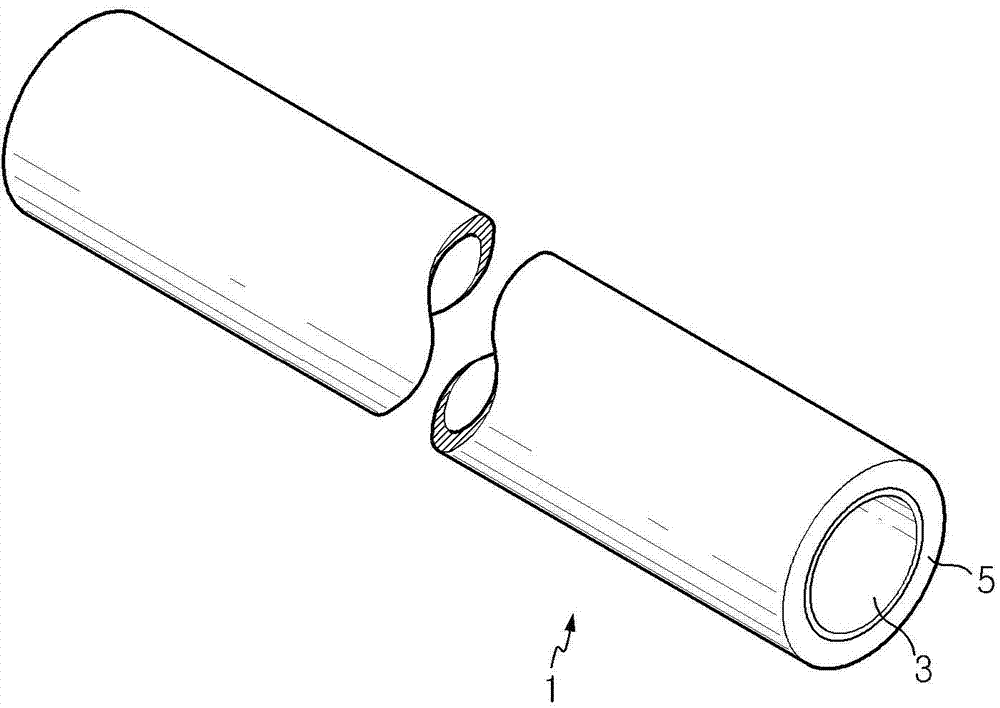

Composite pipe with metal pipe coated by resin, and manufacturing method and construction method thereof

A metal composite pipe and a manufacturing method technology, which are applied in the directions of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve problems such as poor surface of the composite pipe 1, and achieve the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] specific implementation plan

[0062] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. Prior to this, the terms or words used in this specification and claims should not be interpreted as the general or dictionary-defined meaning, but from the concept that the inventor properly defines the term in the best way to describe his invention. From a perspective, it is interpreted as the meaning and concept in line with the technical concept of the present invention. Therefore, the embodiments described in this specification and the structures illustrated in the drawings are only embodiments of the present invention and cannot fully express the technical concept of the present invention. It should be understood that various alternatives to these embodiments may be included when applying Equivalent schemes and variant schemes.

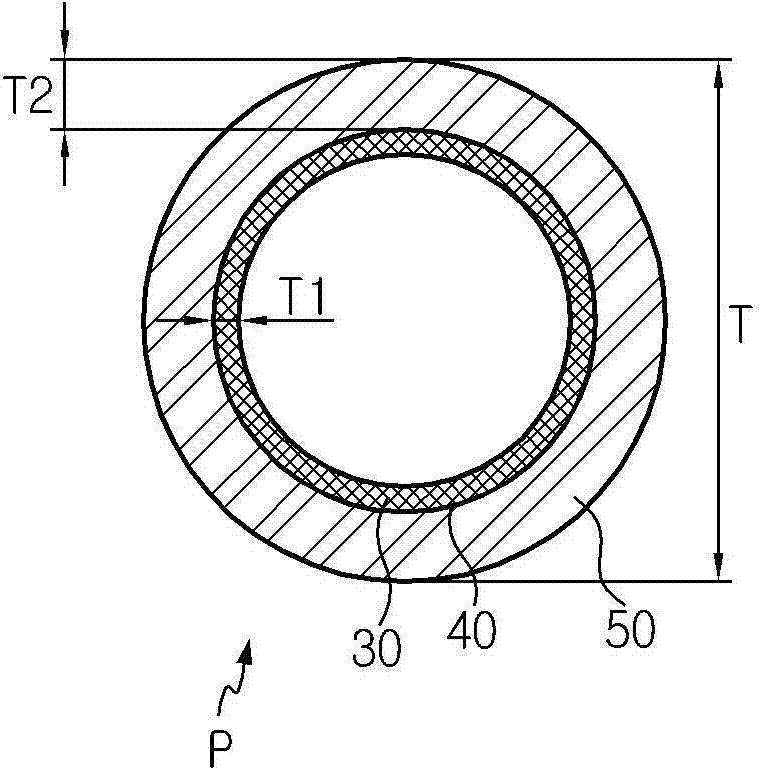

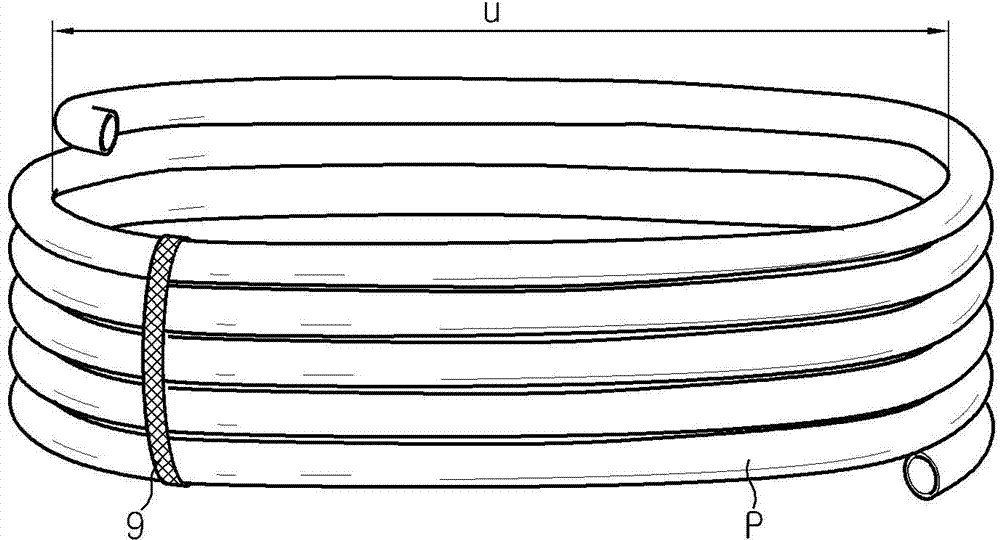

[0063] figure 2 is a cross-sectional view of a resin-metal composite pipe according to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com