Air-cylinder mobile-type cosmetic raw material kit moving mechanism

A technology for moving mechanisms and cosmetics, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of low efficiency, poor effect, trouble, etc., and achieve the effect of high efficiency, stable handling and good handling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

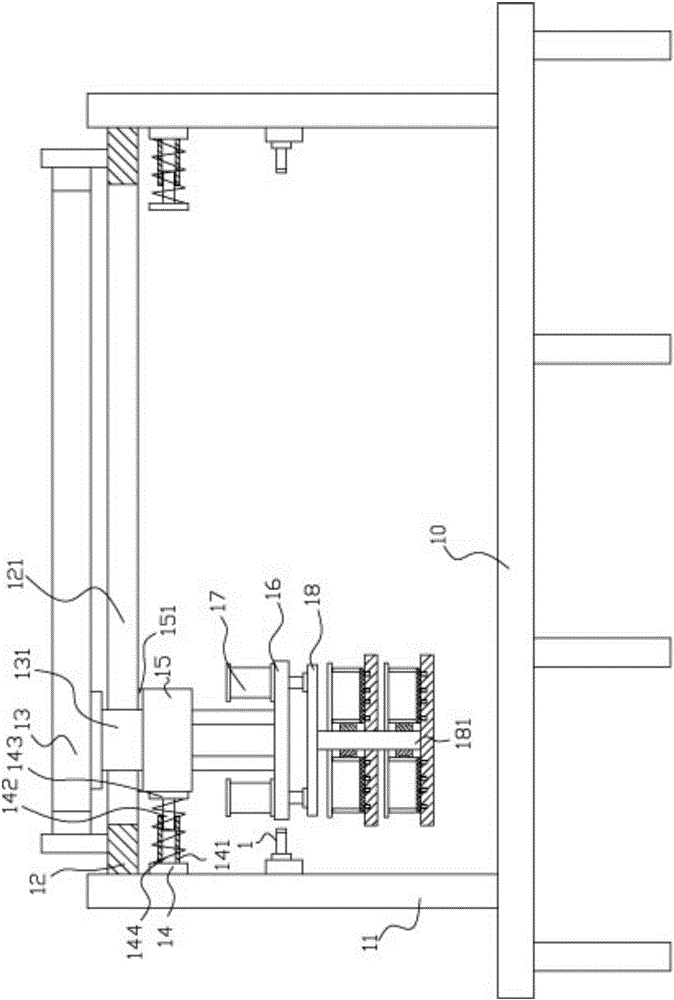

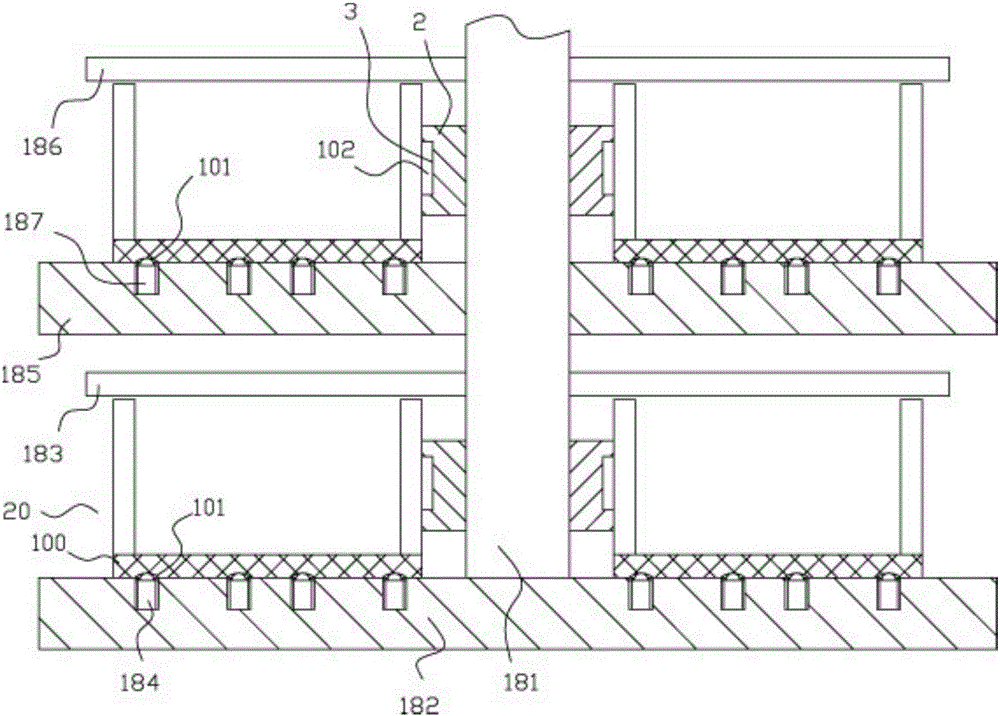

[0021] Example: see Figure 1 to Figure 2 As shown, a cylinder moving type cosmetic raw material kit moving mechanism includes an operating table 10, vertical supporting plates 11 are fixed on both sides of the top plate of the operating table 10, and the upper supporting plate 12 is fixed on two vertical supporting plates 11, the top surface of the upper support plate 12 is fixed with a mobile rodless cylinder 13, and the push plate of the mobile rodless cylinder 13 is fixed with a sliding block 131, and the sliding block 131 is inserted into the horizontal through groove 121 provided on the upper support plate 12. Among them, the bottom surface of the sliding block 131 is fixed with a moving block 15;

[0022] The bottom surface of the moving block 15 is fixed with a cylinder frame 16, and the top surface of both sides of the bottom plate of the cylinder frame 16 is fixed with a telescopic cylinder 17, and the push rod of the telescopic cylinder 17 passes vertically downward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com