Forming and assembling tool and manufacturing method for composite unmanned aerial vehicle horizontal tails

A composite material and assembling tooling technology, applied in the field of unmanned aerial vehicles, can solve the problems of poor consistency between the left and right parts of the horizontal tail, high cost, unfavorable consistency of the horizontal tail installation angle and dihedral angle, etc. Guaranteed effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

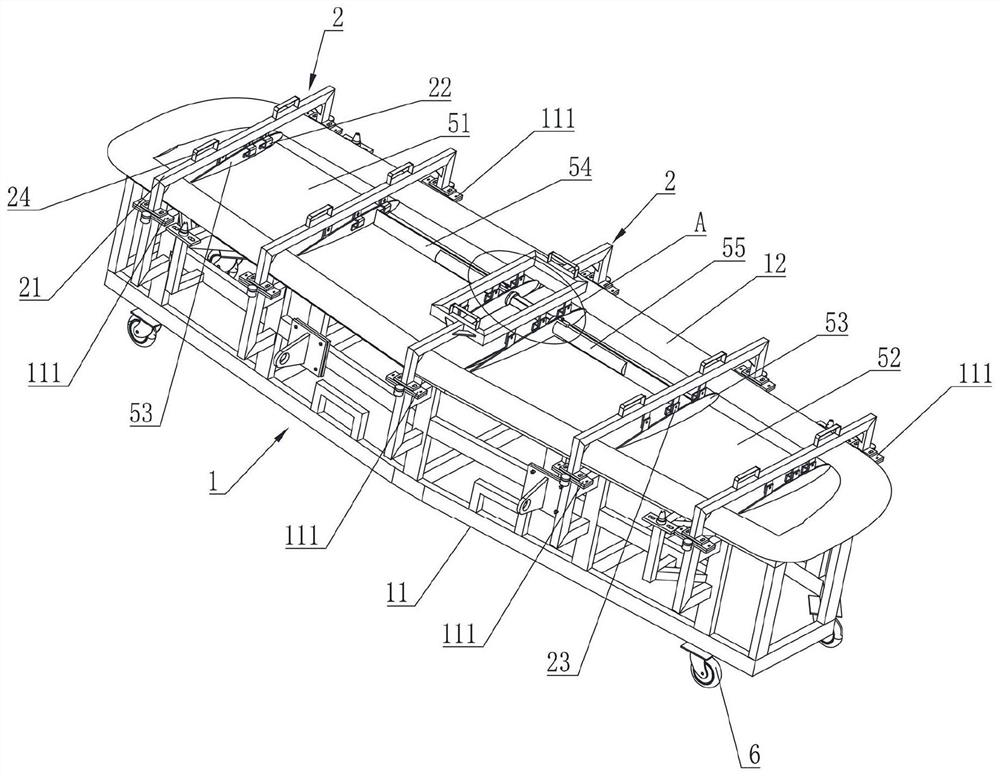

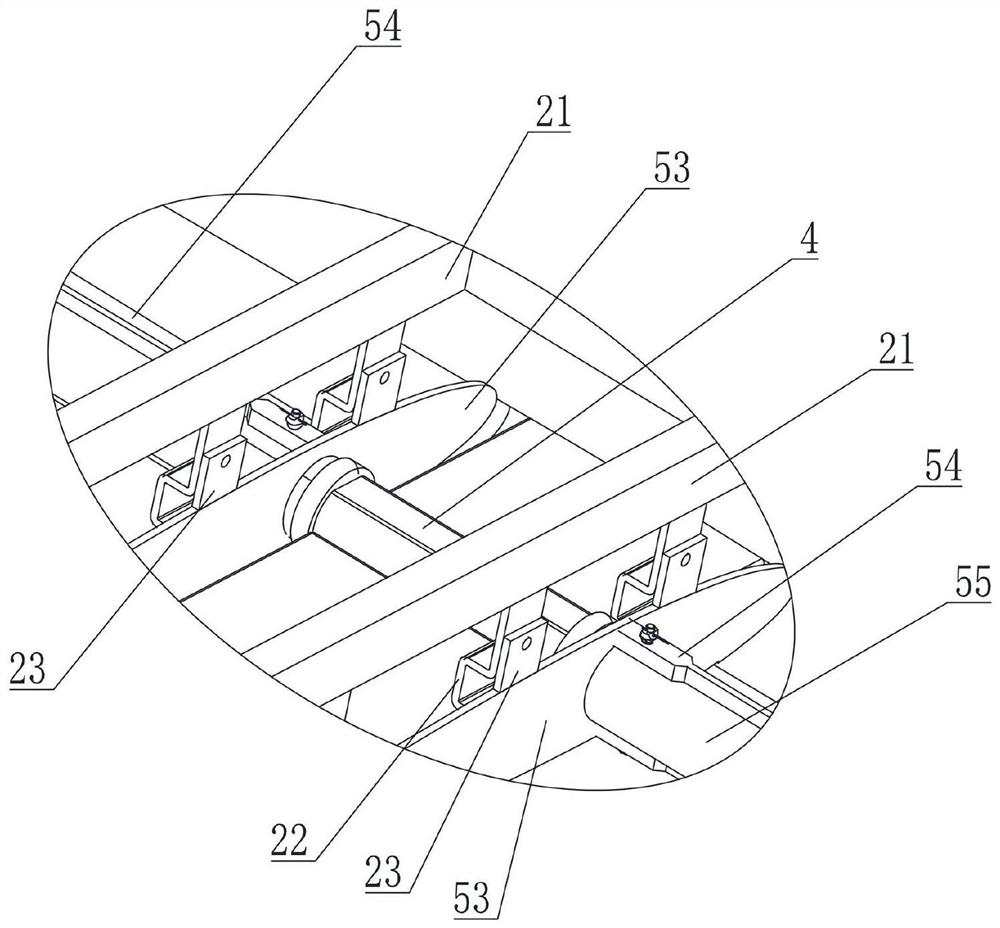

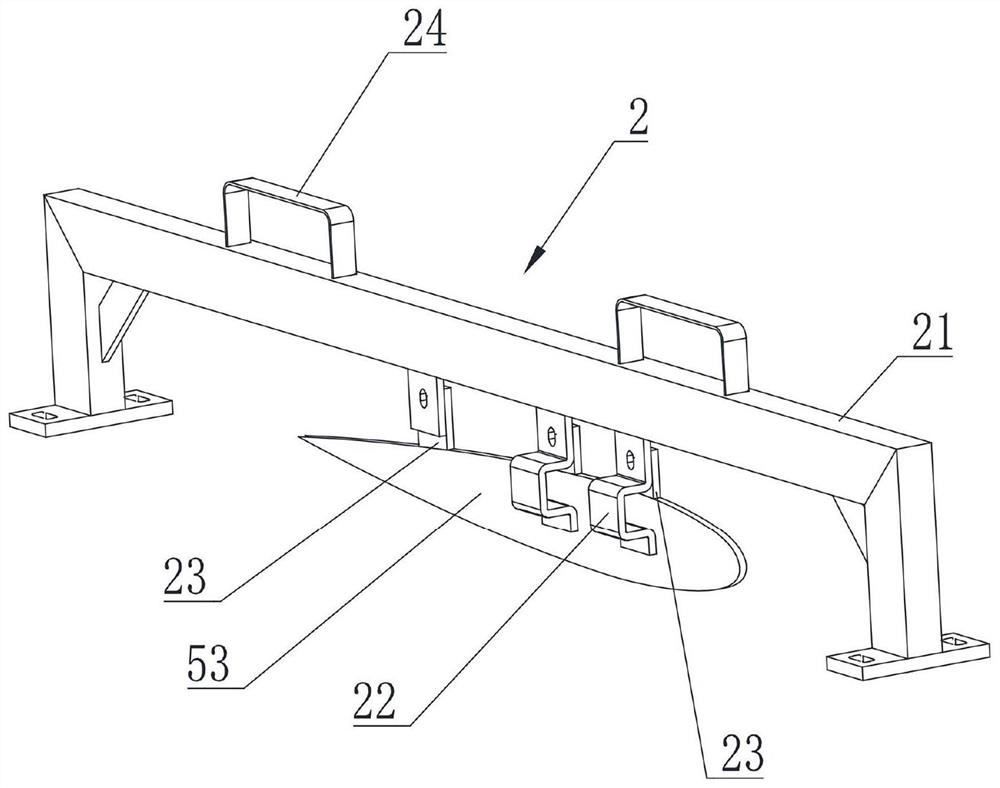

[0044] see Figure 1-Figure 5 As shown, the forming and assembling tool for the horizontal tail of the composite drone provided by the embodiment of the present invention includes a first side forming and assembling part 1 , a second side forming and assembling part 3 , a positioning shaft 4 , and a plurality of pressurized positioning parts 2 .

[0045] see figure 1 with figure 2 As shown, the first side molding assembly part 1 includes a first support frame 11 and a first side skin molding part 12, first positioning installation parts 111 are provided on both sides of the first support frame 11, and the first side skin molding part 12 is installed on the first support frame 11 and is located between the first positioning installation parts 111 on both sides. The upper side of the first side skin molding part 12 is provided with a first side left skin molding cavity and a first side right Skin molding cavity. That is, the first side skin forming part 12 can mold the first...

Embodiment 2

[0063] The second embodiment is a method for manufacturing the flat tail of a composite unmanned aerial vehicle, which can be manufactured using any one of the molding and assembly tooling in the first embodiment, including the following steps:

[0064] S1. Prepare the first left skin, the first right skin, the second left skin and the second right skin:

[0065] Lay prepreg in the first side left skin molding cavity, the first side right skin molding cavity, the second side left skin molding cavity and the second side right skin molding cavity, and perform sealing treatment after the laying is completed Put the first side molding assembly part and the second side molding assembly part into the oven as a whole, vacuumize and heat up to obtain the cured first side left skin, first side right skin, second side left skin and second side skin side right skin;

[0066] S2. Prepare the left skeleton and the right skeleton:

[0067] Lay a single-sided adhesive release cloth on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com