Use method of feed transmission mechanism for semi-finished aluminum ingots

A conveying mechanism and semi-finished product technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as slippage, damage to aluminum ingots, and reduce production efficiency, achieve uniform efficiency, reduce load capacity, and improve feeding. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

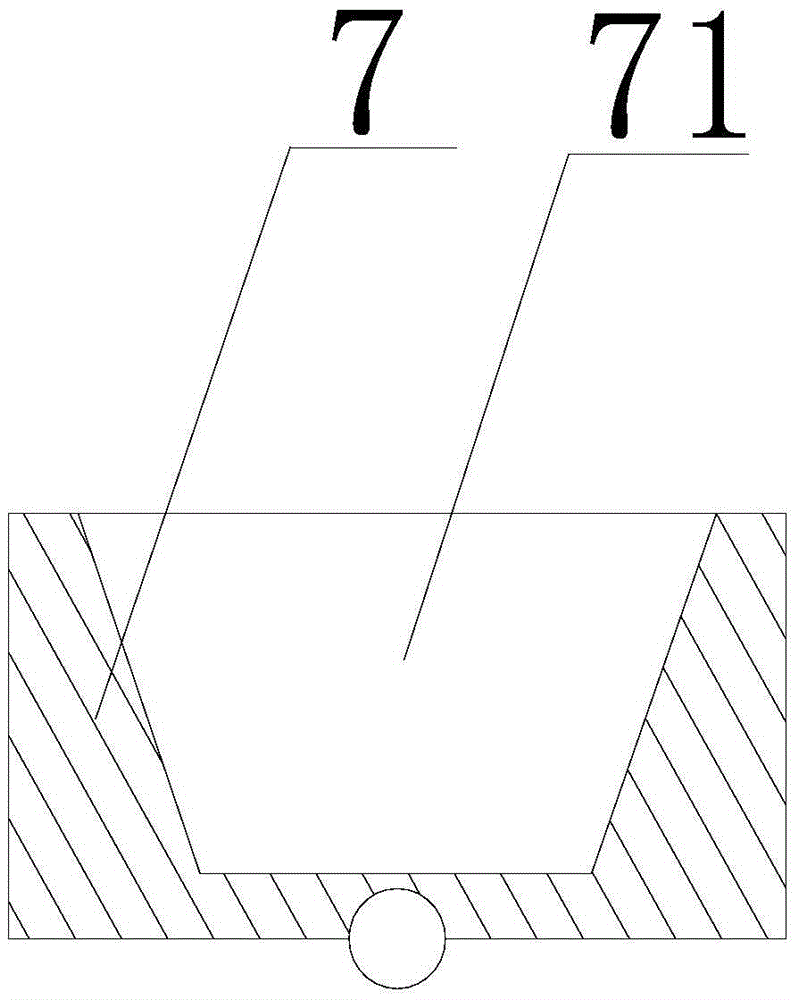

[0025] Such as figure 1 and figure 2 As shown, this embodiment includes the following steps:

[0026] A. Put the semi-finished aluminum ingots produced into the hopper, and the surroundings of the aluminum ingots are in direct contact with the inner wall of the containing chamber. The aluminum ingots use their own gravity to squeeze the inner wall of the containing chamber, thereby ensuring the stability and safety of the aluminum ingots;

[0027] B Start the motor to drive the main roller to run, and the slave roller and the main roller are used together;

[0028] C The conveyor chain plate moves continuously from the roller to the direction of the main roller, and the hopper corresponds to the aluminum ingot one by one. When the hopper moves to the part of the conveyor chain plate facing the roller, the hopper turns over, and then the aluminum ingot is realized. transmission feed;

[0029] The above steps include two U-shaped support seats 3 and the transmission chain pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com