Cotton swab packing machine

A cotton swab packaging, cotton swab technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of single packaging quantity and specifications, cotton swabs are easily polluted, and packaging efficiency is low, and achieve stable and reliable transfer, ingenious structural design, and packaging. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

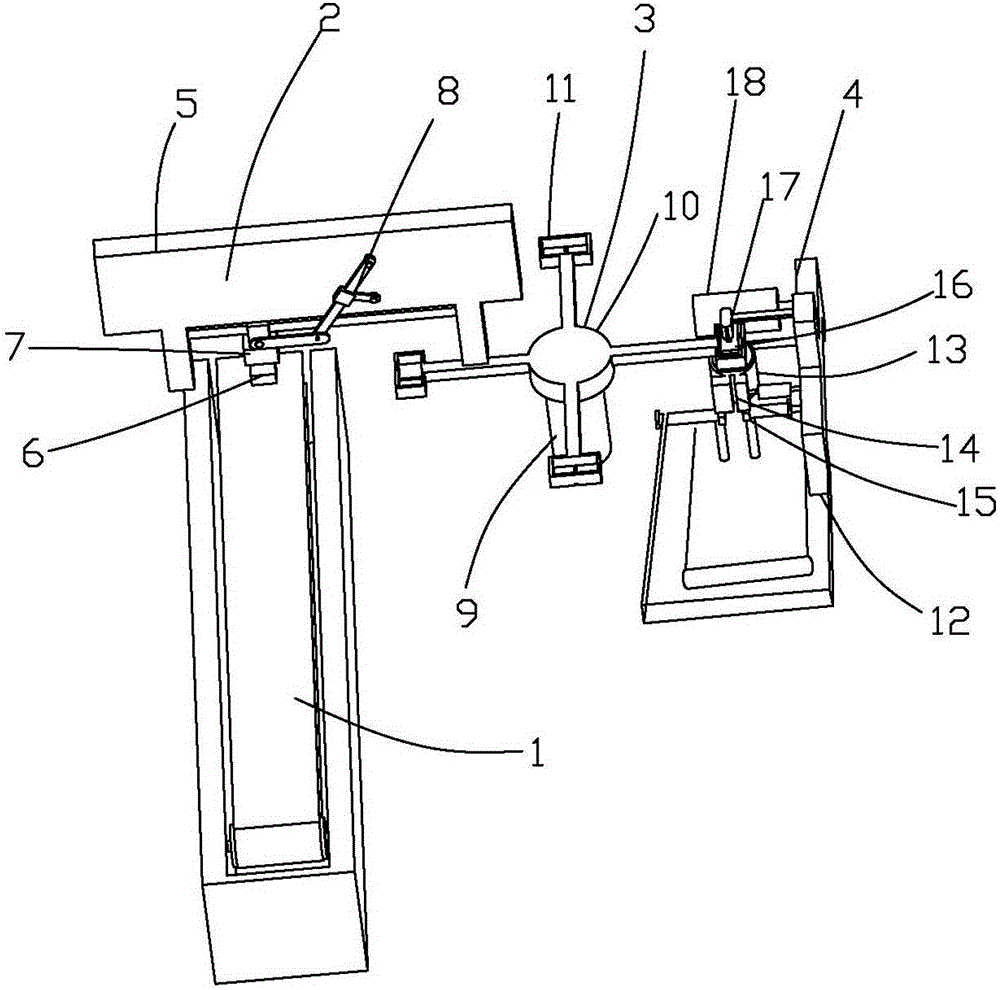

[0022] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Depend on Figure 1 to Figure 4 Given, the present invention includes a cotton swab conveying device that conveys cotton swabs neatly arranged at intervals, an adsorption device 2 arranged above the tail of the conveying device 1, a transfer device 3, and a packaging device 4, and is characterized in that,

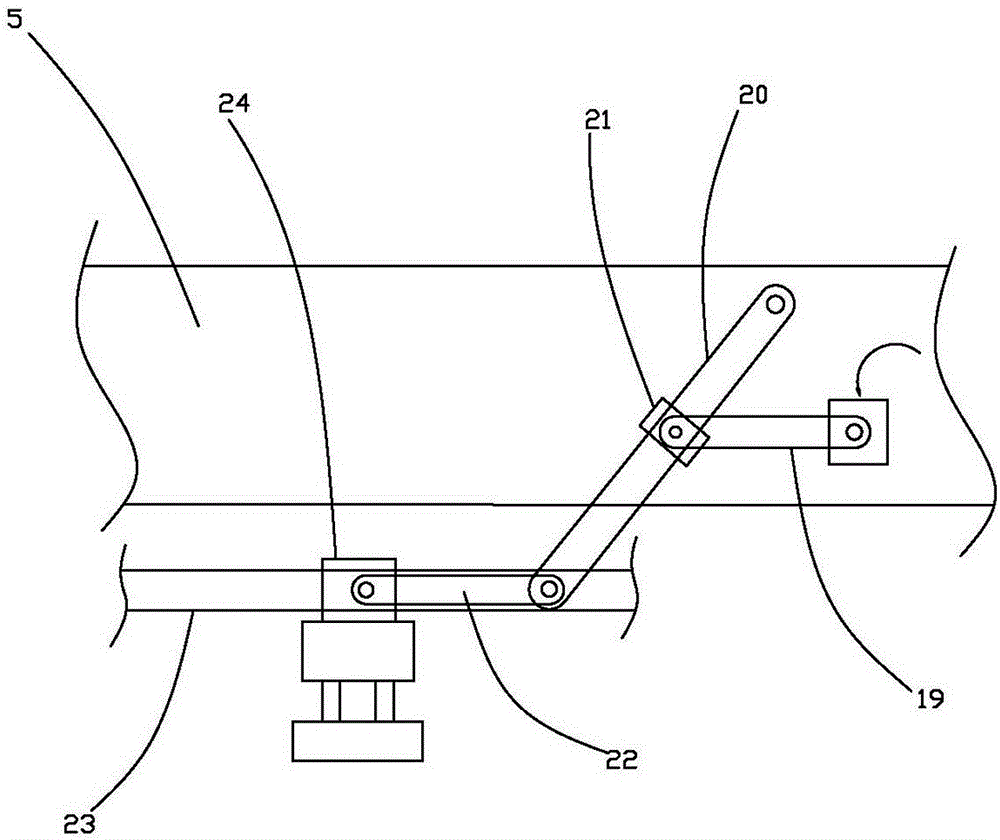

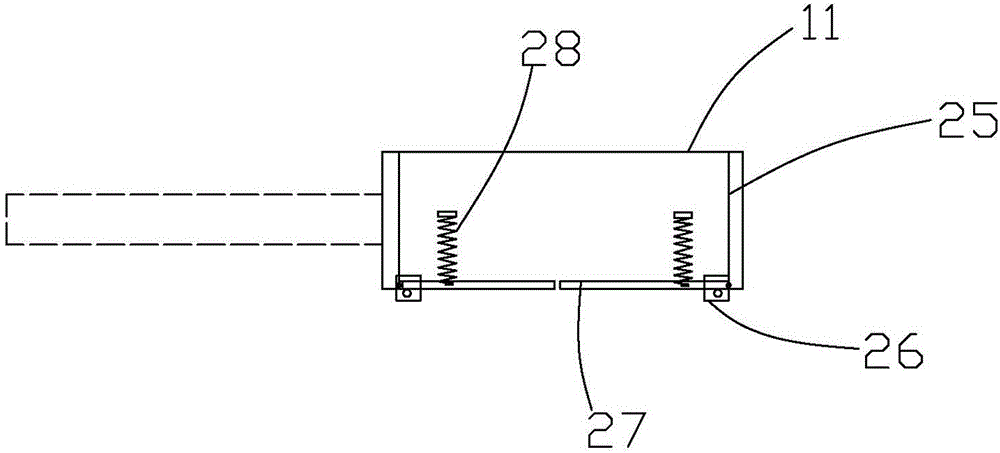

[0024] The adsorption device 2 includes a support plate 5 fixed on the tail of the conveying device, a vacuum suction cup 6, a lifting cylinder 7 for driving the vacuum suction cup to move up and down, a translation mechanism 8 for driving the lifting cylinder 7 and the vacuum suction cup 6 to move horizontally, The lifting cylinder 7 is connected to the top of the vacuum chuck 6, and the translation mechanism 8 is connected to the lifting cylinder 7, and the translation mechanism 8 is installed on the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com