Multi-station continuous grinding device and method for guide vane

A guide vane and multi-station technology, which is applied in grinding/polishing equipment, grinding machines, manufacturing tools, etc., can solve the problems of complex process switching process, low dimensional accuracy, and low processing efficiency, so as to improve the processing pass rate and improve The effect of processing efficiency and reducing the number of tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

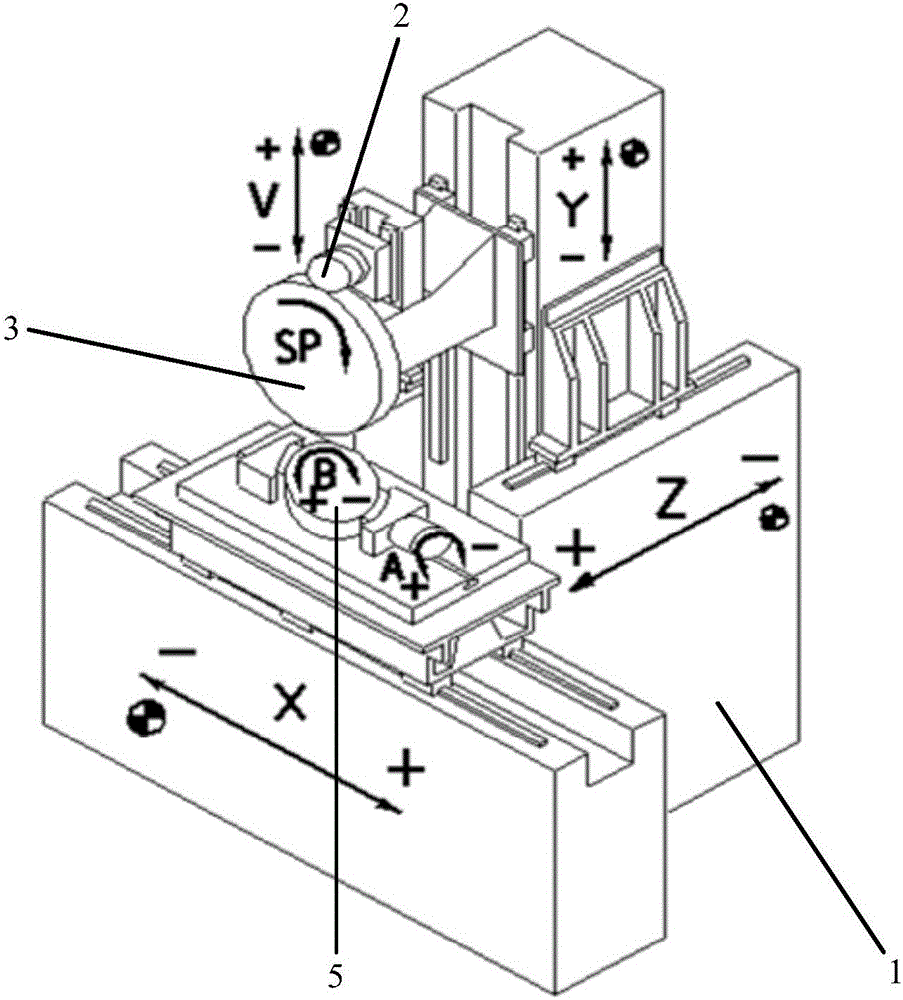

[0055] In order to solve the problem that the existing grinding method has different fixtures, grinding wheels and rollers used in different areas of processing the guide vane 47, resulting in complicated process switching process, low processing efficiency and low dimensional accuracy of the processed guide vane 47, Such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention provides a multi-station continuous grinding device for guide vanes. The multi-station continuous grinding device for guide vanes includes: a four-axis linkage slow-feed grinder 1, a roller 2, a grinding wheel 3 and a fixture 4, and the roller 2 is installed on the roller shaft of the four-axis slow-feed grinding machine 1, the grinding wheel 3 is installed on the grinding wheel shaft of the four-axis slow-feed grinder 1, and the fixture 4 is installed on the rotary table 5 of the four-axis slow-feed grinder 1 ;

[0056] Such as Figure 4 As shown, the side of the roller 2 ...

Embodiment 2

[0079] The present invention provides a method for processing guide vanes using the multi-station continuous grinding device for guide vanes of the present invention, the method comprising:

[0080] Step 1, such as Figure 7 As shown, tighten the fifth compression screw 34 of the basin back positioning and clamping mechanism, so that the fifth compression screw 34 presses against the end of the blade body and basin of the basin back positioning and clamping mechanism towards the pressure plate 37, and the blade body and basin towards the pressure plate 37. The other end presses the second spring 38 of the positioning and clamping mechanism on the back of the basin to release the basin to the positioning and clamping mechanism;

[0081] When the fifth compression screw 34 is tightened, the fifth compression screw 34 will press the end of the blade body basin towards the pressure plate 37. Since the blade body basin phase pressure plate is installed on the bottom surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com