glaze slurry is opacified glaze. The specific experimental data and results are shown in Table 3 below:

[0044] table 3

[0045]

[0046] Apply the opacified glaze obtained in this example on the ceramic green body by spraying glaze, the glaze thickness is 1.0mm, after the gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com