Bamboo wood dipping technology for reducing bamboo kun loss

A technology, bamboo kun technology, applied in wood processing equipment, coating impregnation, wood heating, etc., can solve problems such as low efficiency, serious environmental pollution of residual liquid, and difficulty in large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

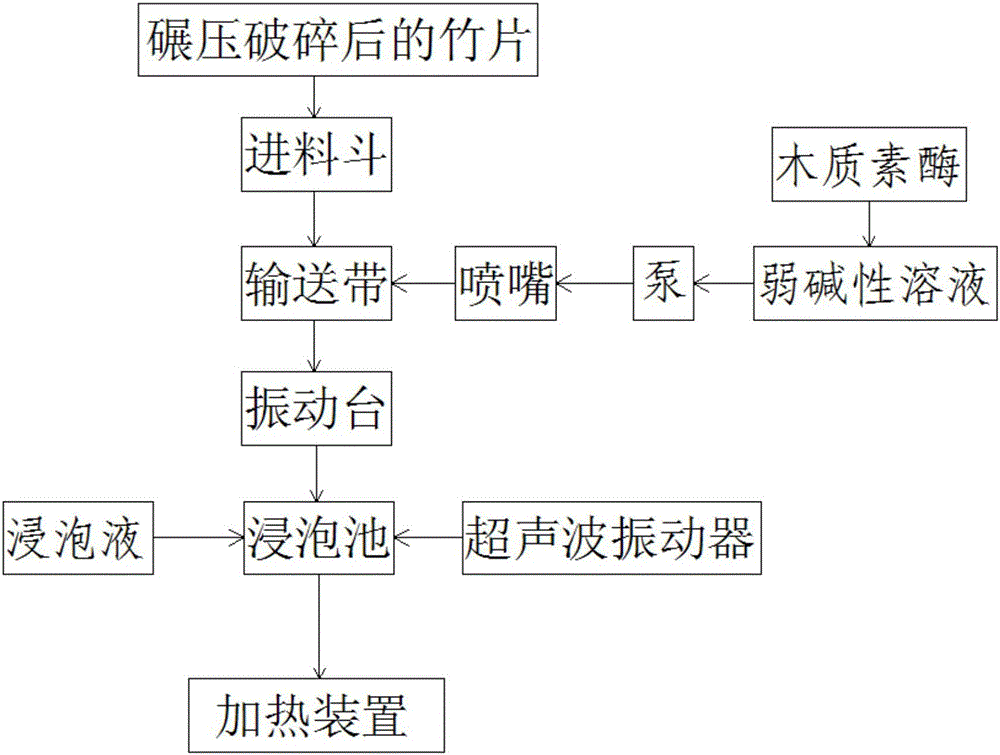

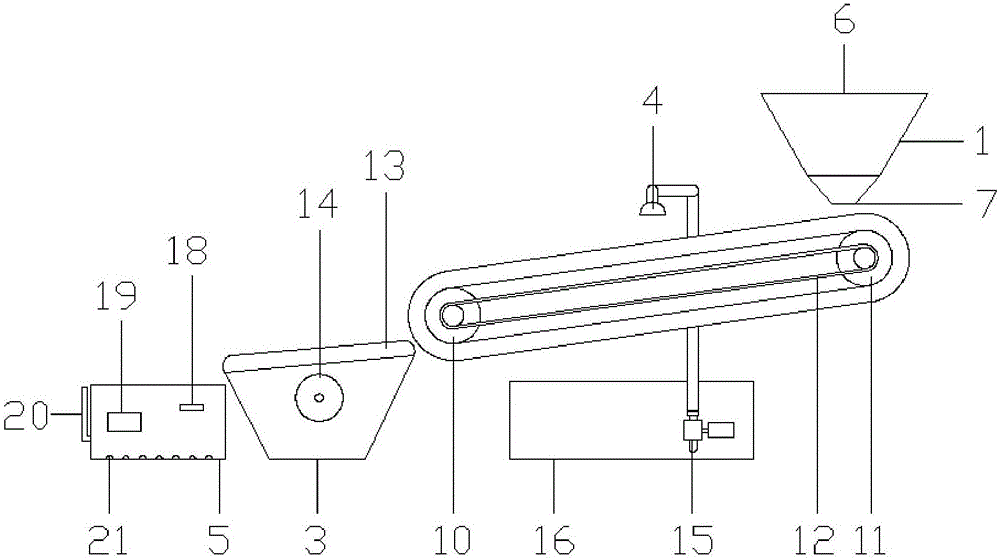

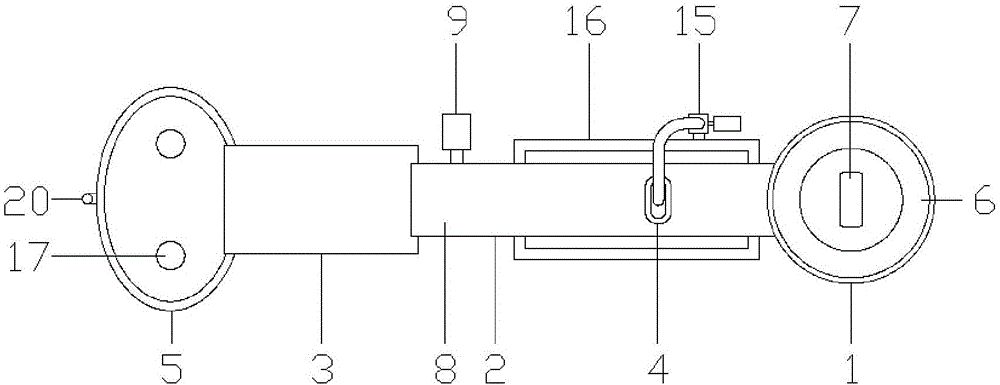

[0055] The user uses the present invention, a bamboo soaking process that reduces the loss of bamboo kun. When the user uses it, he pours a large amount of rolled and crushed bamboo chips to be soaked into the feeding hopper, and the material is evenly distributed by the outlet of the feeding hopper. After entering the conveyor belt, the motor with reducer drives the driving wheel, and the driving wheel drives the driven wheel through the chain, so that the conveyor belt on the driven wheel and the driving wheel moves, and the crushed bamboo chips on the conveyor belt go to the conveyor belt. Conveying in the direction of the vibrating table, when the conveyor belt is conveying the rolled and crushed bamboo chips, the nozzle set above the conveyor belt will spray the weak alkaline solution and / or the soaking liquid in the soaking pool to the rolled and crushed bamboo chips through the pump. On the sheet, clean the dust and debris on the rolled and crushed bamboo chips, and at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com