Intelligent robot for spraying outer wall of high-rise building

A technology for intelligent robots and high-rise buildings, applied in construction, building structure, manipulators, etc., can solve problems such as dangerous operation, high cost, unsustainable material supply and spraying construction, and achieve the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

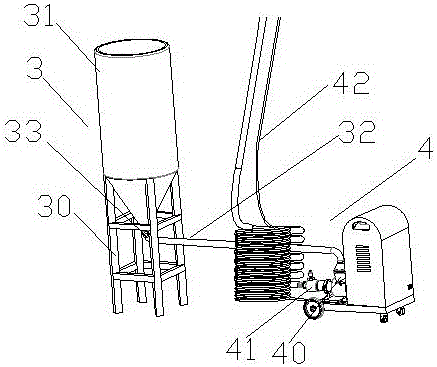

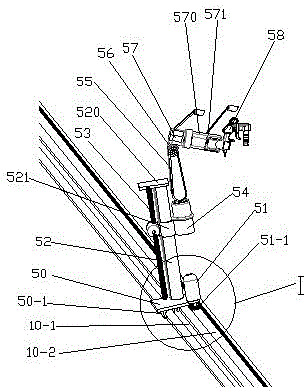

[0037] see Figure 1 to Figure 5 , the present invention is: a kind of high-rise building external wall spraying intelligent robot, wherein, comprise hanging basket 1, the automatic lifting mechanism 2 that is arranged on the two ends of hanging basket 1, the spray material automatic feeder 3 that is respectively arranged on the bottom of hanging basket 1, The spraying power drive mechanism 4, and the mobile robot arm bending and stretching spraying mechanism 5 arranged on the double track 10 at the top of the hanging basket 1.

[0038] The mobile robot arm bending and stretching spraying mechanism 5 comprises a mobile base 50, a drive motor 51 arranged on one side of the top surface of the mobile base 50, and a driving gear I51-1 is arranged on the output shaft of the drive motor 51, which is located on one side of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com